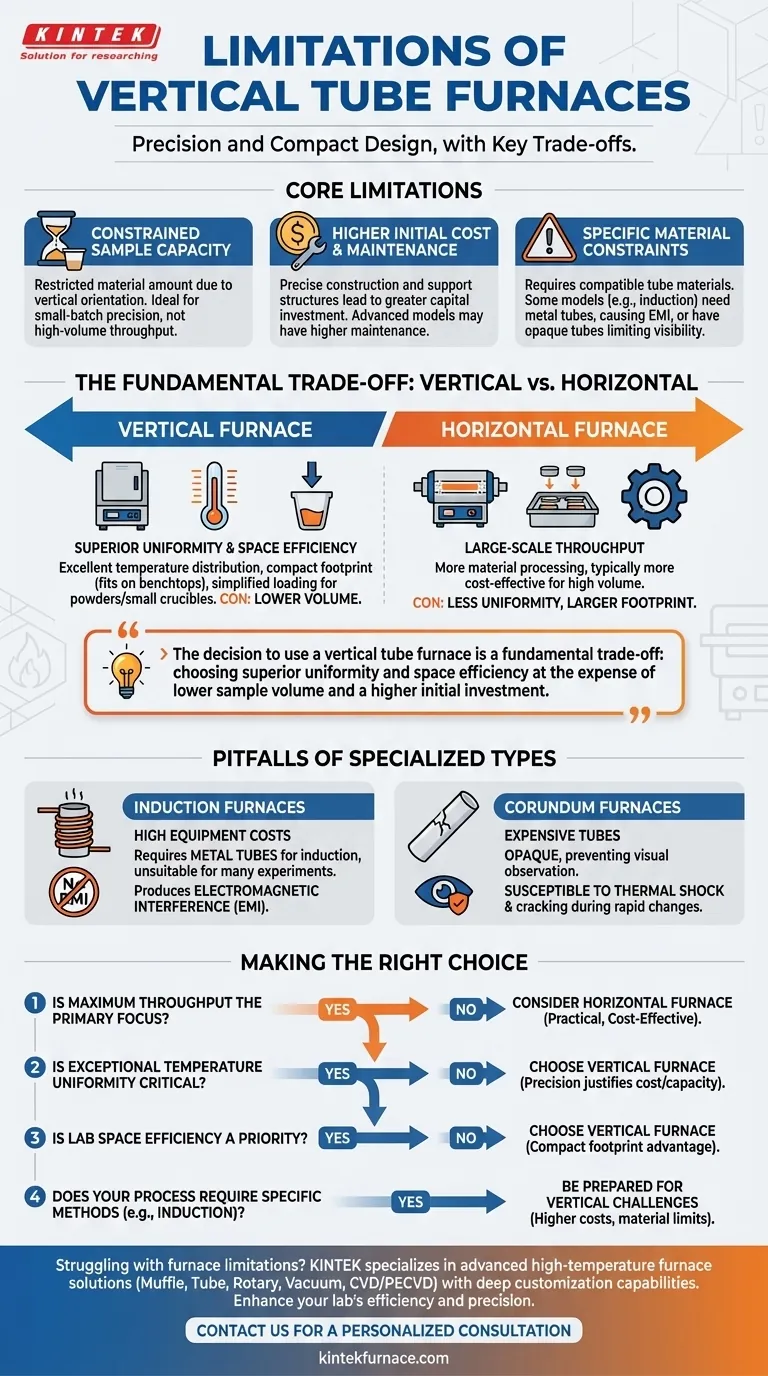

While prized for their precision and compact design, the primary limitations of vertical tube furnaces revolve around their smaller processing capacity, higher initial costs, and specific material constraints. Compared to their horizontal counterparts, vertical furnaces trade large-scale throughput for superior temperature uniformity and a smaller physical footprint.

The decision to use a vertical tube furnace is a fundamental trade-off. You are choosing superior temperature uniformity and space efficiency at the expense of lower sample volume, a higher initial investment, and potentially more complex operational requirements.

Deconstructing the Core Limitations

Understanding the specific drawbacks is the first step in determining if a vertical tube furnace aligns with your operational and budgetary needs. These limitations are not inherent flaws but rather design consequences of their vertical orientation.

Constrained Sample Capacity

The most significant limitation is a smaller working capacity. The vertical orientation restricts the amount of material that can be processed at one time compared to longer, horizontal models.

This makes vertical furnaces ideal for high-precision, small-batch processing or laboratory research but less suitable for applications requiring high-volume throughput.

Higher Initial Cost and Maintenance

Vertical tube furnaces often represent a higher capital investment. This is due to their precise construction needed to ensure thermal uniformity and the complexity of their support structures.

Furthermore, certain advanced models come with higher maintenance requirements, contributing to a greater total cost of ownership over the furnace's lifespan.

Understanding the Trade-offs: Vertical vs. Horizontal

The limitations of a vertical furnace are best understood when compared directly against the alternative. The choice between a vertical and horizontal model is driven by your primary goal.

The Uniformity Advantage

Vertical furnaces provide excellent temperature uniformity along the entire length of the sample. The natural convection currents within the vertical tube contribute to more even heating, which is critical for sensitive materials and processes demanding consistent results.

The Footprint Factor

A key advantage driving their adoption is their compact footprint. Vertical furnaces are perfectly suited for crowded laboratories or facilities where floor space is at a premium, as they can be easily placed on benchtops or integrated into existing setups.

The Loading and Unloading Process

The vertical orientation simplifies the loading and unloading of certain sample types, such as powders or small crucibles that can be easily lowered into the chamber. This makes batch processing highly convenient and repeatable.

Pitfalls of Specialized Furnace Types

Beyond the general limitations, specific types of vertical tube furnaces introduce their own unique challenges. It is critical to match the furnace technology to your specific application to avoid costly incompatibilities.

Induction Furnaces: Power vs. Complexity

Induction heating models are powerful but come with significant drawbacks. They have very high equipment costs due to their complex technology.

Crucially, they require metal furnace tubes to generate heat via electromagnetic induction, making them unsuitable for any experiment incompatible with metal. They also produce electromagnetic interference (EMI) that can disrupt nearby electronic equipment.

Corundum Furnaces: Purity vs. Practicality

Corundum tubes are used for high-purity applications but are expensive. Their primary limitation is that they are opaque, preventing any direct visual observation of the sample during processing.

Additionally, their large thermal expansion coefficient means they are susceptible to stress and potential cracking during rapid temperature changes, requiring careful operational control.

Making the Right Choice for Your Application

Selecting the correct furnace requires a clear understanding of your project's non-negotiable requirements. Use your primary goal as the deciding factor.

- If your primary focus is maximum sample throughput: A horizontal tube furnace is likely the more practical and cost-effective solution.

- If your primary focus is exceptional temperature uniformity for sensitive materials: The precision of a vertical tube furnace justifies its lower capacity and higher cost.

- If your primary focus is lab space efficiency: A vertical tube furnace offers a significant advantage due to its compact, vertical footprint.

- If your process requires specific heating methods (like induction): Be prepared for higher equipment costs, potential EMI, and strict limitations on compatible tube materials.

Understanding these limitations is the key to selecting a furnace that serves as a powerful asset, not a frustrating constraint.

Summary Table:

| Limitation | Description |

|---|---|

| Smaller Processing Capacity | Vertical orientation restricts sample volume, ideal for small-batch precision but not high-throughput applications. |

| Higher Initial Cost | Requires precise construction and support, leading to greater capital investment and maintenance expenses. |

| Material and Operational Constraints | Specific models (e.g., induction) need metal tubes, cause EMI, or have opaque tubes limiting visibility and requiring careful handling. |

Struggling with furnace limitations in your lab? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to overcome capacity, cost, and material challenges. Enhance your lab's efficiency and precision—contact us today for a personalized consultation!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs