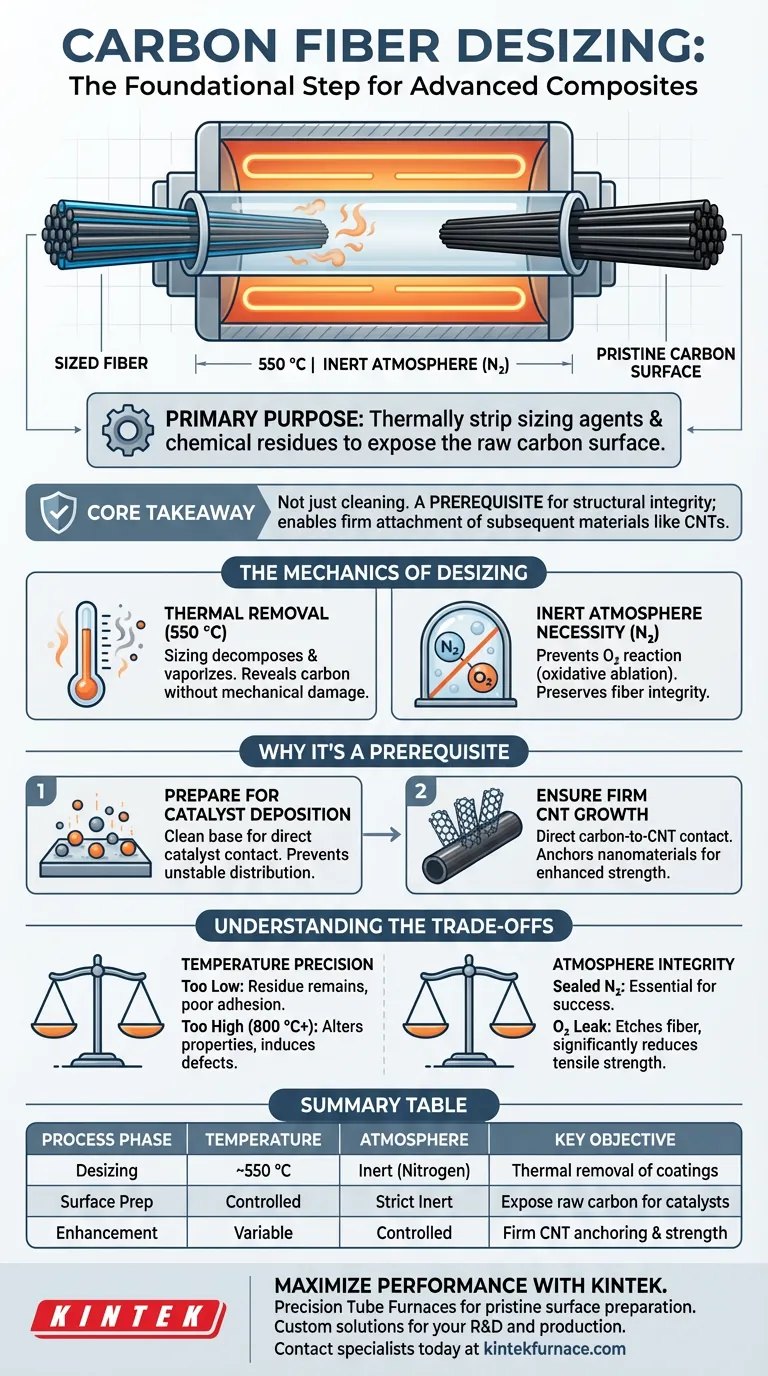

The primary purpose of using a tube furnace during the desizing phase is to thermally strip sizing agents and chemical residues from the carbon fiber surface.

By baking the original carbon fibers at approximately 550 °C within an inert atmosphere, the furnace removes the protective polymer coating (sizing) applied during initial manufacturing. This process exposes the raw carbon surface, creating a pristine baseline required for advanced modifications.

Core Takeaway Desizing is the foundational step for interface engineering in carbon fiber composites. It is not merely a cleaning process, but a prerequisite for structural integrity; without removing these residues, subsequent materials like carbon nanotubes (CNTs) cannot firmly attach to the fiber.

The Mechanics of Desizing

Thermal Removal of Sizing Agents

The tube furnace provides a controlled high-temperature environment to burn off the commercial "sizing"—a thin polymer coating originally applied to protect the fiber during handling.

