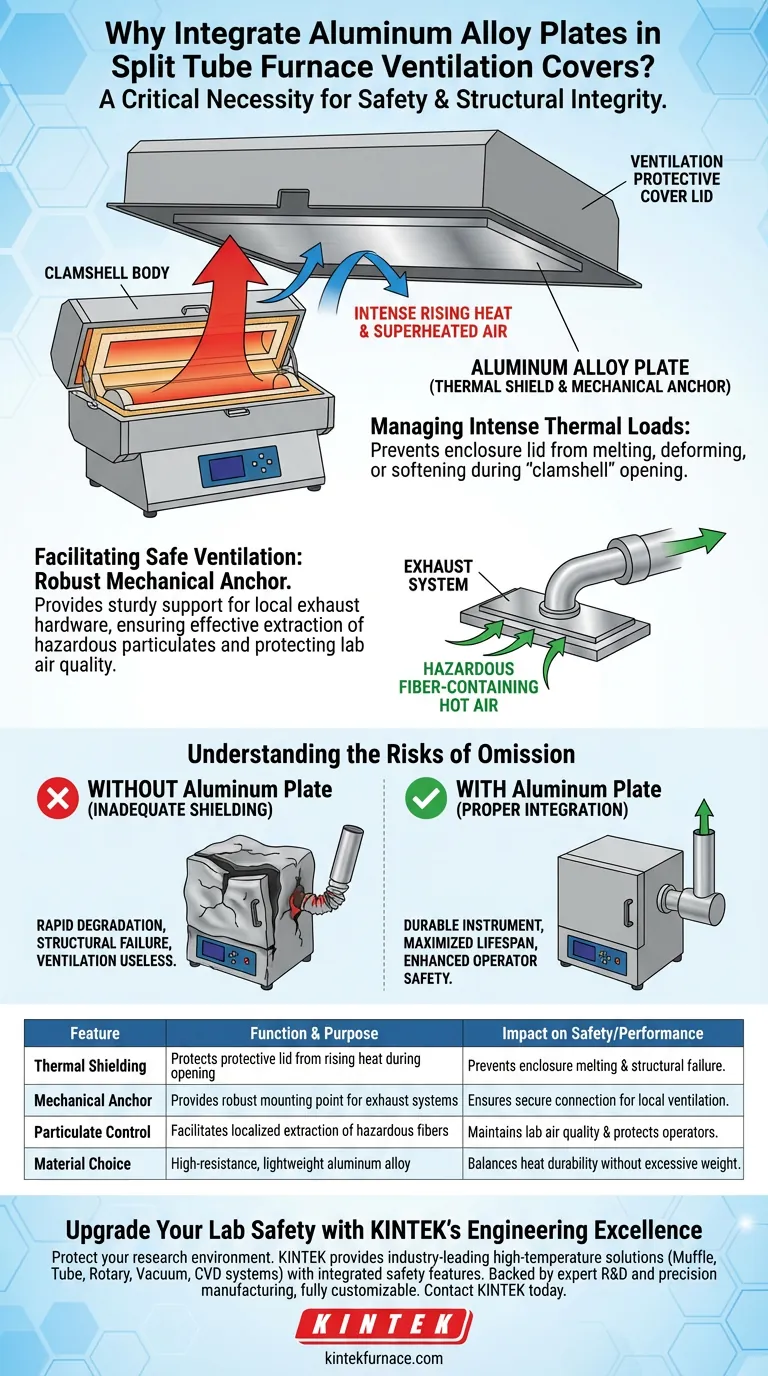

Integrating aluminum alloy plates is a critical necessity for preserving the structural integrity and safety of split tube furnaces. These components serve a dual purpose: they act as a thermal shield to prevent the rising heat from melting or deforming the protective enclosure lid when the furnace is opened, and they provide a robust mechanical anchor for connecting exhaust systems to remove hazardous hot air.

Core Takeaway The integration of aluminum alloy plates is not an optional feature but a fundamental safety requirement. It safeguards the equipment against catastrophic thermal deformation during "clamshell" operation and enables the effective, localized extraction of fiber-containing particulates.

