At its core, the versatility of a split tube furnace stems directly from its hinged, two-part design. This physical configuration allows operators to place or remove samples and entire experimental apparatuses directly into the heating chamber, rather than sliding them through the ends, dramatically increasing the range of possible applications in both research and industry.

The split tube furnace's defining feature is accessibility. This translates not just to convenience, but to the ability to work with complex setups, perform rapid sample changes, and observe processes in ways that are impractical with traditional, single-piece tube furnaces.

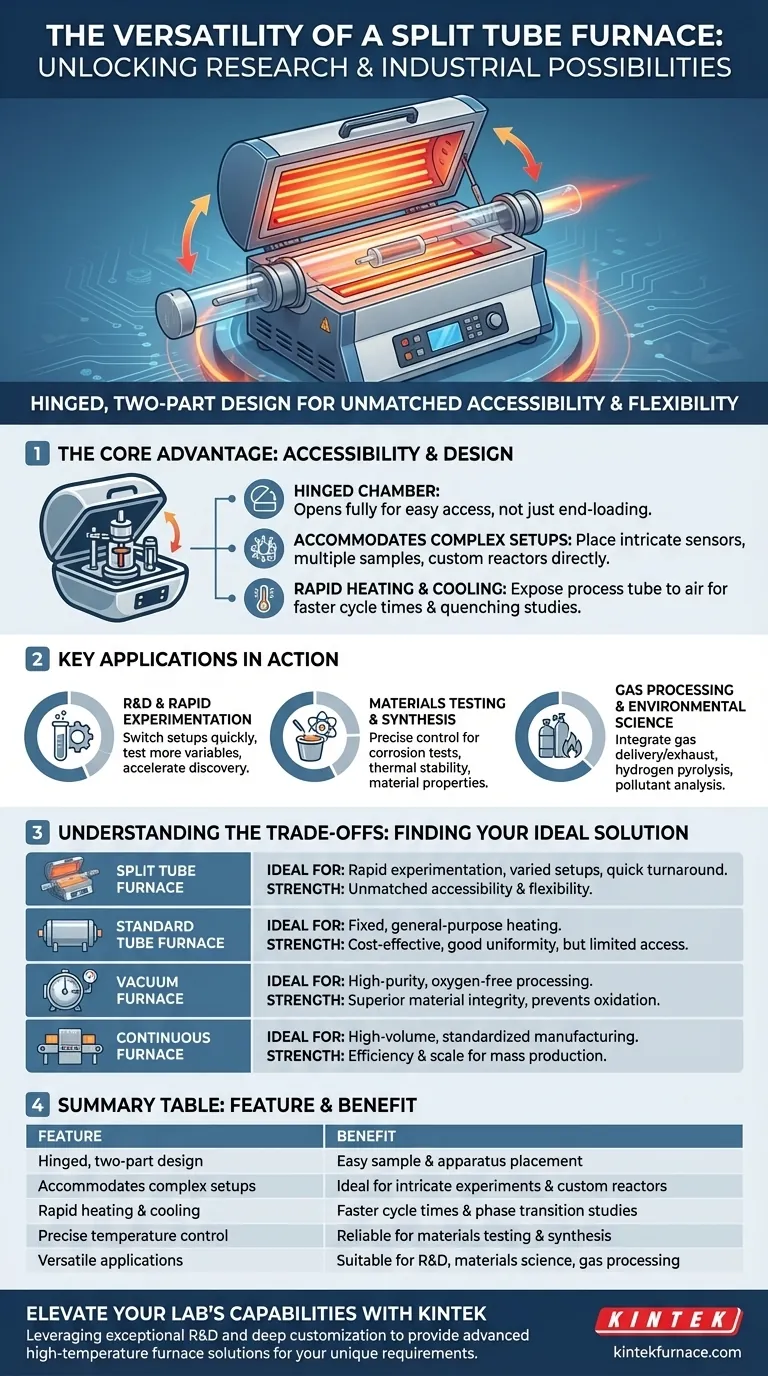

The Source of Versatility: A Design Breakdown

The practical benefits of a split tube furnace are a direct result of its unique mechanical construction. Understanding this design clarifies why it is the preferred choice for specific, demanding tasks.

The Hinged, Two-Part Chamber

Unlike a standard tube furnace, which is a solid cylinder, a split tube furnace is constructed in two halves connected by a hinge. This allows it to open like a clamshell, fully exposing the internal process tube.

This simple design change is the foundation of its flexibility, removing the limitation of having to insert everything from the narrow opening at the end of the tube.

Accommodating Complex Setups

The open-access design is ideal for experiments involving pre-assembled or irregularly shaped apparatuses. Researchers can place intricate sensor arrays, multiple sample holders, or custom reactors directly onto the process tube before closing the furnace around them.

This is a significant advantage in materials science, chemistry, and physics, where experimental setups are often complex and cannot be easily assembled inside a narrow tube.

Enabling Rapid Heating and Cooling

For processes requiring rapid cooling or quenching, an operator can simply open the furnace to expose the process tube to ambient air. This provides a much faster cooling rate than waiting for a standard furnace's insulation to dissipate heat.

This capability is crucial for studying phase transitions in materials and for increasing sample throughput in a busy lab by reducing cycle time.

Key Applications Driven by Versatility

The design advantages of a split tube furnace translate directly into its suitability for a wide range of scientific and industrial applications.

Research & Development (R&D)

In R&D environments, experimental parameters change constantly. The split tube furnace excels here because it dramatically reduces the time needed to switch between different setups.

This efficiency accelerates the pace of discovery, allowing researchers to test more variables in less time.

Materials Testing and Synthesis

The furnace provides the precise temperature control and uniformity needed for reliable materials testing. It is used to simulate high-temperature environments to test for corrosion resistance, thermal stability, and other material properties.

Its ability to accommodate various sample sizes and configurations makes it a workhorse in materials synthesis, catalyst testing, and thermal processing.

Gas Processing and Environmental Science

Split tube furnaces are used in applications like hydrogen pyrolysis and biomass conversion. The easy access allows for the integration of gas delivery and exhaust systems, which are essential for these processes.

In environmental science, they can simulate incineration processes for pollutant analysis or test how new materials withstand extreme environmental conditions.

Understanding the Trade-offs

While highly versatile, the split tube furnace is not the universal solution for all high-temperature applications. Understanding its position relative to other furnace types is key.

vs. Standard Tube Furnaces

A standard, single-piece tube furnace is often more cost-effective and can offer slightly better thermal uniformity, as there is no seam in the insulation or heating elements. However, it completely sacrifices the accessibility and flexibility of a split tube design.

vs. Vacuum Furnaces

While a split tube furnace can be configured to operate under vacuum, a dedicated vacuum furnace is superior for applications requiring a high-purity, oxygen-free environment. Vacuum furnaces are designed from the ground up to prevent contamination and material degradation, making them essential for processing sensitive alloys, brazing, and advanced sintering.

vs. Continuous Furnaces

Continuous furnaces are designed for high-volume, automated industrial production where the same process is repeated endlessly. A split tube furnace is a batch-processing tool, prized for flexibility and custom setups rather than mass throughput.

Making the Right Choice for Your Process

Selecting the correct furnace requires matching the equipment's strengths to your primary operational goal.

- If your primary focus is rapid experimentation and varied setups: The split tube furnace is the ideal choice for its unmatched accessibility and quick turnaround times.

- If your primary focus is high-purity processing without oxidation: A dedicated vacuum furnace provides the controlled atmosphere necessary for superior material integrity.

- If your primary focus is high-volume, standardized manufacturing: A continuous furnace is designed for the efficiency and scale required for mass production.

- If your primary focus is a fixed, general-purpose heating application: A traditional, non-split tube furnace may offer the most cost-effective solution.

Ultimately, the right furnace is the one that removes friction from your specific workflow and empowers you to achieve consistent, reliable results.

Summary Table:

| Feature | Benefit |

|---|---|

| Hinged, two-part design | Easy sample and apparatus placement/removal |

| Accommodates complex setups | Ideal for intricate experiments and custom reactors |

| Rapid heating and cooling | Faster cycle times and phase transition studies |

| Precise temperature control | Reliable for materials testing and synthesis |

| Versatile applications | Suitable for R&D, materials science, and gas processing |

Ready to elevate your lab's capabilities with a versatile split tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether for research or industrial processes. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency