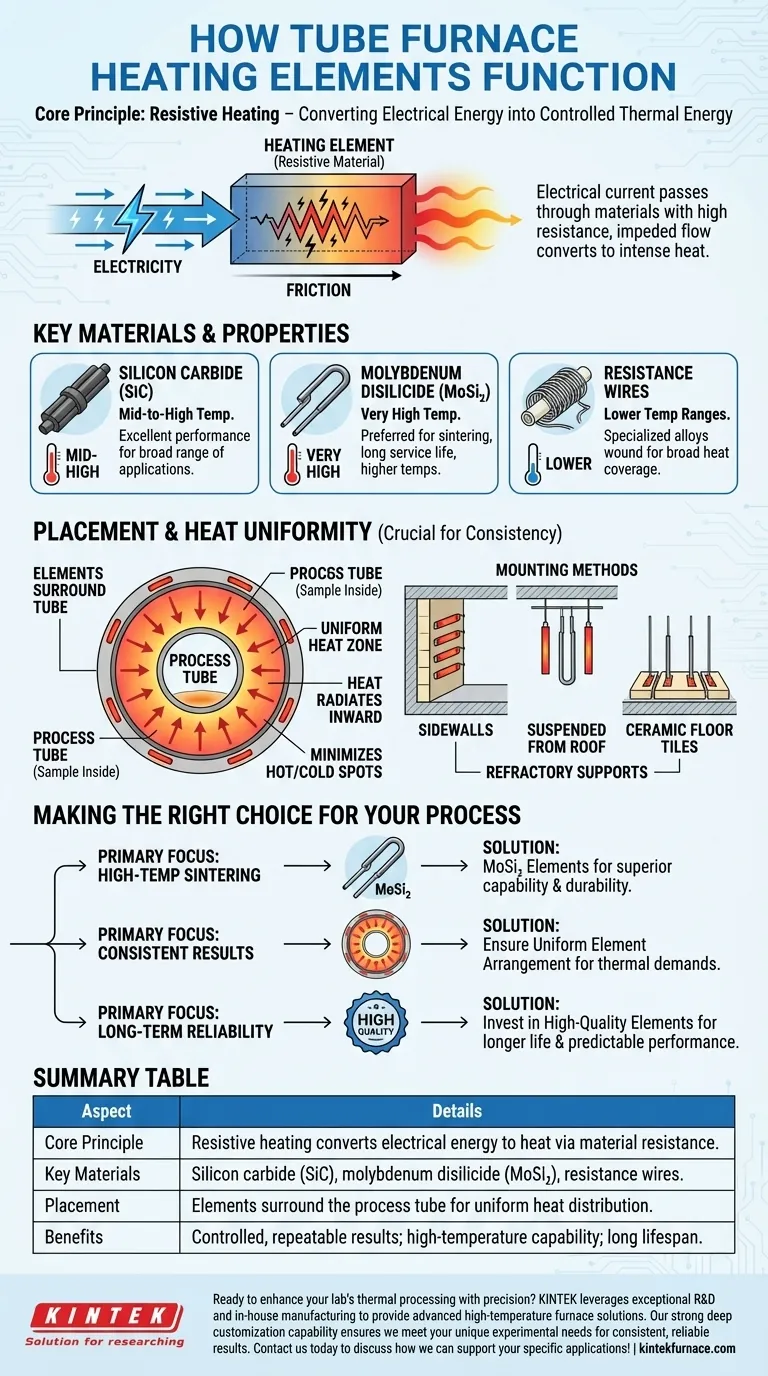

At their core, the heating elements in a tube furnace function by converting electrical energy into heat through a process called resistive heating. When an electrical current is passed through these specialized components, their inherent resistance causes them to heat up intensely, radiating thermal energy into the furnace chamber.

The function of a heating element is not merely to generate heat, but to do so in a controlled and uniform manner. The material, quality, and physical arrangement of these elements are what ultimately determine a furnace's ability to achieve precise, repeatable results.

The Core Principle: Resistive Heating

Converting Electricity into Heat

Heating elements work on the simple principle of electrical resistance. They are made from materials that impede the flow of electricity.

As current is forced through this resistance, the electrical energy is converted directly into thermal energy, or heat. This is the same fundamental concept that makes an electric stovetop or a toaster work.

The Role of the Element Material

The choice of material is critical. Different materials offer different levels of resistance, maximum operating temperatures, and lifespans.

Common high-performance materials like silicon carbide or molybdenum disilicide are chosen for their ability to withstand extremely high temperatures and repeated heating and cooling cycles.

Element Placement and Heat Uniformity

Why Uniformity Is Essential

For scientific and industrial processes, it is crucial that the sample inside the tube is heated evenly from all sides. Uneven heating can ruin experiments or create defects in materials.

The goal of element placement is to create a zone of consistent, uniform temperature within the furnace tube.

Surrounding the Process Tube

To achieve this uniformity, heating elements are almost always distributed around the circumference of the process tube.

This arrangement ensures that heat radiates inward from multiple directions, minimizing hot spots and cold spots on the sample being processed.

Common Mounting Methods

Elements must be held securely in place. They can be mounted to the furnace sidewalls, suspended from the roof, or set into pre-formed ceramic tiles on the furnace floor.

These supports are made from refractory ceramic or specialized alloys that can withstand the furnace's extreme operating temperatures without degrading.

Understanding the Key Materials

Silicon Carbide (SiC)

Silicon Carbide is a robust and widely used material for heating elements. It provides excellent performance for a broad range of mid-to-high temperature applications.

Molybdenum Disilicide (MoSi₂)

For very high-temperature processes, such as sintering advanced ceramics, molybdenum disilicide elements are often the preferred choice.

These elements can reach higher temperatures than SiC and offer a long service life, contributing to consistent furnace performance over time.

Resistance Wires

In some furnace designs, particularly for lower temperature ranges, elements are formed from specialized resistance wire alloys.

These wires are typically wound around a ceramic support structure to provide broad heat coverage within the chamber.

Making the Right Choice for Your Process

Understanding the heating elements helps you select the right equipment for your specific needs.

- If your primary focus is high-temperature sintering: Seek out furnaces with molybdenum disilicide (MoSi₂) elements for their superior temperature capability and durability.

- If your primary focus is consistent, repeatable results: Pay close attention to how elements are arranged to ensure the furnace provides the thermal uniformity your process demands.

- If your primary focus is long-term reliability: Investing in a furnace with high-quality elements from a reputable manufacturer will lead to a longer service life and more predictable performance.

Ultimately, a deep understanding of your furnace's heating system empowers you to control your process with precision and confidence.

Summary Table:

| Aspect | Details |

|---|---|

| Core Principle | Resistive heating converts electrical energy to heat via material resistance. |

| Key Materials | Silicon carbide (SiC), molybdenum disilicide (MoSi₂), resistance wires. |

| Placement | Elements surround the process tube for uniform heat distribution. |

| Benefits | Controlled, repeatable results; high-temperature capability; long lifespan. |

Ready to enhance your lab's thermal processing with precision? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for consistent, reliable results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency