Tube furnaces are specialized thermal instruments used for a wide range of high-temperature processes where uniformity and atmospheric control are critical. Key applications include annealing to alter material properties, calcination for thermal decomposition, sintering to fuse powders into a solid mass, material synthesis, and applying coatings through processes like chemical vapor deposition (CVD).

The defining feature of a tube furnace is not just its ability to get hot, but its capacity to create an exceptionally uniform heating zone within a tightly sealed, controlled atmosphere. This makes it indispensable for sensitive processes where contamination or thermal inconsistency would compromise the result.

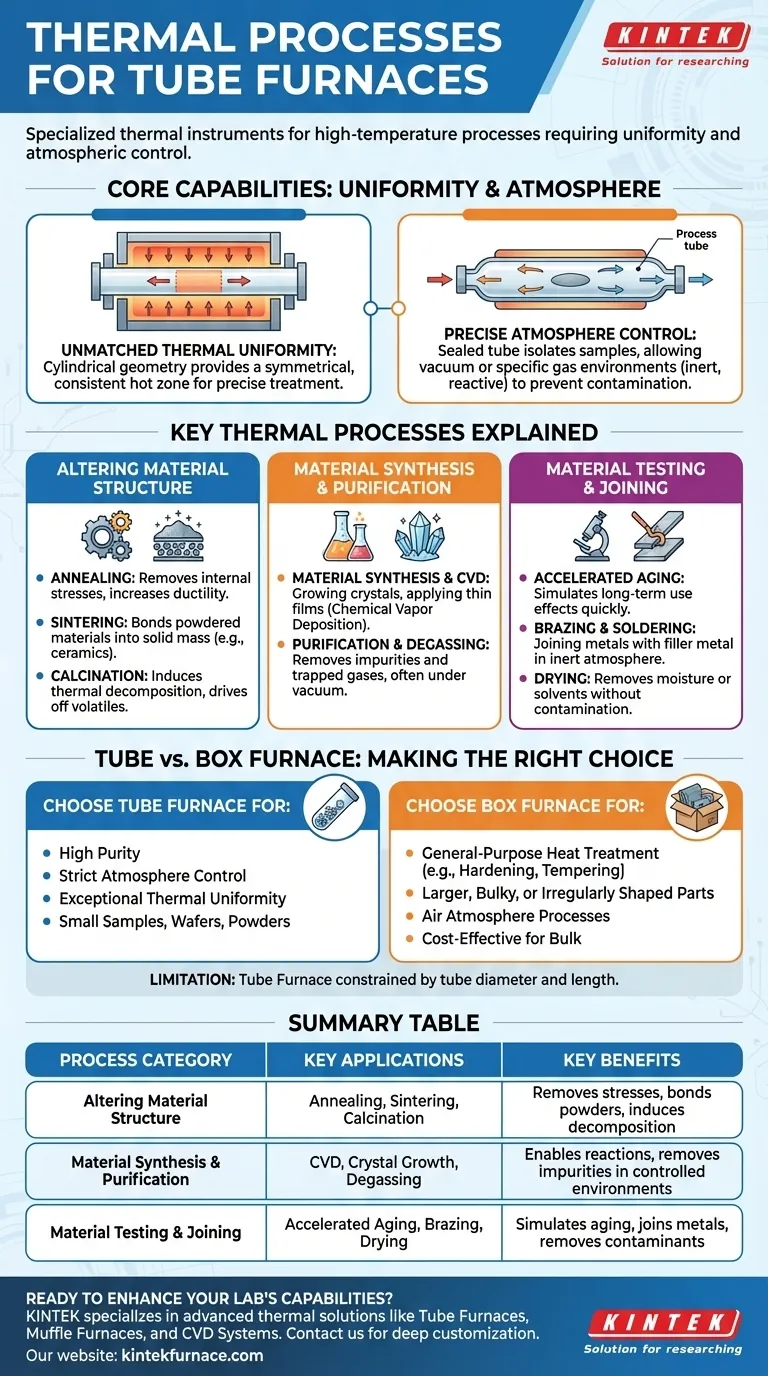

The Core Capabilities: Uniformity and Atmosphere

To understand why tube furnaces are used for specific processes, you must first understand their two primary advantages over other furnace types, like a box furnace.

Unmatched Thermal Uniformity

The cylindrical geometry of a tube furnace allows heating elements to be arranged symmetrically around the central process tube.

