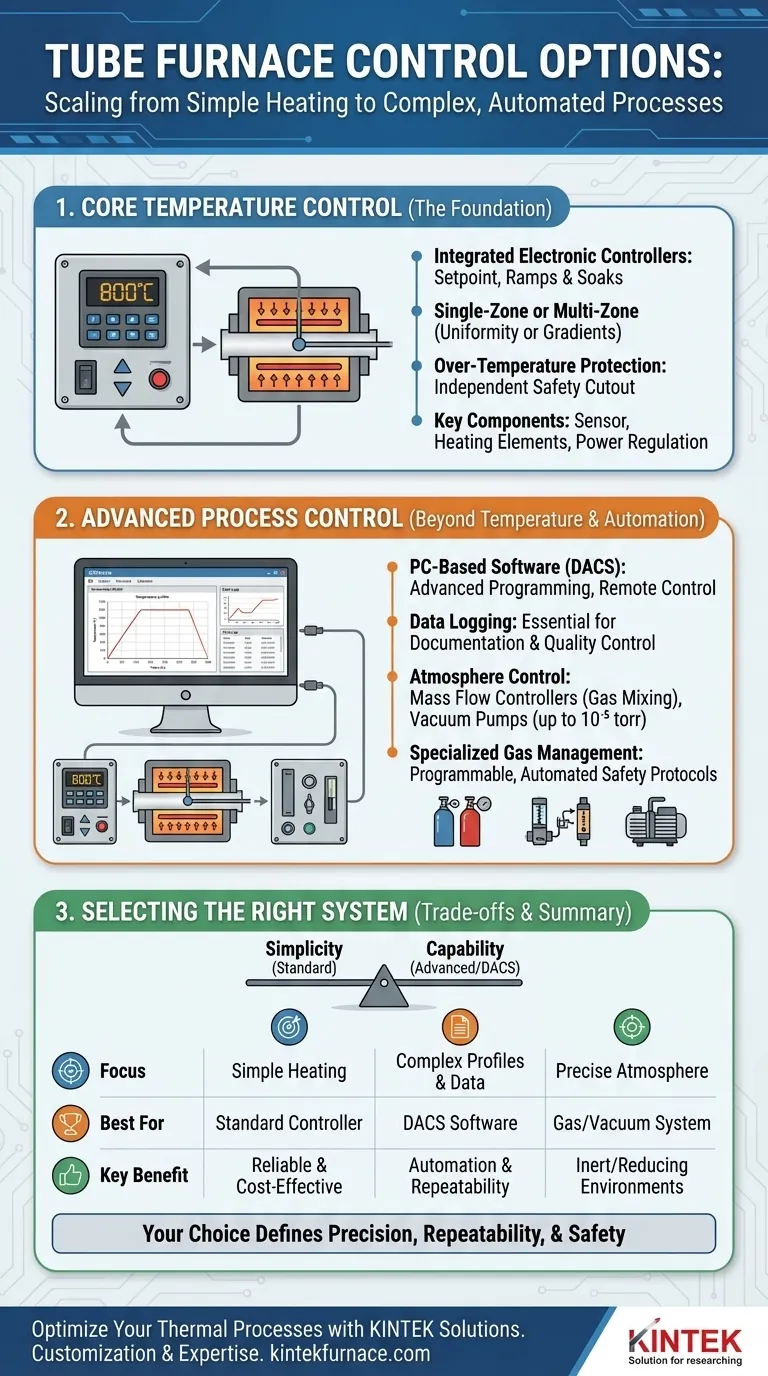

At its core, a tube furnace offers three categories of control: integrated electronic panels for direct temperature management, PC-based software for advanced programming and data logging, and dedicated systems for precise atmosphere and gas management. These options allow you to scale the furnace’s capability from simple heating tasks to complex, automated, and highly documented processes.

The choice of a control system is not merely about setting a temperature. It's a strategic decision that defines the precision, repeatability, and safety of your entire thermal process, from basic heat treatment to sophisticated materials synthesis under controlled atmospheres.

The Foundation: Core Temperature Control

The most fundamental function of any tube furnace is to achieve and maintain a specific temperature. The standard control system is designed to do exactly this with high reliability.

Integrated Electronic Controllers

Nearly all tube furnaces come with a panel-mounted electronic controller. This is the primary user interface for setting the target temperature (setpoint) and, in many cases, programming simple heating and cooling rates (ramps) and holding times (soaks).

These controllers can manage single-zone configurations, where the entire heated length is held at one temperature, or more complex multi-zone setups. Multi-zone control uses multiple independent controllers and sensors to create a highly uniform temperature profile or a specific temperature gradient across the sample.

Over-Temperature Protection

As a critical safety feature, most furnaces include a separate over-temperature controller. This independent system monitors the furnace temperature and will automatically cut power to the heating elements if it exceeds a user-defined safety limit, protecting both the furnace and the user.

Key Control Components

The control system works by reading data from a temperature sensor (typically a thermocouple) placed in the heated zone. The controller then regulates the power sent to the heating elements (such as Kanthal, SiC, or MoSi2) to precisely match the setpoint.

Advanced Process Control: Beyond Temperature

For applications requiring more than just stable heat, advanced systems add layers of automation, data management, and atmospheric control.

Data Acquisition and Control Software (DACS)

PC-based software represents a significant leap in capability. A DACS allows you to design, program, and execute complex thermal profiles with many steps directly from a computer.

Its primary advantages are programmability, remote control, and data logging. This is essential for processes that must be highly repeatable or require detailed documentation for quality control and research purposes.

Atmosphere Control (Gas and Vacuum)

Many processes require heating under specific atmospheric conditions. Advanced control systems integrate with gas delivery and vacuum systems to manage this environment precisely.

This can include using mass flow controllers for mixing multiple gases to create an inert or reducing atmosphere, or controlling a vacuum pump to achieve pressures as low as 10⁻⁵ torr.

Specialized Gas Management Systems

For applications with complex or hazardous gases, a dedicated gas management system (such as SIMGAS4) provides the highest level of control and safety. These systems are fully programmable and can be configured with automated safety protocols and alerts to manage gas flow precisely.

Understanding the Trade-offs

Choosing the right control system involves balancing capability with complexity. Each option presents a different set of benefits and considerations.

Simplicity vs. Capability

A standard electronic controller is intuitive, robust, and perfectly adequate for straightforward heating tasks. Software-based systems offer immense power for automation and data collection but come with a steeper learning curve and require a dedicated PC.

Data Integrity and Repeatability

If your process requires strict documentation for certification or publication, a DACS is non-negotiable. It provides a complete, time-stamped log of all process parameters, ensuring your results are verifiable and repeatable in a way that manual logging cannot match.

Cost and Integration

Advanced control options, including multi-zone configurations, software, and gas management systems, add to the initial cost and complexity of the furnace setup. However, this investment is often justified by the increased process control, safety, and a reduction in manual oversight.

Selecting the Right Control System for Your Goal

Your choice should be driven by the specific demands of your application.

- If your primary focus is simple, consistent heating: A standard, single-zone electronic controller with over-temperature protection is the most reliable and cost-effective solution.

- If your primary focus is complex thermal profiles and data logging: A system with Data Acquisition and Control Software (DACS) is essential for programming, automation, and process documentation.

- If your primary focus is precise atmosphere control: You need a system that integrates mass flow controllers for gas mixing or a turbo vacuum pump, all managed through an advanced software interface.

Ultimately, matching the control system to your operational needs is the key to unlocking the full potential of your tube furnace.

Summary Table:

| Control Option | Key Features | Best For |

|---|---|---|

| Integrated Electronic Controllers | Direct temperature setting, ramps, soaks, over-temperature protection | Simple, consistent heating tasks |

| PC-Based Software (DACS) | Advanced programming, data logging, remote control, automation | Complex thermal profiles and strict documentation |

| Atmosphere and Gas Management | Mass flow controllers, vacuum systems, safety protocols | Precise atmosphere control for inert or reducing environments |

Ready to optimize your thermal processes with the right tube furnace control? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing precision, repeatability, and safety. Contact us today to discuss how we can support your laboratory needs!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right High-Temp Solution