Managing Intense Thermal Loads

The Challenge of Clamshell Operation

Split tube furnaces are designed to open in a clamshell manner, which exposes the internal insulation layer directly to the environment. When the furnace body opens while hot, a massive column of superheated air immediately rises upward.

Preventing Enclosure Failure

Without a dedicated thermal barrier, this rising heat strikes the underside of the ventilation protective cover. The aluminum alloy plate acts as a critical heat shield in this specific zone. It prevents the protective enclosure lid from softening, deforming, or melting under the intense thermal stress.

Facilitating Safe Ventilation

Providing a Structural Anchor

Effective ventilation requires a secure physical connection between the furnace and the exhaust system. The aluminum plate serves as a sturdy mechanical support point. This allows for the reliable attachment of local exhaust hardware, which lightweight plastic or thin sheet metal enclosures might not support effectively.

Controlling Hazardous Particulates

The insulation materials inside high-temperature furnaces can release fibers during operation. By anchoring the exhaust system effectively, the aluminum plate ensures that this fiber-containing hot air is captured at the source. This prevents hazardous particulates from entering the laboratory or workspace environment.

Understanding the Risks of Omission

The Consequence of Inadequate Shielding

It is a common misconception that the outer shell of a furnace is inherently capable of withstanding internal operating temperatures. Omitting these aluminum reinforcements leads to rapid degradation of the housing. This results not only in cosmetic damage but in structural failure that can render the ventilation system useless.

Balancing Weight and Durability

While adding metal plates increases the weight of the protective cover, this trade-off is unavoidable for safety. The aluminum alloy offers a specific balance, providing high thermal resistance and mechanical strength without adding the excessive weight associated with denser metals like steel.

Ensuring System Integrity

To maximize the lifespan of your equipment and the safety of your operators, consider the following:

- If your primary focus is Equipment Longevity: Ensure the aluminum plates are inspected regularly for signs of thermal stress, as they sacrifice themselves to save the outer enclosure.

- If your primary focus is Operator Safety: Verify that the local exhaust system is securely bolted to the aluminum support point to guarantee the removal of airborne fibers.

Properly integrated thermal shielding is the difference between a durable, safe instrument and a potential laboratory hazard.

Summary Table:

| Feature | Function & Purpose | Impact on Safety/Performance |

|---|---|---|

| Thermal Shielding | Protects the protective lid from rising heat during clamshell opening | Prevents enclosure melting, softening, and structural failure |

| Mechanical Anchor | Provides a robust mounting point for exhaust systems | Ensures secure connection for local ventilation hardware |

| Particulate Control | Facilitates localized extraction of hazardous fibers | Maintains laboratory air quality and protects operators |

| Material Choice | High-resistance, lightweight aluminum alloy | Balances heat durability without excessive weight gain |

Upgrade Your Lab Safety with KINTEK’s Engineering Excellence

Protect your research environment from hazardous thermal stress and particulates. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all meticulously designed with integrated safety features like thermal shielding.

Backed by expert R&D and precision manufacturing, our lab furnaces are fully customizable to meet your specific technical requirements. Contact KINTEK today to discuss how our robust furnace designs can enhance your lab's safety and equipment longevity.

Visual Guide

References

- Nina Z. Janković, Desirée L. Plata. Particles in a box: novel design and evaluation of an adaptable engineering control enclosure for a common split tube furnace to eliminate occupational exposure to refractory ceramic insulation fibers. DOI: 10.1039/d3en00041a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role do industrial tube furnaces play in the oxidation of NiCrAl alloys? Precise Stability for Reliable Data

- What role does a high-purity quartz tube furnace play in graphene growth? Achieve Conformal Optical Resonator Coating

- How is the atmosphere controlled in a vacuum tube furnace? Achieve Precise Gas Environments for Your Experiments

- Why is a Quartz Tube Furnace with Gas Flow Control Required for Iodine Doping? Precision Single-Atom Catalyst Synthesis

- What role does a laboratory tube furnace serve during Si/Al2O3/RGO synthesis? Precise Thermal Reduction & Bonding

- What are the maintenance requirements for a horizontal electric furnace? Ensure Peak Performance and Longevity

- What kind of experimental environment does a high vacuum tube furnace provide for high-performance ceramic preparation?

- What role does a high-temperature tube furnace play in the preparation of cellulose-based carbon nanofibers?