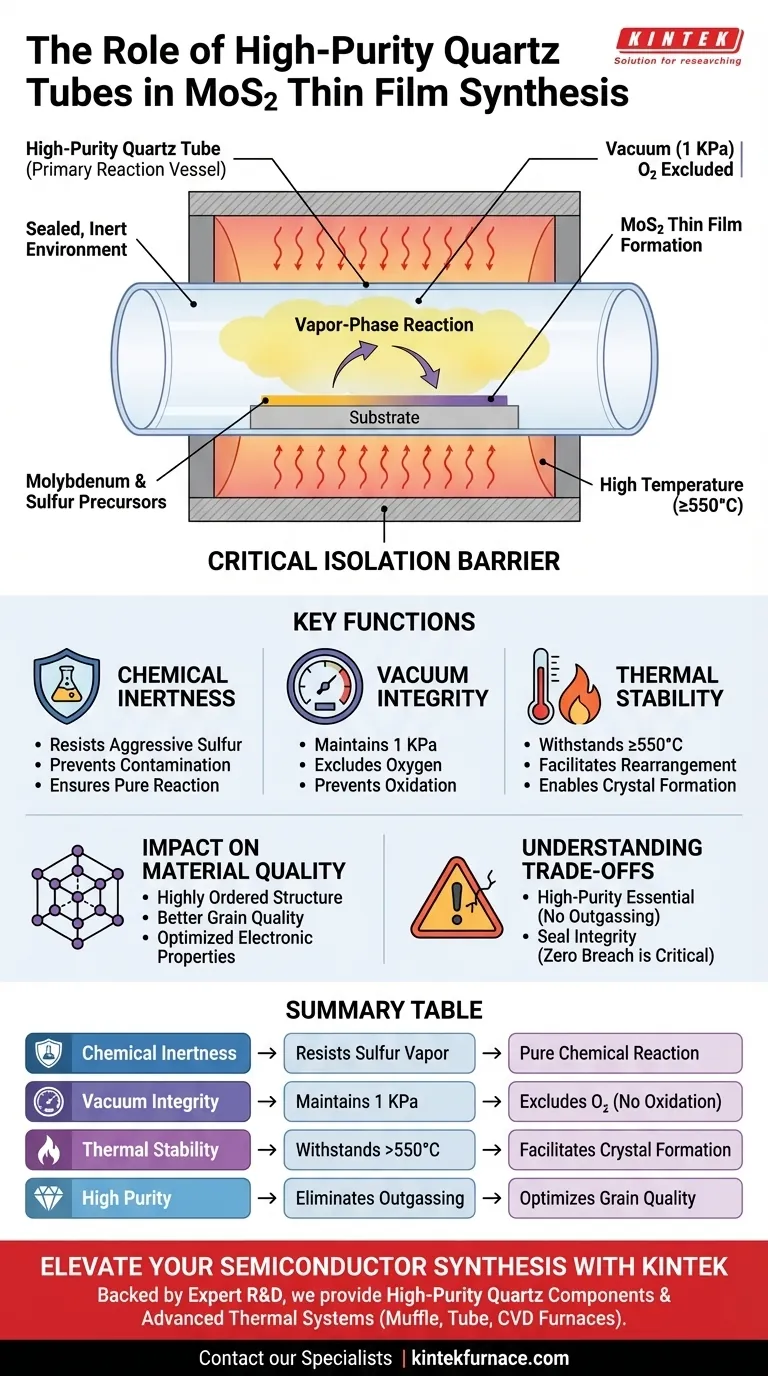

A high-purity quartz tube functions as the primary reaction vessel during vapor-phase synthesis, creating a sealed, inert environment where molybdenum and sulfur can react without contamination. It serves the dual purpose of withstanding temperatures exceeding 550°C while maintaining a vacuum-tight barrier to exclude atmospheric oxygen, ensuring the precursors react thoroughly to form pure Molybdenum Disulfide (MoS2).

The quartz tube acts as a critical isolation barrier, allowing aggressive chemical reactions to occur at high heat and low pressure while preventing the reaction chamber itself from degrading or contaminating the sensitive thin film.

The Role of Quartz in Vapor-Phase Synthesis

Creating a Chemically Inert Environment

The synthesis of MoS2 involves exposing a pre-deposited molybdenum layer to sulfur vapor. Sulfur is chemically aggressive, particularly at high temperatures.

High-purity quartz is essential because it remains chemically stable during this exposure. Unlike metal or lower-grade glass chambers, the quartz tube does not react with the sulfur vapor, ensuring that the sulfur reacts exclusively with the molybdenum target.

Maintaining Vacuum and Excluding Oxygen

Oxygen is the enemy of MoS2 synthesis. If oxygen is present, the molybdenum will oxidize rather than form the desired sulfide.

The quartz tube provides a secure vacuum seal, maintaining a controlled atmosphere around 1 KPa. This physical barrier effectively excludes atmospheric oxygen, creating the specific low-pressure conditions required for the vapor-phase reaction to proceed correctly.

Withstanding Thermal Stress

The reaction between sulfur and molybdenum requires significant thermal energy to initiate and sustain.

The tube acts as the core chamber within a furnace capable of reaching temperatures of 550°C and higher. It maintains its structural integrity and vacuum seal at these elevated temperatures, which allows for the atomic rearrangement necessary to form the crystal structure.