At 550 °C, these organic sizing agents decompose and vaporize. This reveals the underlying carbon structure without mechanically damaging the fiber.

The Necessity of an Inert Atmosphere

A tube furnace is critical because it allows for a strictly controlled inert atmosphere (typically nitrogen) during the heating process.

If this process were conducted in air, the oxygen would react with the carbon at these temperatures, leading to oxidative ablation (burning) of the fiber itself. The tube furnace ensures only the sizing is removed, while the carbon fiber remains intact.

Why Desizing is a Prerequisite

Preparing for Catalyst Deposition

The immediate goal of desizing is to provide a clean base for the deposition of catalysts.

If residues remain, the catalyst particles used in subsequent steps will sit on top of the sizing rather than the carbon. As the sizing degrades or shifts, the catalyst distribution becomes unstable.

Ensuring Firm CNT Growth

The ultimate objective often involves growing carbon nanotubes (CNTs) on the fiber surface to enhance composite strength.

For CNTs to grow firmly and anchor into the fiber, they require direct contact with the carbon substrate. Desizing removes the physical barrier between the fiber and the new nanomaterial, preventing weak interfaces that would fail under stress.

Understanding the Trade-offs

Temperature Precision vs. Fiber Damage

While the tube furnace enables precise heating, temperature control is paramount.

If the temperature is too low, sizing residues will remain, leading to poor adhesion of future coatings. If the temperature exceeds the specific desizing window (e.g., approaching carbonization temperatures of 800 °C+ used for other precursors), you risk altering the fiber's intrinsic mechanical properties or inducing unwanted defects.

Atmosphere Integrity

The effectiveness of the process relies entirely on the seal and flow of the inert gas.

Even a minor leak in the tube furnace environment introduces oxygen. At 550 °C, oxygen entry does not just clean the fiber; it begins to etch and degrade the fiber diameter, significantly reducing the tensile strength of the final material.

Making the Right Choice for Your Goal

Whether you are preparing fibers for research or industrial application, the desizing parameters must align with your downstream processing needs.

- If your primary focus is Surface Purity: Ensure your furnace maintains a steady 550 °C to fully decompose organic residues without thermal overshoot.

- If your primary focus is Composite Strength (CNT Grafting): Verify that the inert atmosphere is strictly maintained to prevent surface pitting, which ensures the CNTs anchor to a smooth, undamaged substrate.

The success of any advanced carbon fiber modification relies entirely on the quality of this initial surface preparation.

Summary Table:

| Process Phase | Temperature | Atmosphere | Key Objective |

|---|---|---|---|

| Desizing | ~550 °C | Inert (Nitrogen) | Thermal removal of polymer coatings/sizing |

| Surface Prep | Controlled | Strict Inert | Exposing raw carbon for catalyst deposition |

| Enhancement | Variable | Controlled | Ensuring firm CNT anchoring and interface strength |

Maximize Your Material Performance with KINTEK

Precision desizing is the foundation of high-performance carbon fiber composites. At KINTEK, we provide the advanced thermal technology required to achieve pristine surface preparation without compromising fiber integrity.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems. Our high-temp lab furnaces are fully customizable to meet your unique desizing parameters and atmosphere requirements.

Ready to elevate your research and production standards?

Contact our specialists today to find your custom furnace solution

Visual Guide

References

- Suma Ayyagari, Marwan Al‐Haik. Mitigating Crack Propagation in Hybrid Composites: An Experimental and Computational Study. DOI: 10.3390/jcs8040122

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the function of a high-temperature tube furnace in the synthesis of SPC-Fe? Master Graphitic Carbon Production

- How does a tube furnace achieve precise control over product components? Master Cottonseed Pyrolysis with Precision

- How does a high-temperature tube reactor system simulate industrial environments for evaluating catalyst performance?

- What critical reaction conditions are provided by a tube furnace for NiS2 synthesis? Achieve Pure Phase Results

- How does the versatility of a split tube furnace benefit research and industrial processes? Enhance Efficiency and Flexibility

- What are the advantages of a dual-zone tube furnace for Ti3C2Tx MXene? Master Precise Sulfurization Kinetics

- What materials are required for high-temperature operation in tube furnaces? Choose the Right Tube for Your Lab

- What are the benefits of Tube Furnaces? Achieve Precision, Control, and Versatility in Thermal Processing