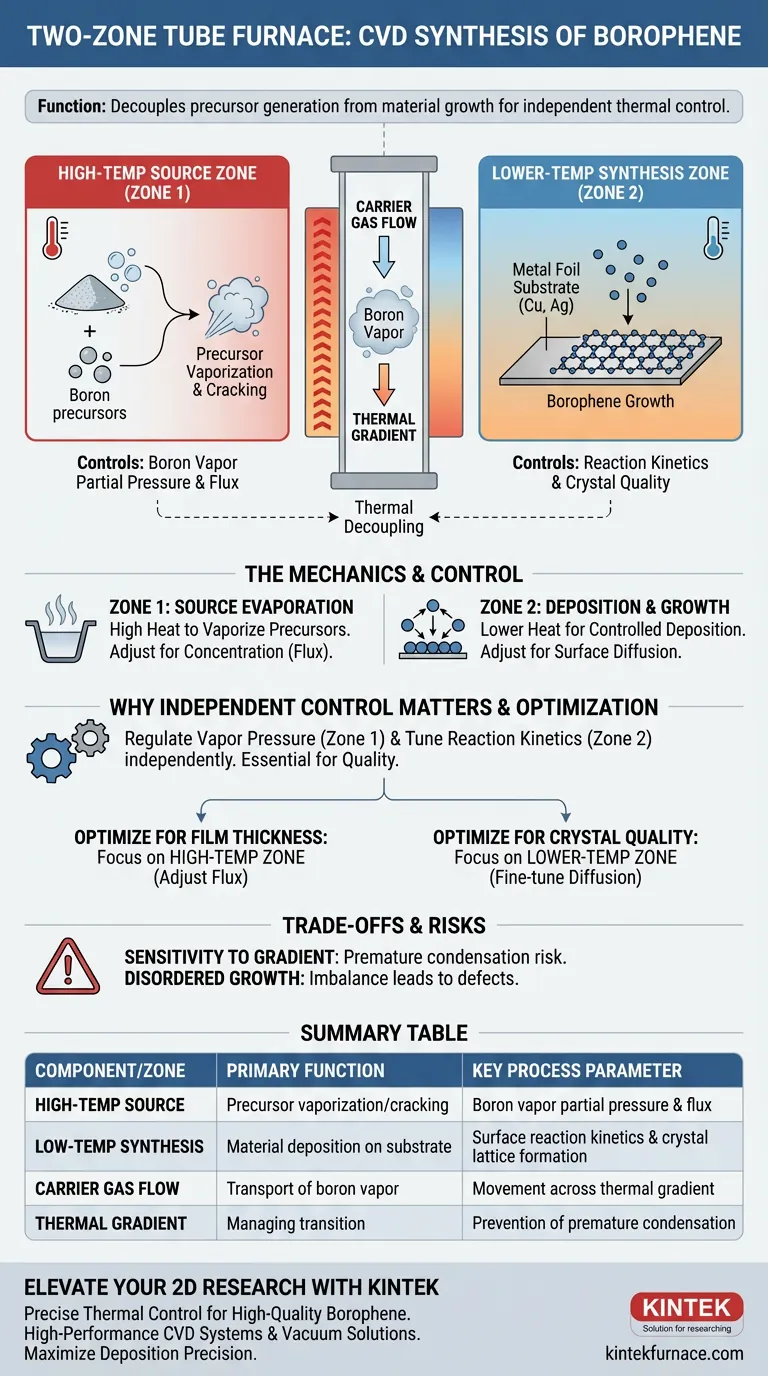

A two-zone tube furnace functions by creating two distinct thermal environments within a single reaction chamber, effectively decoupling the generation of boron vapor from the actual growth of the material. In the Chemical Vapor Deposition (CVD) of Borophene, the upstream high-temperature zone is responsible for vaporizing or cracking boron precursors, while the downstream lower-temperature zone facilitates the controlled deposition and crystallization of boron atoms onto a metal substrate.

The core advantage of this system is independent process control. By separating the source evaporation temperature from the substrate growth temperature, you can precisely tune the vapor partial pressure and reaction kinetics, which are the deciding factors in Borophene quality and layer thickness.

The Mechanics of Dual-Zone Synthesis

The High-Temperature Source Zone

The first zone is the evaporation sector. Its primary function is to subject boron precursors—such as boron powder mixed with boron oxide, or gases like diborane—to high heat.

This intense thermal energy causes the precursors to evaporate or crack, generating the necessary boron vapor. By adjusting the temperature here, you directly control the concentration (flux) of boron atoms released into the system.

