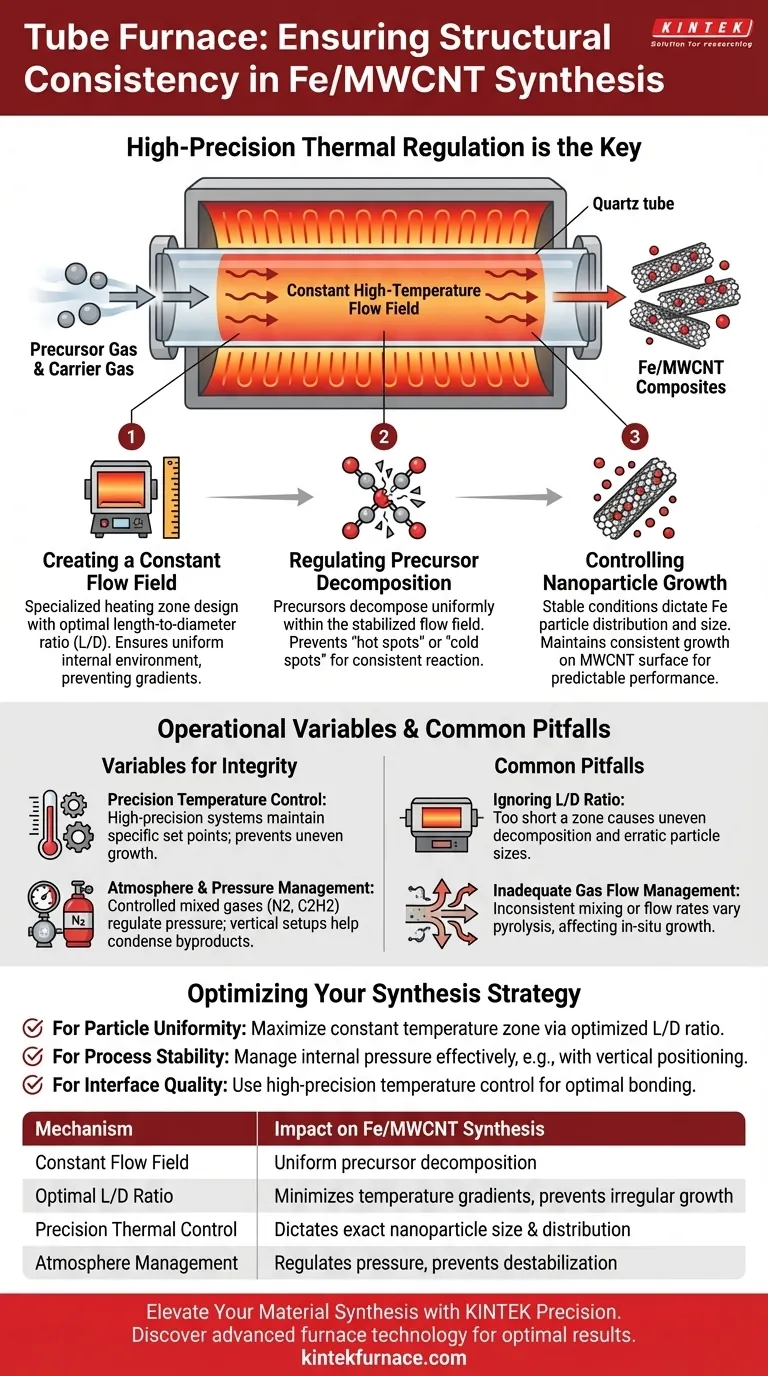

High-precision thermal regulation is the defining factor. A Tube Furnace ensures structural consistency in Iron/Multi-Walled Carbon Nanotube (Fe/MWCNT) composites by maintaining a constant high-temperature flow field. This stability allows reaction precursors to decompose uniformly, directly controlling the size and distribution of iron nanoparticles.

The synthesis of Fe/MWCNT composites relies on stable thermodynamics to prevent irregular particle growth. By optimizing the heating zone's length-to-diameter ratio and strictly controlling temperature, the tube furnace ensures uniform precursor decomposition and consistent nanoparticle dispersion.

The Mechanics of Structural Consistency

To understand how a Tube Furnace achieves consistency, one must look beyond simple heating. The key lies in how the furnace shapes the thermodynamic environment during the Chemical Vapor Deposition (CVD) process.

Creating a Constant Flow Field

The primary mechanism for consistency is the creation of a constant high-temperature flow field.

This is achieved through a specialized heating zone design.

The furnace utilizes an optimal length-to-diameter ratio to ensure that the internal environment remains uniform throughout the reaction zone.

Regulating Precursor Decomposition

For Fe/MWCNT composites, the reaction precursors must decompose at a specific rate.

The tube furnace ensures that these precursors break down within the stabilized flow field, rather than in areas with fluctuating gradients.

This precise decomposition prevents "hot spots" or "cold spots" that would otherwise alter the chemical reaction.

Controlling Nanoparticle Growth

The ultimate goal of this thermal stability is to dictate how the Iron (Fe) interacts with the Carbon Nanotubes.

Stable conditions are essential for controlling the distribution density of the particles.

Furthermore, they maintain the consistency of the growth size of Fe nanoparticles on the nanotube surface, ensuring the material performs predictably.

Understanding the Operational Variables

While the heating zone geometry is critical, other operational factors provided by the tube furnace setup contribute to the final structural integrity.

Precision Temperature Control

The CVD process is highly sensitive to thermal fluctuations.

Tube furnaces employ high-precision temperature control systems to maintain the specific set point required for the reaction.

Even minor deviations can lead to uneven growth or poor adhesion between the iron and the nanotubes.

Atmosphere and Pressure Management

Consistency also requires a controlled atmosphere, typically involving mixed gases like nitrogen or acetylene.

In specific configurations, such as vertical setups, the tube position creates a temperature gradient that helps regulate internal pressure.

This allows volatile byproducts to condense in cooler zones, preventing overpressure that could destabilize the reaction environment.

Common Pitfalls to Avoid

Even with the correct equipment, structural inconsistencies can occur if the "Deep Need" of thermodynamic stability is ignored.

Ignoring the Length-to-Diameter Ratio

If the heating zone is too short relative to the tube diameter, the constant flow field cannot be established.

This results in a gradient where precursors decompose unevenly, leading to erratic particle sizes.

Inadequate Gas Flow Management

The flow field relies on both heat and gas dynamics.

If the gas atmosphere is not precisely mixed or flow rates are inconsistent, the pyrolysis of carbon sources will vary, affecting the in-situ growth of the composite.

Optimizing Your Synthesis Strategy

To ensure the highest structural consistency in your Fe/MWCNT composites, prioritize the following parameters based on your specific requirements:

- If your primary focus is Particle Uniformity: Ensure your furnace features an optimized heating zone length-to-diameter ratio to maximize the size of the constant temperature zone.

- If your primary focus is Process Stability: Utilize a setup that manages internal pressure effectively, potentially via vertical tube positioning, to handle volatile byproducts safely.

- If your primary focus is Interface Quality: Verify that your temperature control system offers high-precision stability to ensure optimal precursor decomposition and bonding.

Mastering the thermal environment is the only way to turn a volatile chemical reaction into a reproducible manufacturing process.

Summary Table:

| Mechanism | Impact on Fe/MWCNT Synthesis |

|---|---|

| Constant Flow Field | Ensures uniform precursor decomposition across the reaction zone |

| Optimal L/D Ratio | Minimizes temperature gradients to prevent irregular particle growth |

| Precision Thermal Control | Dictates exact nanoparticle size and distribution density |

| Atmosphere Management | Regulates internal pressure and prevents reaction destabilization |

Elevate Your Material Synthesis with KINTEK Precision

Achieving structural consistency in Fe/MWCNT composites requires more than basic heating—it demands the thermodynamic stability only a world-class system can provide. KINTEK offers a comprehensive range of Tube, Vacuum, and CVD systems, along with Muffle and Rotary furnaces, all designed for high-precision lab and industrial applications.

Our expert R&D and manufacturing teams specialize in creating customizable solutions tailored to your unique research needs, ensuring optimal length-to-diameter ratios and superior flow field management.

Ready to master your thermal environment? Contact us today to discover how KINTEK’s advanced furnace technology can optimize your synthesis results!

Visual Guide

References

- Vivek Kumar, Rajnish Dhiman. Fe/MWCNT Nanostructures Synthesized via CVD for Enhanced Electrocatalytic Performance in Zinc‐Air Batteries. DOI: 10.1002/admt.202500539

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What process conditions does a tube furnace provide for Au-Ni-TiO2 nanowires? Master 1000°C VLS Synthesis

- What are the advantages of using a high-temperature tube furnace for rGO sensor fabrication? Precision & Performance

- What is a vertical tube furnace used for in semiconductor manufacturing? Essential for High-Precision Thermal Processing

- What are some thermal processes that tube furnaces are used for? Achieve Precise Heat Treatment with Uniformity

- Why is a high-temperature tube furnace required for Ti3AuC2 annealing? Achieve Perfect Atomic Exchange

- Why do vacuum tube furnaces require strict pressure control for Borophene synthesis? Master Single-Phase Integrity

- What factors should be considered when selecting a tube furnace? Choose the Right Furnace for Your Lab Needs

- How does a fixed-bed reactor system simulate complex flue gas environments? Optimize Mercury Adsorption Testing