The Impact on Material Quality

Facilitating Atomic Rearrangement

While the primary function is protection and containment, the environment created by the tube actively influences the film's structure.

By sustaining high temperatures (often up to 600°C for annealing processes), the tube allows for atomic rearrangement. This helps transform the MoS2 from an amorphous or weakly crystalline state into a highly ordered structure.

Improving Electronic Properties

The isolation provided by the quartz tube directly correlates to the final performance of the thin film.

By preventing contamination and ensuring a thorough reaction, the process results in improved phase stability and better grain quality. This structural purity is required to optimize electrical properties, such as reducing the resistivity of the final semiconductor material.

Understanding the Trade-offs

The Necessity of Purity

Not all quartz is created equal. The requirement for "high-purity" is non-negotiable in this context.

Standard quartz or glass may contain impurities that can outgas under vacuum at high temperatures, contaminating the MoS2 film. If the tube material degrades, even slightly, it introduces foreign atoms that ruin the electronic properties of the synthesis.

Sensitivity to Seal Integrity

The system relies entirely on the tube's ability to hold a seal.

Because the process operates at approximately 1 KPa, even a minor breach or failure in the tube's sealing mechanism will introduce oxygen. This results in immediate degradation of the synthesis process, yielding molybdenum oxide instead of the desired sulfide.

Making the Right Choice for Your Goal

To ensure successful MoS2 synthesis, select your equipment based on your specific purity and temperature requirements.

- If your primary focus is Chemical Purity: Ensure the quartz tube is certified high-purity to prevent outgassing and reaction with sulfur vapor during the synthesis phase.

- If your primary focus is Crystal Quality: Verify the tube and furnace setup can sustain stable temperatures above 600°C to facilitate the atomic rearrangement required for low-resistivity films.

Ultimately, the quartz tube is not just a container; it is the active barrier that makes high-quality semiconductor synthesis possible.

Summary Table:

| Feature | Function in MoS2 Synthesis | Impact on Thin Film |

|---|---|---|

| Chemical Inertness | Resists aggressive sulfur vapor at high heat | Ensures pure chemical reaction without contamination |

| Vacuum Integrity | Maintains stable 1 KPa low-pressure environment | Excludes oxygen to prevent molybdenum oxidation |

| Thermal Stability | Withstands temperatures >550°C | Facilitates atomic rearrangement for crystal formation |

| High Purity | Eliminates material outgassing | Optimizes grain quality and electrical resistivity |

Elevate Your Semiconductor Synthesis with KINTEK

Precision in thin-film synthesis begins with the right environment. At KINTEK, we understand that high-quality MoS2 production requires uncompromising thermal and chemical stability. Backed by expert R&D and manufacturing, we provide high-purity quartz components and advanced thermal systems tailored for CVD and vapor-phase reactions.

Whether you need Muffle, Tube, Rotary, Vacuum, or custom CVD systems, our laboratory high-temp furnaces are designed to meet your unique research needs. Ensure the purity of your materials and the reliability of your results—contact our specialists today to find your perfect custom solution.

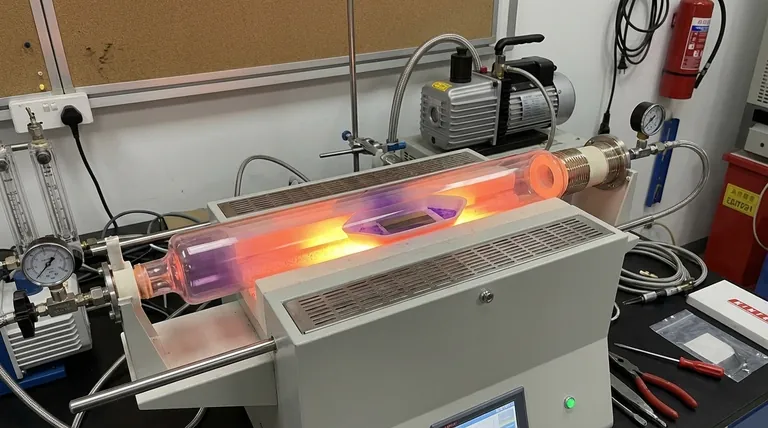

Visual Guide

References

- Saiful Islam, Nowshad Amin. Modulating Molybdenum Disulfide (MoS <sub>2</sub> ) Thin Films Formation via Vapor-Phase Synthesis: Time Variation. DOI: 10.1088/1755-1315/1560/1/012038

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the main operational considerations when using a lab tube furnace? Ensure Precision and Safety in Your Experiments

- How is the quartz tube furnace constructed for vacuum operations? Discover Key Design Elements for High-Temperature Vacuum Processing

- What are the key benefits of using split tube furnaces? Unlock Superior Access and Control for Your Lab

- How is a laboratory tube furnace utilized in the thermal shock reduction process to produce RGO?

- What laboratory applications utilize tube furnaces? Essential for Material Synthesis and Heat Treatment

- Why do vacuum tube furnaces require strict pressure control for Borophene synthesis? Master Single-Phase Integrity

- What specific process conditions does a high-temperature tube furnace provide for carbon black activation? Maximize Yield

- Why is a high-temperature tube furnace required for the preparation of barium ferrite? Achieve Optimal Magnetism