The primary advantage of a high-temperature tube furnace in reduced graphene oxide (rGO) sensor fabrication is its ability to provide a strictly controlled thermal and chemical environment that traditional heating methods cannot match. By maintaining a specific atmosphere and precise temperature field, the furnace facilitates the removal of oxygen-containing functional groups to restore conductivity while simultaneously engineering the surface defects necessary for high-performance gas sensing.

A high-temperature tube furnace transforms graphene oxide from a simple material into a functional sensor by balancing two competing needs: restoring electrical pathways and creating carbon vacancy defects that act as active sites for gas adsorption.

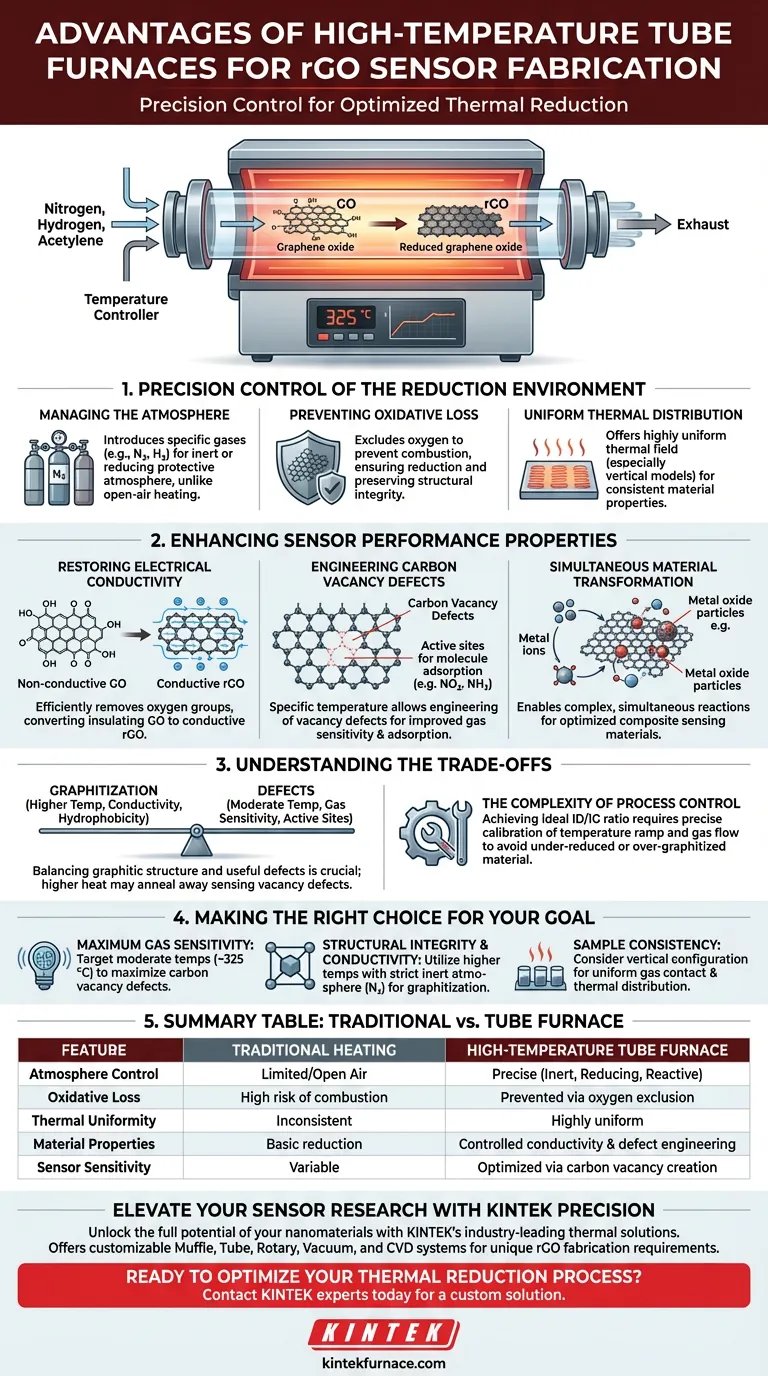

Precision Control of the Reduction Environment

Managing the Atmosphere

Unlike open-air heating, a tube furnace allows for the introduction of specific gas flows, such as nitrogen, hydrogen, or acetylene. This creates an inert or reducing protective atmosphere.

preventing Oxidative Loss

This controlled atmosphere is critical for preventing the oxidative loss of the carbon material itself. By excluding oxygen during the heating process, the furnace ensures the material undergoes reduction rather than combustion, preserving the structural integrity of the sensor.

Uniform Thermal Distribution

Tube furnaces, particularly vertical configurations, offer a highly uniform thermal field. This ensures that every part of the sample—whether powder or thin film—experiences the exact same temperature profile, leading to consistent material properties across the entire batch.

Enhancing Sensor Performance Properties

Restoring Electrical Conductivity

The primary goal of the thermal reduction process is to remove oxygen-containing functional groups from the insulating Graphene Oxide (GO). The tube furnace efficiently drives this reaction, often at specific temperatures like 325 °C, effectively converting GO into conductive rGO.

Engineering Carbon Vacancy Defects

Standard heating restores conductivity, but the tube furnace allows for the specific engineering of carbon vacancy defects. These defects are not errors; they are critical features that significantly improve the sensor's gas sensitivity and adsorption kinetics at room temperature.

Simultaneous Material Transformation

The controlled environment allows for complex, simultaneous reactions. For example, while the GO is being reduced, adsorbed metal ions can be converted into metal oxide particles within the same process step, creating a composite material optimized for sensing.

Understanding the Trade-offs

Balancing Graphitization and Defects

While high heat is necessary, there is a strict trade-off between restoring the graphitic structure and maintaining useful defects. A higher temperature might improve conductivity by graphitizing the material, but it could also anneal away the vacancy defects required for sensing.

The Complexity of Process Control

Achieving the ideal "ID/IG ratio" (the balance between ordered and disordered carbon) requires precise calibration. If the temperature ramp or gas flow is slightly off, you risk creating a material that is either too insulating (under-reduced) or too inert (over-graphitized) to function as a sensitive sensor.

Making the Right Choice for Your Goal

To optimize your rGO sensor fabrication, align your furnace parameters with your specific performance targets:

- If your primary focus is Maximum Gas Sensitivity: Target moderate temperatures (around 325 °C) to maximize carbon vacancy defects, which serve as the active sites for gas adsorption.

- If your primary focus is Structural Integrity and Conductivity: Utilize a higher temperature range with a strict inert atmosphere (Nitrogen) to maximize graphitization and hydrophobicity while preventing material loss.

- If your primary focus is Sample Consistency: Consider a vertical tube furnace configuration to ensure uniform gas contact and thermal distribution across the entire heated zone.

precise control over the thermal and chemical environment is the only way to reliably engineer the specific defect structures that separate a functioning material from a high-performance sensor.

Summary Table:

| Feature | Traditional Heating | High-Temperature Tube Furnace |

|---|---|---|

| Atmosphere Control | Limited/Open Air | Precise (Inert, Reducing, or Reactive) |

| Oxidative Loss | High risk of combustion | Prevented via oxygen exclusion |

| Thermal Uniformity | Inconsistent | Highly uniform (especially in vertical models) |

| Material Properties | Basic reduction | Controlled conductivity & defect engineering |

| Sensor Sensitivity | Variable | Optimized via carbon vacancy creation |

Elevate Your Sensor Research with KINTEK Precision

Unlock the full potential of your nanomaterials with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique rGO fabrication requirements. Whether you need to maximize gas sensitivity through defect engineering or ensure consistent graphitization, our high-temperature furnaces provide the strictly controlled environments your research demands.

Ready to optimize your thermal reduction process? Contact KINTEK experts today for a custom solution

Visual Guide

References

- Tianci Liu, Seong Chan Jun. Hybrid Series of Carbon‐Vacancy Electrodes for Multi Chemical Vapors Diagnosis Using a Residual Multi‐Task Model. DOI: 10.1002/advs.202500412

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What role does a high-temperature tube furnace play in nanoporous carbon synthesis? Essential Activation Stage Insights

- What role does a tube furnace play in the physical synthesis of metal nanoparticles? Master Phase Transformation

- Why is the integration of an axial rotation mechanism significant in tube furnaces? Enhance Experimental Control

- How does the temperature control system work in a multi gradient experimental tube furnace? Master Precise Heat Profiles for Your Lab

- What advantages does a dual-zone tube furnace offer for carbon spheres? Enhanced Control & Superior Morphology

- What is the purpose of using a tube furnace during the reduction phase of graphite flake surface treatment?

- What environmental conditions does a vacuum tube furnace provide for sawdust biochar? Achieve Precise Pyrolysis Control

- What safety measures should be followed when operating a split tube furnace? Ensure Safe and Efficient Lab Operations