This design creates a highly consistent and stable "hot zone" in the center of thefurnace. For small batch production or thermally sensitive materials, this ensures that the entire sample receives the exact same thermal treatment.

Precise Atmosphere Control

The process tube can be easily sealed at both ends, isolating the sample from the outside air.

This isolation is critical. It allows you to either pull a vacuum to remove atmospheric gases (degassing) or introduce a specific inert gas (like Argon) or reactive gas to enable a chemical reaction. This prevents unwanted oxidation and enables processes impossible in an open-air environment.

Key Thermal Processes Explained

The unique capabilities of a tube furnace make it the ideal tool for several categories of thermal processing.

Altering Material Structure

These processes modify the physical properties of a material through carefully controlled heating and cooling cycles.

- Annealing: Heating a material and allowing it to cool slowly in order to remove internal stresses and increase its ductility or softness.

- Sintering: Heating powdered materials below their melting point until their particles bond together, forming a solid or porous mass. This is common in ceramics and powder metallurgy.

- Calcination: Heating a solid material to a high temperature to drive off volatile substances, cause phase transitions, or induce thermal decomposition.

Material Synthesis and Purification

These processes rely on a pristine, controlled environment to create new materials or remove impurities.

- Material Synthesis & CVD: Growing crystals, synthesizing novel compounds, or applying a thin film to a substrate through Chemical Vapor Deposition (CVD), which requires specific precursor gases.

- Purification & Degassing: Heating materials, often under a vacuum, to drive off volatile organic or inorganic impurities and remove gases trapped within the material's structure.

Material Testing and Joining

The controlled environment is also perfect for specialized testing and joining applications.

- Accelerated Aging: Exposing a material to high temperatures to simulate the effects of long-term use in a much shorter time frame.

- Brazing and Soldering: Joining two or more metal items by melting and flowing a filler metal into the joint, where an inert atmosphere prevents oxidation and ensures a clean bond.

- Drying: Removing moisture or solvents from a sample in a highly controlled manner without introducing contaminants.

Understanding the Trade-offs: Tube vs. Box Furnace

A tube furnace is not always the right tool. Choosing correctly depends entirely on the process requirements.

When to Choose a Tube Furnace

A tube furnace is the superior choice when your process demands high purity, strict atmosphere control, or exceptional thermal uniformity. Its design is optimized for these factors above all else.

It is ideal for powders, small components, wafers, or any sample that fits within the confines of the process tube.

When a Box Furnace is a Better Fit

A box furnace, also known as a muffle furnace, is a general-purpose workhorse. It is better suited for processing larger, bulkier, or irregularly shaped parts where a precise atmosphere is not the primary concern.

Processes like hardening, tempering, and stress-relieving are often performed in box furnaces, as they are typically done in air and benefit from the larger chamber volume.

The Limitation of Sample Geometry

The most significant limitation of a tube furnace is its form factor. You are fundamentally constrained by the diameter and length of the process tube, making it unsuitable for large or awkwardly shaped objects.

Making the Right Choice for Your Application

Selecting the correct furnace is a critical decision based on your specific process goals.

- If your primary focus is material purity and atmosphere control: A tube furnace is the necessary tool for processes like high-purity annealing, CVD, or synthesis in a vacuum or inert gas.

- If your primary focus is thermal uniformity for sensitive samples: The consistent hot zone of a tube furnace ensures every part of your sample receives the identical thermal treatment, crucial for research and quality control.

- If your primary focus is processing large or bulky items in air: A box furnace offers greater capacity and is more cost-effective for general heat treatments like tempering or hardening.

Ultimately, understanding these core differences empowers you to select the precise tool for your specific material processing goal.

Summary Table:

| Process Category | Key Applications | Key Benefits |

|---|---|---|

| Altering Material Structure | Annealing, Sintering, Calcination | Removes stresses, bonds powders, induces decomposition |

| Material Synthesis and Purification | CVD, Crystal Growth, Degassing | Enables reactions, removes impurities in controlled environments |

| Material Testing and Joining | Accelerated Aging, Brazing, Drying | Simulates aging, joins metals, removes contaminants |

Ready to enhance your lab's capabilities with tailored thermal solutions? KINTEK specializes in advanced high-temperature furnaces, including Tube Furnaces, Muffle Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs for processes like annealing, sintering, and material synthesis. Contact us today to discuss how our solutions can bring precision and efficiency to your thermal processes!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is uniform heating important in tubular furnaces? Ensure Process Reliability and Predictable Results

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications