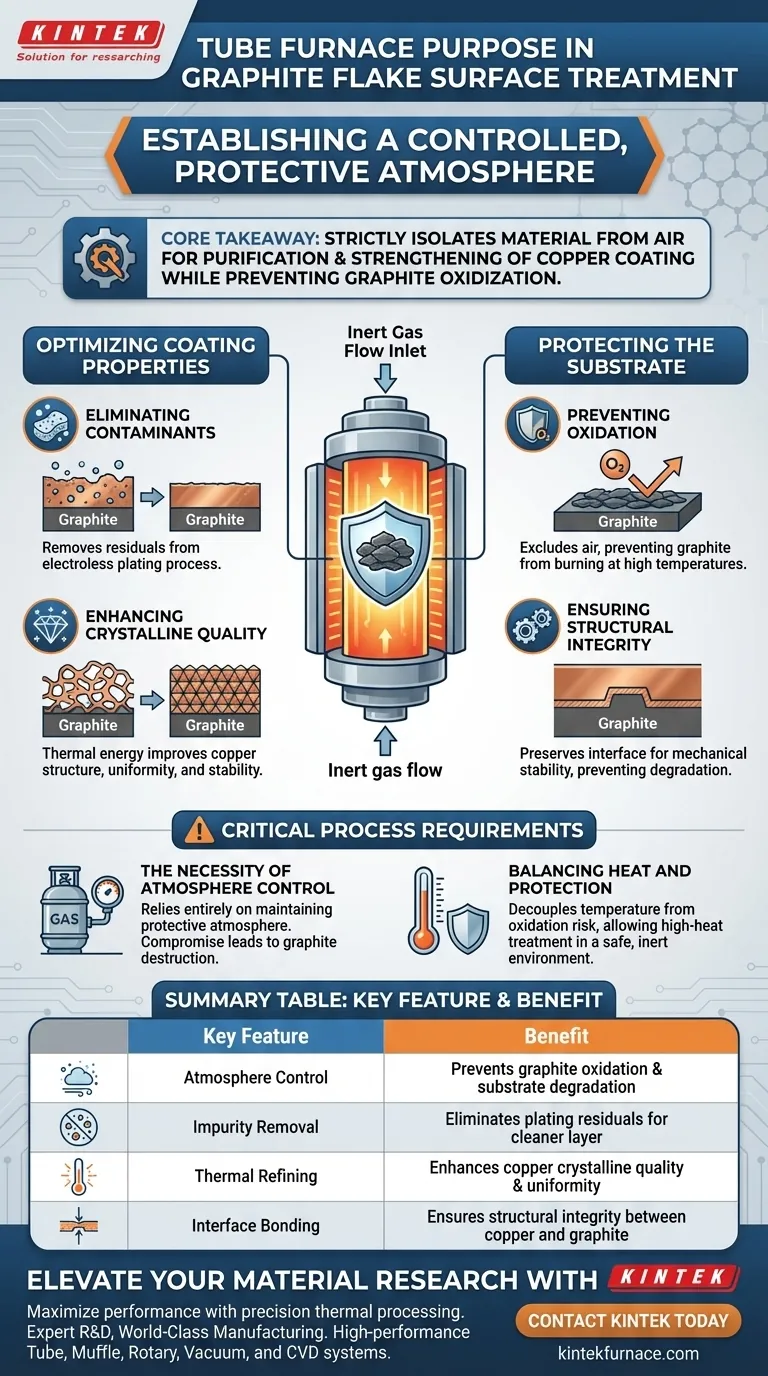

The primary purpose of using a tube furnace in this context is to establish a controlled, protective atmosphere necessary for the high-temperature treatment of graphite flakes. This equipment is critical for removing impurities from the plating layer and significantly improving the crystalline quality of the copper coating without damaging the substrate.

Core Takeaway By strictly isolating the material from air, the tube furnace allows for the purification and strengthening of the copper coating while preventing the graphite from oxidizing, ensuring a durable and structurally sound interface between the two materials.

