A high vacuum tube furnace establishes an ultra-clean, low-oxygen thermal environment essential for advanced material processing. By utilizing high-precision vacuum systems and specialized sealing designs, it virtually eliminates atmospheric gases to protect sensitive raw materials from degradation during heat treatment.

The core value of this environment lies in its ability to decouple heat from oxidation. It provides the strict atmospheric control necessary to synthesize high-purity non-oxide ceramics—such as carbides and nitrides—ensuring the final material retains a precise chemical composition and high structural density.

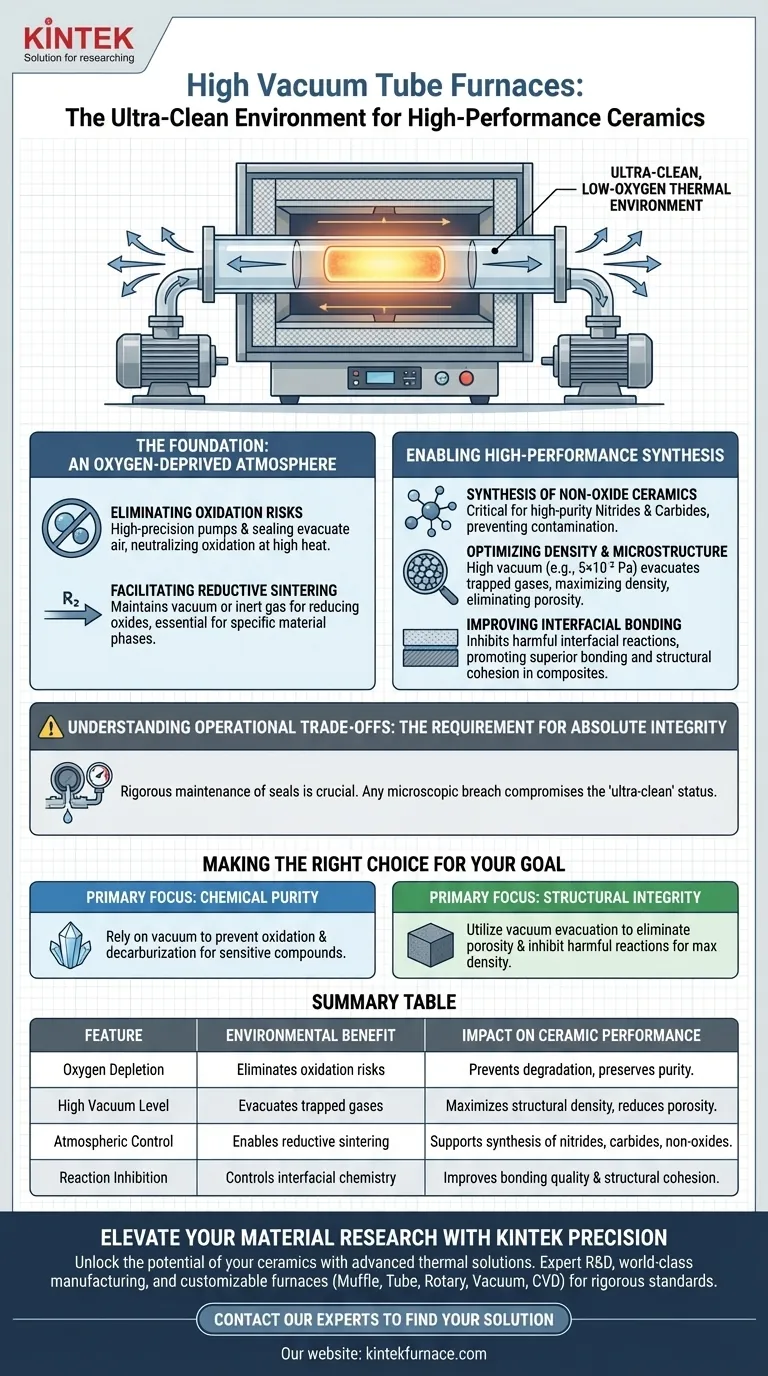

The Foundation: An Oxygen-Deprived Atmosphere

Eliminating Oxidation Risks

The primary function of a high vacuum tube furnace is to create a space with extremely low oxygen content.

High-precision vacuum pumps and advanced sealing mechanisms work together to evacuate atmospheric air. This prevents oxygen from interacting with sensitive raw materials at high temperatures, effectively neutralizing the risk of oxidation that would otherwise degrade the material's properties.

Facilitating Reductive Sintering

Beyond simple protection, this environment actively supports reductive sintering processes.

By maintaining a vacuum or introducing controlled inert gases, the furnace allows for chemical reactions that reduce oxides rather than create them. This is a prerequisite for achieving specific material phases that cannot exist in an oxygen-rich environment.

Enabling High-Performance Synthesis

Synthesis of Non-Oxide Ceramics

The vacuum environment is critical for the production of high-purity nitrides and carbides.

These materials are highly sensitive to impurities found in standard air. The furnace ensures that the chemical composition remains precise, allowing for the successful synthesis of these advanced ceramic compounds without contamination.

Optimizing Density and Microstructure

A high vacuum (e.g., 5×10⁻² Pa) does more than manage chemistry; it improves the physical structure of the material.

The vacuum effectively evacuates trapped gases from the interstices of powder materials. Removing these gases is decisive for maximizing material density, as trapped gas pockets can lead to porosity and structural weakness in the final product.

Improving Interfacial Bonding

In composite materials, the interface between different components is often the weak point.

The vacuum atmosphere helps inhibit the formation of harmful interfacial reaction products, such as excessive aluminum carbide in certain alloy matrices. By controlling these reactions, the furnace promotes superior interfacial bonding quality, resulting in a stronger, more cohesive material.

Understanding the Operational Trade-offs

The Requirement for Absolute Integrity

The benefits of a high vacuum environment rely entirely on the integrity of the sealing designs.

Any breach or leak, however microscopic, compromises the "ultra-clean" status of the chamber. This requires rigorous maintenance of seals and constant monitoring of vacuum levels to prevent inadvertent contamination (oxidation or decarburization) during the heating cycle.

Making the Right Choice for Your Goal

To maximize the utility of a high vacuum tube furnace, align the environmental capabilities with your specific processing targets:

- If your primary focus is Chemical Purity: Rely on the vacuum's ability to prevent oxidation and decarburization to synthesize sensitive compounds like nitrides and carbides.

- If your primary focus is Structural Integrity: Utilize the vacuum's gas evacuation capabilities to eliminate porosity and inhibit harmful interfacial reactions for maximum density.

Mastering this environment is the key to transitioning from standard ceramic processing to high-performance material engineering.

Summary Table:

| Feature | Environmental Benefit | Impact on Ceramic Performance |

|---|---|---|

| Oxygen Depletion | Eliminates oxidation risks | Prevents degradation and preserves chemical purity |

| High Vacuum Level | Evacuates trapped gases | Maximizes structural density and reduces porosity |

| Atmospheric Control | Enables reductive sintering | Supports synthesis of nitrides, carbides, and non-oxides |

| Reaction Inhibition | Controls interfacial chemistry | Improves bonding quality and structural cohesion |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your high-performance ceramics with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the most rigorous experimental standards.

Whether you require ultra-clean atmospheric control or specialized high-temperature sintering, our furnaces are fully customizable to suit your unique lab requirements. Ensure the purity, density, and integrity of your materials today.

Contact Our Experts to Find Your Solution

Visual Guide

References

- Dimple Dimple, Priyanka Verma. Visible‐NIR Light‐Driven Hydrogen Evolution from Ammonia Borane Using Defect‐Engineered Pd/WO<sub>3‐x</sub> Catalyst. DOI: 10.1002/cctc.202500795

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why are Tube Furnaces used? Unlock Precision Heating for Your Lab

- Why is a high-precision tube furnace required for PtCln/Fe-N-C catalysts? Ensure Sub-Nanometer Precision

- What role do vacuum tube furnaces play in ceramic and glass manufacturing? Unlock High-Purity, Dense Materials

- How does a vacuum tube furnace contribute to the annealing of FePC amorphous alloys? Precision Microstructural Control

- How does a Tube Furnace ensure structural consistency in Fe/MWCNT synthesis? Expert Control for Composite Quality

- Why is a tube furnace with high-purity Ar protection necessary for LiFePO4 calcination? Ensure Fe2+ Phase Purity

- What environmental conditions does a vacuum tube furnace provide for FTO(p)/ZnS(p) films? High-Purity Post-Treatment

- Why is it necessary to evacuate and seal quartz tubes for NiPS3 crystals? Master CVT Precision & Purity