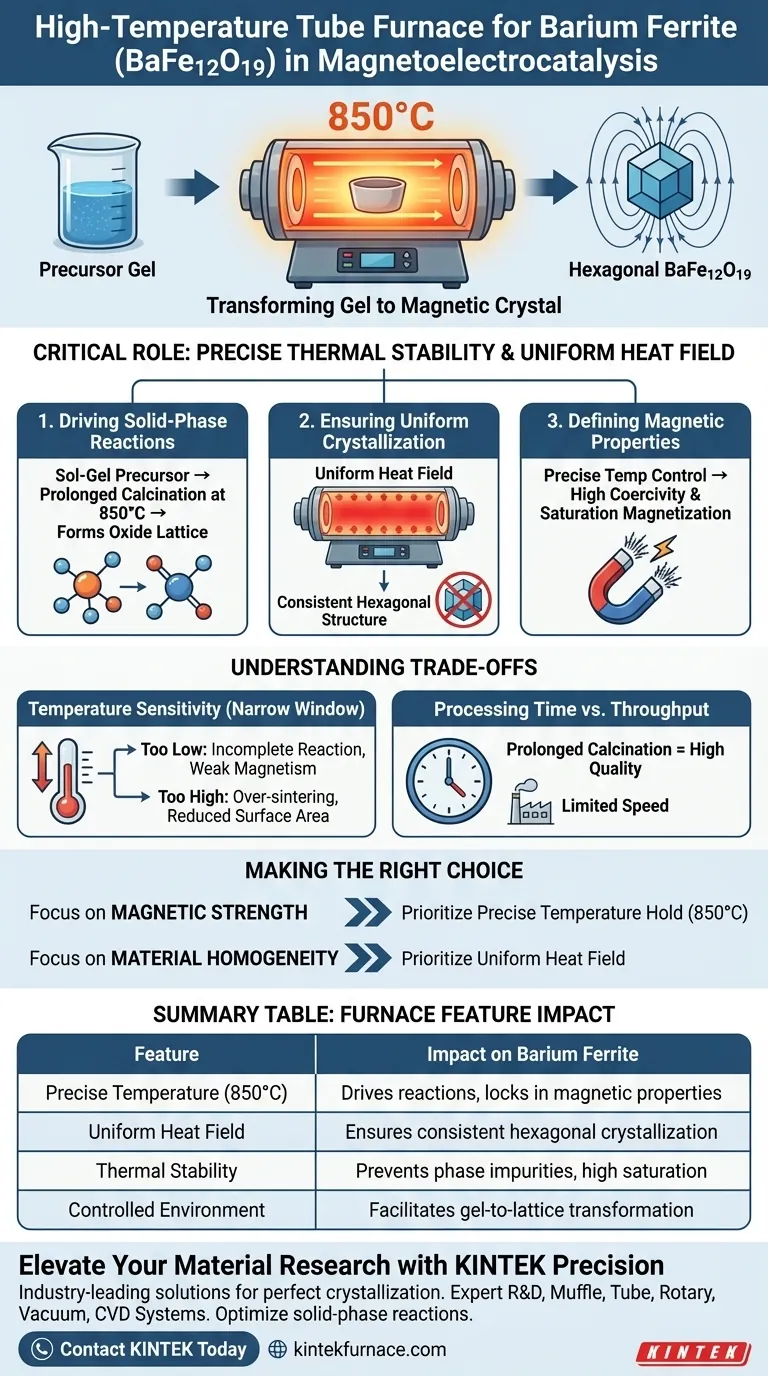

A high-temperature tube furnace is required to provide the precise thermal stability and uniform heat field necessary to crystallize the precursor gel into the specific hexagonal structure of barium ferrite (BaFe12O19). Without the controlled environment of the furnace, typically maintained at temperatures around 850°C, the material cannot undergo the solid-phase reactions needed to achieve the high coercivity and saturation magnetization required for effective magnetoelectrocatalysis.

The tube furnace is not just a heating element; it is a structural determinant. It ensures the uniform temperature distribution required to drive solid-phase reactions, directly dictating the magnetic strength and catalytic efficiency of the final material.

The Critical Role of Thermal Stability

To transform a chemical precursor into a functional magnetic catalyst, you must control the thermal environment with extreme precision. The tube furnace is the tool that bridges the gap between raw chemistry and material physics.

Driving Solid-Phase Reactions

The preparation of barium ferrite often utilizes a citric acid sol-gel process. This results in a precursor gel that is chemically reactive but structurally undefined.

To convert this gel into a useful material, it must undergo prolonged calcination. The tube furnace creates the sustained high-temperature environment (e.g., 850°C) required to drive the solid-phase reactions that consume the organic components and form the oxide lattice.

Ensuring Uniform Crystallization

The geometry of the tube furnace creates a highly uniform heat field. This uniformity is non-negotiable for forming the hexagonal ferrite structure.

If the heat is uneven, different parts of the sample may crystallize at different rates or into different phases. The tube furnace ensures that the entire sample experiences the exact same thermal history, resulting in a consistent crystal structure throughout the batch.

Defining Magnetic Properties

For magnetoelectrocatalysis, the material's magnetic properties are as important as its chemical composition. The furnace's thermal control directly determines these physical traits.

Specifically, the precise temperature regulation controls the coercivity (resistance to demagnetization) and saturation magnetization (maximum magnetic strength). These properties are "locked in" during the high-temperature crystallization phase managed by the furnace.

Understanding the Trade-offs

While the high-temperature tube furnace is essential, it introduces specific variables that must be managed carefully. The relationship between temperature and performance is not linear.

The Sensitivity of Temperature Control

The primary reference highlights that precise temperature control determines the final material properties. This implies a narrow window of success.

If the temperature is too low, the solid-phase reaction will be incomplete, leading to weak magnetism and poor catalytic performance. Conversely, excessive temperatures can lead to over-sintering, which may reduce the surface area necessary for catalytic reactions, even if magnetic properties are strong.

Processing Time vs. Throughput

Achieving the necessary phase transformation requires prolonged calcination. This makes the tube furnace process time-intensive.

While this ensures high-quality crystallization, it limits the speed of production compared to rapid-heating methods. You are trading manufacturing speed for the superior structural integrity and magnetic performance required for high-end applications.

Making the Right Choice for Your Goal

The tube furnace is a precision instrument. How you utilize it depends on the specific parameters of your research or production goals.

- If your primary focus is Magnetic Strength: Prioritize the precision of the temperature hold at 850°C to maximize coercivity and saturation magnetization.

- If your primary focus is Material Homogeneity: Focus on the uniformity of the heat field within the tube to ensure the entire batch achieves the hexagonal structure without phase impurities.

Success in magnetoelectrocatalysis depends less on the chemistry of the gel and more on the thermal discipline of the furnace.

Summary Table:

| Feature | Impact on Barium Ferrite Preparation |

|---|---|

| Precise Temperature (850°C) | Drives solid-phase reactions and locks in magnetic properties. |

| Uniform Heat Field | Ensures consistent hexagonal crystallization across the entire batch. |

| Thermal Stability | Prevents phase impurities and ensures high saturation magnetization. |

| Controlled Environment | Facilitates the transformation from precursor gel to oxide lattice. |

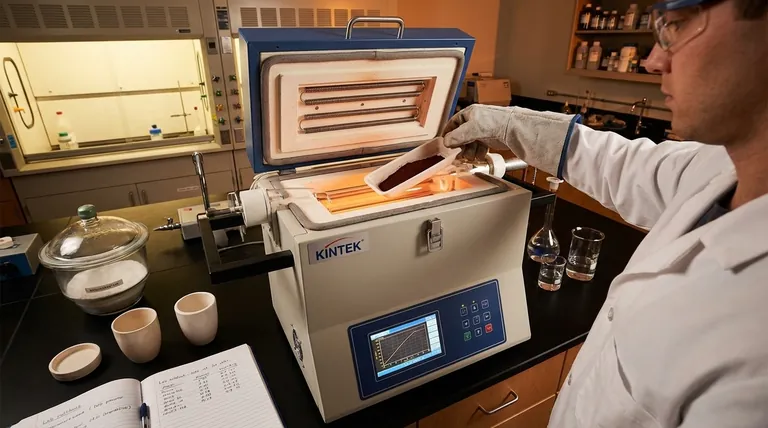

Elevate Your Material Research with KINTEK Precision

High-performance magnetoelectrocatalysis demands absolute thermal discipline. KINTEK provides the industry-leading high-temperature solutions necessary to achieve perfect crystallization in barium ferrite synthesis.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab equipment or a fully customized furnace for unique material needs, KINTEK ensures your research is supported by uniform heat fields and precise thermal control.

Ready to optimize your solid-phase reactions?

Contact KINTEK Today for a Expert Consultation

Visual Guide

References

- Amy Radford, Shik Chi Edman Tsang. Untangling the Mechanisms in Magneto‐Electrocatalytic Oxygen Evolution. DOI: 10.1002/smll.202412852

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How are rotary tube furnaces used in the mining and metallurgy industry? Boost Efficiency in Metal Processing

- What are the common applications of quartz tube furnaces? Unlock Precision in High-Temp Processing

- How does a two-stage heating process in a laboratory tube furnace contribute to the structural formation of SiCN(Ni)/BN?

- What is the function of a high-temperature tube furnace in pp-fiber production? Master Precise Carbonization Control

- What control options are available for tube furnaces? Scale from Simple Heating to Complex Automation

- What is an alumina tube furnace? Essential for High-Temp, Contamination-Free Material Processing

- What are the limitations of vertical tube furnaces? Key Trade-offs for Lab Efficiency

- How does the direct annealing process in a tube furnace affect iridium-based inverse opals? Expert Insights