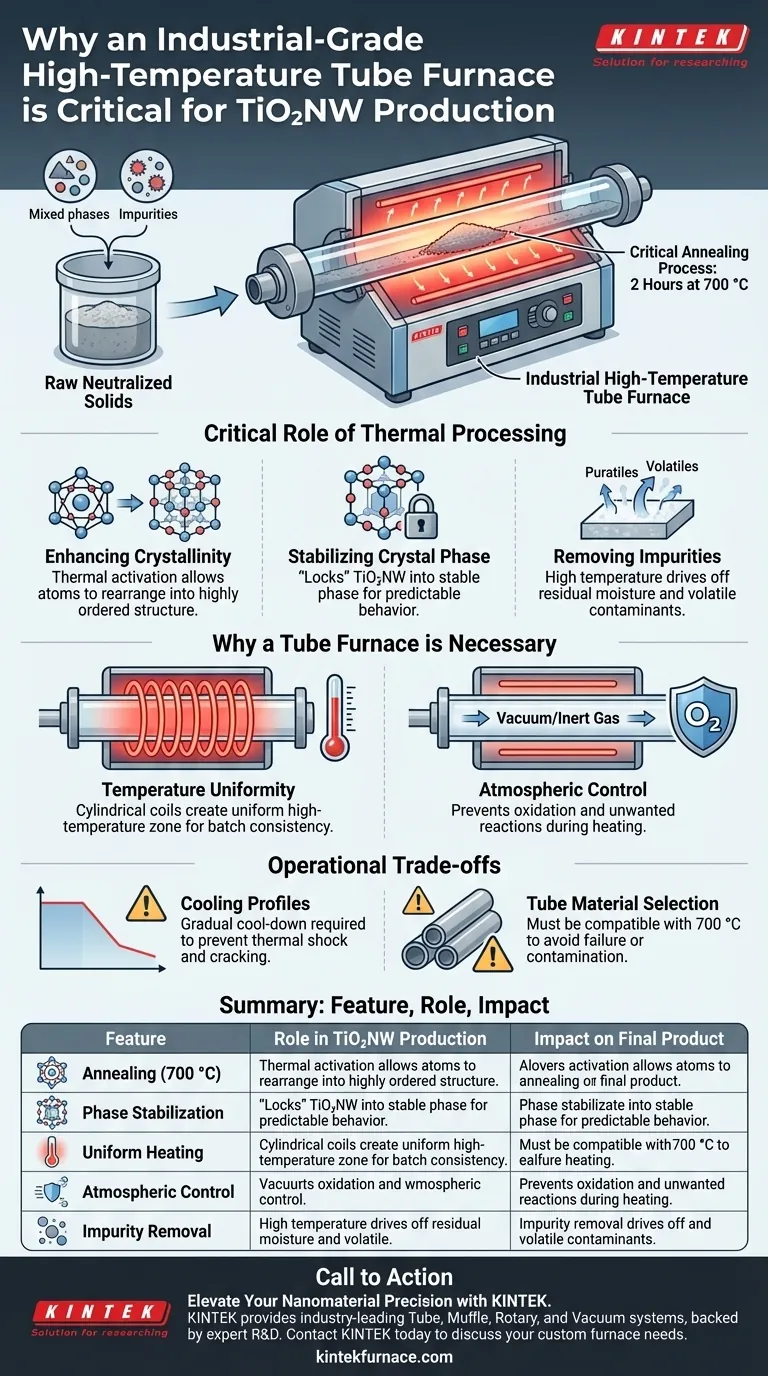

The primary function of an industrial-grade high-temperature tube furnace in this context is to perform a critical annealing process. Specifically, it subjects neutralized solids to a 2-hour heat treatment at 700 °C. This thermal processing is essential for enhancing crystallinity, stabilizing the crystal phase, and removing residual impurities from the Titanium Dioxide Nanowires (TiO2NW).

By providing a highly controlled thermal environment, this furnace transforms raw neutralized solids into structurally stable nanowires capable of withstanding the rigorous conditions found in fuel cell applications.

The Critical Role of Thermal Processing

The final production stage is not merely about drying the material; it is about fundamentally altering its atomic structure to ensure performance.

Enhancing Crystallinity

The heat treatment provides the necessary thermal activation energy. This energy allows the atoms within the solid to rearrange themselves into a highly ordered structure.