Optimizing Coating Properties

Eliminating Contaminants

The electroless plating process often leaves behind residuals within the coating. The heat treatment provided by the tube furnace is designed to remove these impurities from the plating layer. This purification step is vital for ensuring the final material performs as intended.

Enhancing Crystalline Quality

Beyond simple cleaning, the thermal energy in the furnace drives a physical change in the coating. The heat treatment improves the crystalline quality of the copper. This structural refinement creates a more uniform and stable metal layer on the graphite flakes.

Protecting the Substrate

Preventing Oxidation

Graphite is highly susceptible to degradation when exposed to oxygen at high temperatures. The tube furnace’s ability to exclude air creates a protective environment. This prevents the graphite flakes from burning or deteriorating during the heating process.

Ensuring Structural Integrity

The interface between the graphite flake and the copper coating is a potential failure point. By preventing oxidation and refining the coating simultaneously, the furnace ensures the structural integrity of this interface. A preserved interface is essential for the mechanical stability of the final composite material.

Critical Process Requirements

The Necessity of Atmosphere Control

The effectiveness of this process relies entirely on the furnace's ability to maintain a protective atmosphere. If the isolation from air is compromised, the high temperatures will destroy the graphite rather than treat it.

Balancing Heat and Protection

Achieving the desired crystalline improvements requires high temperatures. However, these same temperatures pose a risk to the graphite. The tube furnace solves this trade-off by decoupling temperature from oxidation risk, allowing for high-heat treatment in a safe, inert environment.

Achieving Your Material Goals

Depending on your specific requirements for the treated graphite, focus on these aspects of the furnace operation:

- If your primary focus is Conductivity and Performance: Ensure the heat treatment cycle is sufficient to fully improve the crystalline quality of the copper coating.

- If your primary focus is Durability and Lifespan: Prioritize the integrity of the protective atmosphere to strictly prevent any oxidation of the graphite substrate.

The tube furnace is the linchpin that allows you to refine the metallic coating without sacrificing the integrity of the graphite core.

Summary Table:

| Key Feature | Benefit for Graphite Surface Treatment |

|---|---|

| Atmosphere Control | Prevents graphite oxidation and substrate degradation |

| Impurity Removal | Eliminates electroless plating residuals for a cleaner layer |

| Thermal Refining | Enhances copper crystalline quality and coating uniformity |

| Interface Bonding | Ensures structural integrity between the copper and graphite |

Elevate Your Material Research with KINTEK

Maximize the performance of your composite materials with precision thermal processing. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to maintain the strict protective atmospheres required for graphite treatment.

Whether you need to refine metallic coatings or prevent oxidation of sensitive substrates, our lab high-temp furnaces are fully customizable to meet your unique research and production needs. Contact KINTEK today to discover how our specialized equipment can enhance your lab's efficiency and ensure the structural integrity of your materials.

Visual Guide

References

- Hongwei Shi, Zhendong Sun. FINITE ELEMENT SIMULATION OF THERMAL PROPERTIES OF COATED GRAPHITE FLAKE/ALUMINUM MATRIX COMPOSITES. DOI: 10.17222/mit.2025.1380

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What materials are used as sealed containers in a vacuum tube experimental furnace? Optimize Your High-Temp Experiments

- How does a tube resistance furnace contribute to the microstructural control of Ti–Cu alloys? Precision Heat Treatment

- What is the future outlook for three-zone tube furnaces in materials innovation? Unlock Precision for Advanced Materials

- How do vacuum tubes work for dummies? The Simple Analogy to Understand Electronic Control

- What environmental conditions must a high-temperature tube furnace provide for MAX phase sintering? Expert Guidelines

- What role does an industrial-grade high-temperature tube furnace play in the two-step pyrolysis of Fe–Mn–N–C? Optimize Synthesis

- Why is an industrial-grade high-temperature tube furnace used for TiO2NW? Optimize Nanowire Annealing

- What role does a programmable tube furnace play in the remelting of cast iron? Expert Insights on Thermal Precision