The Lower-Temperature Synthesis Zone

The second zone is the deposition sector, situated downstream from the source. This zone contains the growth substrate, typically a metal foil such as copper or silver.

This zone is maintained at a lower temperature relative to the source zone. This temperature is carefully selected to optimize the surface diffusion and reaction of boron atoms on the metal lattice, allowing them to arrange into the 2D Borophene structure.

The Role of Carrier Gas

While the furnace provides the heat, a carrier gas facilitates transport. The gas moves the boron vapors generated in the high-temperature zone through the furnace chamber.

The vapors travel down the temperature gradient to the cooler substrate zone, where controlled condensation and crystallization occur.

Why Independent Control Matters

Regulating Vapor Partial Pressure

The temperature of the source zone dictates the vapor partial pressure. This determines how much boron is available in the atmosphere surrounding the substrate.

If the source temperature is too low, growth is starved; if too high, excessive atomic concentration can lead to uncontrolled clumping rather than 2D growth.

Tuning Reaction Kinetics

The temperature of the substrate zone dictates reaction kinetics. This controls how fast the boron atoms move and settle once they reach the metal foil.

Precise thermal regulation here ensures the atoms have enough energy to diffuse into a high-quality crystal lattice, but not so much that they desorb or form unwanted bulk structures.

Understanding the Trade-offs

Sensitivity to Gradient

The success of the synthesis relies heavily on the spatial temperature gradient between the two zones. If the transition between the high-heat source and the cooler substrate is not managed correctly, precursors may condense prematurely on the tube walls before reaching the substrate.

Risk of Disordered Growth

While dual zones offer control, they introduce complexity. An imbalance between the precursor supply (Zone 1) and the diffusion rate (Zone 2) can lead to disordered grain growth.

As noted in vacuum systems, excessive atomic concentrations caused by improper pressure or temperature settings can prevent the formation of large-area, single-crystal phases.

Making the Right Choice for Your Goal

To optimize your Borophene synthesis, you must tune the two zones based on your specific morphological requirements.

- If your primary focus is Film Thickness (Layer Count): Focus on the High-Temperature Zone. Adjusting the source temperature will increase or decrease the flux of boron vapor, directly impacting how many layers are deposited.

- If your primary focus is Crystal Quality (Single-Phase): Focus on the Lower-Temperature Zone. Fine-tuning the substrate temperature ensures optimal surface diffusion, allowing atoms to arrange into a large-area, ordered crystal lattice.

Success in Borophene CVD relies not just on heating, but on the precise thermal decoupling of precursor supply from material growth.

Summary Table:

| Component/Zone | Primary Function | Key Process Parameter Controlled |

|---|---|---|

| High-Temp Source Zone | Precursor vaporization/cracking | Boron vapor partial pressure & flux |

| Low-Temp Synthesis Zone | Material deposition on substrate | Surface reaction kinetics & crystal lattice formation |

| Carrier Gas Flow | Transport of boron vapor | Movement of precursors across the thermal gradient |

| Thermal Gradient | Managing transition between zones | Prevention of premature precursor condensation |

Elevate Your 2D Material Research with KINTEK

Precise thermal control is the difference between disordered growth and high-quality single-phase Borophene. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Two-Zone Tube Furnaces, CVD systems, and Vacuum solutions specifically engineered to decouple complex reaction variables.

Whether you require customizable heating lengths or advanced gas delivery systems, our lab furnaces are designed to meet your unique synthesis needs. Maximize your deposition precision today—Contact KINTEK for a Consultation.

Visual Guide

References

- Gourang Hari Gupta, Suveen Kumar. Borophene nanomaterials: synthesis and applications in biosensors. DOI: 10.1039/d3ma00829k

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the primary function of a high-temperature tube furnace in HELMA synthesis? Achieve 1500°C Precision

- What are the main advantages of using a tube furnace in industrial and laboratory settings? Achieve Precise Temperature and Atmosphere Control

- Why is it necessary to integrate aluminum alloy plates into split tube furnace covers? Ensure Safety and Longevity

- How do tube furnaces contribute to transport reactions and crystal production? Master High-Purity Synthesis with Precision Control

- What role does a tube furnace play in the pyrolysis of covalent triazine frameworks? Optimize Your Carbon Synthesis

- How do the heating elements in a tube furnace function? Uncover Key Insights for Precise Heating

- What are the configuration options available for split tube furnaces? Customize for Precise Thermal and Atmospheric Control

- What role does a tube high-temperature furnace play in the synthesis of nano carbon spheres? Unlock sp2 Hybridization