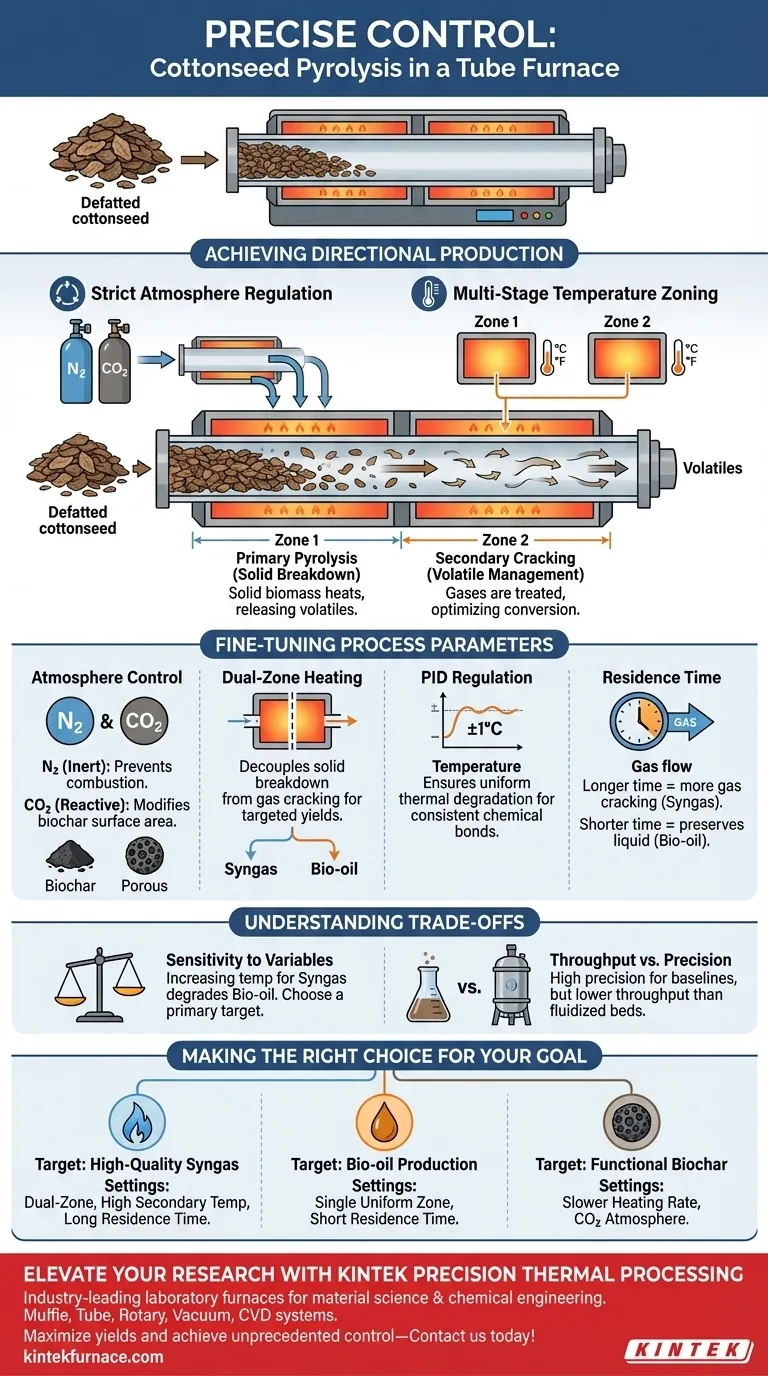

Precise control is achieved through the strict regulation of reaction atmospheres combined with multi-stage temperature zoning. By utilizing inert (N2) or reactive (CO2) environments alongside independent heating zones, the furnace allows you to decouple primary pyrolysis from the secondary cracking of volatiles, thereby dictating the specific yield of syngas, bio-oil, and biochar.

The core advantage of a tube furnace is its ability to facilitate "directional production," allowing you to tune thermal energy and residence time to target specific chemical compositions rather than accepting a random distribution of byproducts.

The Mechanics of Directional Production

Controlling the Atmosphere

The foundational layer of control is the gas environment. A tube furnace seals the defatted cottonseed in a specific atmosphere, typically using Nitrogen (N2) for inert pyrolysis or Carbon Dioxide (CO2) for reactive processes.

By eliminating uncontrolled oxygen, you prevent combustion and ensure the breakdown is purely thermal. Using a reactive atmosphere like CO2 can further modify the resulting biochar, potentially enhancing its surface area and catalytic activity.

The Role of Dual-Zone Configurations

To achieve high specificity in product components, modern tube furnaces often utilize a dual-zone configuration.

The first zone is dedicated to primary pyrolysis, where the solid cottonseed is heated to release volatiles. The second zone manages the secondary cracking of those volatiles.

Separating these stages allows you to treat the solid biomass and the resulting gases differently, optimizing the conversion of heavy tars into lighter, higher-quality syngas or bio-oils.

Fine-Tuning Process Parameters

Precision Temperature Regulation

Achieving consistent product components requires exact thermal stability. Advanced tube furnaces employ PID (Proportional-Integral-Derivative) controllers to regulate heating elements with extreme precision.

This technology ensures the temperature field remains uniform (often within ±1°C to ±5°C). This uniformity is critical for the orderly thermal degradation of cellulose, hemicellulose, and lignin, ensuring that the chemical bonds break exactly as intended.

Managing Residence Time

The duration that volatile gases spend in the heated zone significantly alters the final product.

By adjusting the gas flow rate and the length of the heated zone, you control the residence time. Longer residence times at high temperatures encourage further cracking of long-chain hydrocarbons into non-condensable gases (syngas), while shorter times favor the preservation of liquid components (bio-oil).

Understanding the Trade-offs

Sensitivity to Operating Variables

While the tube furnace offers high precision, the "directional production" of specific components is highly sensitive to parameter interplay.

Increasing the temperature to maximize syngas yield, for example, will inevitably degrade the yield of bio-oil. You cannot maximize all three outputs (char, oil, gas) simultaneously; you must choose a primary target and accept losses in other categories.

Throughput vs. Precision

Tube furnaces are primarily experimental tools designed for batch or semi-continuous processing.

While they offer superior control for characterizing the pyrolysis of defatted cottonseed, they generally lack the throughput of fluidized bed reactors. The data gained here is invaluable for establishing baselines, but scaling the precise heating rates (e.g., 10°C/min) to an industrial level presents significant thermal transfer challenges.

Making the Right Choice for Your Goal

To leverage the tube furnace effectively for defatted cottonseed conversion, align your settings with your desired end-product:

- If your primary focus is High-Quality Syngas: Utilize a dual-zone setup with high secondary temperatures to maximize the cracking of volatiles into non-condensable gases.

- If your primary focus is Bio-oil Production: prioritize a single, uniform heating zone with shorter gas residence times to prevent secondary cracking of the vapors.

- If your primary focus is Functional Biochar: Employ a slower heating rate and potentially a CO2 atmosphere to enhance the pore structure and catalytic properties of the solid residue.

By treating the tube furnace as a precision instrument rather than a simple oven, you transform waste biomass into valuable, chemically specific resources.

Summary Table:

| Control Parameter | Mechanism | Impact on End-Product |

|---|---|---|

| Atmosphere Control | N2 (Inert) or CO2 (Reactive) | Prevents combustion; modifies biochar surface area and catalytic activity. |

| Dual-Zone Heating | Primary pyrolysis vs. Secondary cracking | Decouples solid breakdown from gas cracking to optimize syngas vs. bio-oil yield. |

| PID Regulation | High-precision thermal stability | Ensures uniform degradation of cellulose and lignin for consistent chemical output. |

| Residence Time | Adjusted gas flow rates | Controls the extent of hydrocarbon cracking; longer times favor gas, shorter favor oil. |

Elevate Your Research with Precision Thermal Processing

Ready to transform biomass waste into high-value resources? KINTEK provides industry-leading laboratory furnaces designed for the exact needs of material science and chemical engineering.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique research requirements. Whether you are targeting high-purity syngas or functional biochar, our equipment delivers the thermal uniformity and atmospheric control you need for "directional production."

Maximize your yields and achieve unprecedented process control—Contact us today to find your custom furnace solution!

Visual Guide

References

- Gyeongnam Park, Eilhann E. Kwon. Use of defatted cottonseed-derived biochar for biodiesel production: a closed-loop approach. DOI: 10.1007/s42773-024-00394-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do high-temperature tube furnaces optimize the performance of ceramic materials during post-sintering annealing?

- What is the primary role of a tube furnace in the preparation of biochar? Master Precise Pyrolysis Controls

- What are the advantages of using a fixed-bed continuous flow tube reaction system? Unlock Precision CO2 Hydrogenation

- What is the function of a tube furnace during the hydrogen reduction phase? Optimize Catalyst Microstructures

- How does a tube furnace facilitate the annealing process for Antimony-doped ZnSe and PbSe thin films? Key Performance Tips

- What metallurgical processes benefit from tube furnaces? Achieve Precise Heat Treatment and Material Control

- What function does a high-purity quartz tube serve during the vapor-phase synthesis of MoS2? Key Roles & Benefits

- What role does a high-temperature tube furnace play in biomass-derived carbon? Unlock Advanced Material Synthesis