Stabilizing the Crystal Phase

Raw synthesized solids often exist in unstable or mixed phases. The 700 °C treatment "locks" the TiO2NW into a stable crystal phase. This stability is required for predictable behavior in chemical reactions.

Removing Impurities

Residual moisture and volatile impurities often remain after the neutralization phase. The high temperature drives these contaminants off, resulting in a purer final product.

Why a Tube Furnace is Necessary

While many heating methods exist, the tube furnace offers specific mechanical advantages required for high-precision nanomaterial synthesis.

Temperature Uniformity

Tube furnaces differ from standard ovens by using cylindrical heating coils. This design creates a zone of high temperature uniformity, ensuring that every part of the sample receives the exact same thermal treatment. This is critical for maintaining phase purity across the entire batch.

Atmospheric Control

These furnaces allow for the introduction of vacuum conditions or inert gases. This protects the sample from unwanted oxidation or reactions with the air during the high-heat phase.

Understanding the Operational Trade-offs

While the tube furnace is the ideal tool for this process, it requires precise operation to avoid damaging the sensitive nanowires.

Cooling Profiles

You cannot simply turn the furnace off and remove the sample immediately. The sample requires a gradual cool-down period. Rapid temperature changes can induce thermal shock, potentially cracking or degrading the nanowire structure.

Tube Material Selection

The physical tube within the furnace must be compatible with the 700 °C operating temperature. Selecting the wrong tube material or size can lead to equipment failure or contamination of the sample.

Making the Right Choice for Your Goal

To maximize the effectiveness of this equipment, tailor your approach to your specific production metric.

- If your primary focus is Phase Purity: Ensure the furnace maintains high temperature uniformity to prevent mixed-phase results across the batch.

- If your primary focus is Structural Stability: Strictly adhere to the 2-hour duration at 700 °C to fully remove volatiles and lock in the crystal structure.

Precision in this final heating stage is the difference between a raw chemical solid and a high-performance fuel cell component.

Summary Table:

| Feature | Role in TiO2NW Production | Impact on Final Product |

|---|---|---|

| Annealing (700 °C) | 2-hour thermal activation | Enhances crystallinity and atomic order |

| Phase Stabilization | Locking crystal structures | Ensures stable performance in fuel cells |

| Uniform Heating | Cylindrical coil design | Maintains phase purity across the entire batch |

| Atmospheric Control | Inert gas/vacuum options | Prevents unwanted oxidation and contamination |

| Impurity Removal | High-heat volatilization | Increases material purity and chemical stability |

Elevate Your Nanomaterial Precision with KINTEK

Achieving the perfect crystal phase in Titanium Dioxide Nanowires requires more than just heat—it requires absolute control. KINTEK provides industry-leading Tube, Muffle, Rotary, and Vacuum systems, all backed by expert R&D and manufacturing to meet your most rigorous lab requirements.

Whether you need custom atmospheric controls or precise cooling profiles to prevent thermal shock, our high-temperature furnaces are designed to transform raw solids into high-performance components. Ready to optimize your synthesis process? Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- Ryo Kato, Atsunori Matsuda. Phosphoric Acid‐Immobilized Polybenzimidazole Hybrid Membranes with TiO<sub>2</sub> Nanowires for High‐Temperature Polymer Electrolyte Membrane Fuel Cells. DOI: 10.1002/celc.202500238

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does high-temperature tube furnace programmed control influence porous carbon? Expert Pore Geometry Insights

- How does a Drop Tube Furnace (DTF) contribute to evaluating the combustion of reducing agents? Optimize Furnace Performance

- What is the process for using a vacuum tube experimental furnace? Master Precise Control for Your Lab

- How does a tube furnace facilitate the carbonization of ZIFs while preventing oxidation? Expert Insights

- What is the academic use of drop tube furnaces? Unlock Precise High-Temp Research for Materials and Energy

- How does a hydrogen reduction environment in an industrial tube furnace facilitate gold-copper alloy microspheres?

- Why choose a vertical tube furnace over a horizontal tube furnace? Achieve Superior Uniformity and Purity

- Why is annealing in a tube furnace essential for rGO-NiO-ZnO-400? Optimize Your Catalyst Synthesis