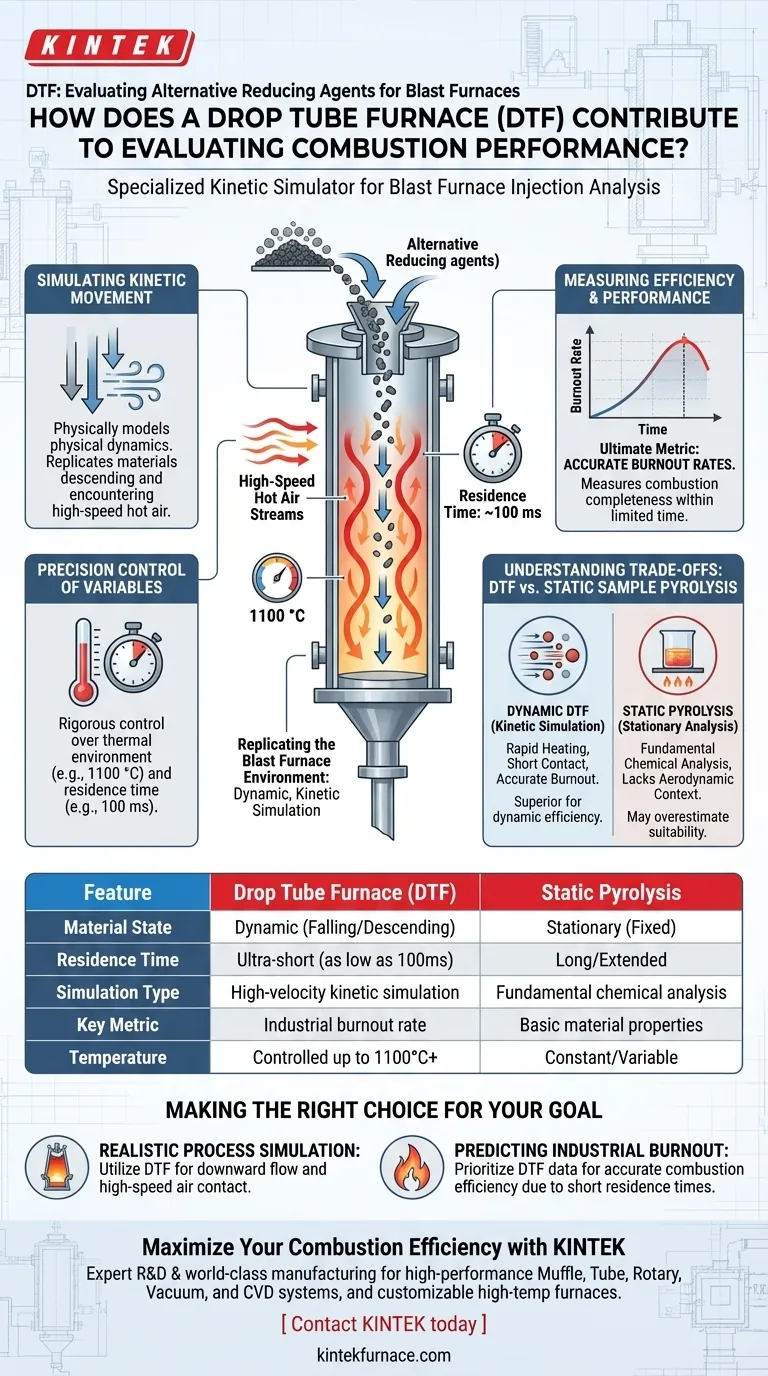

A Drop Tube Furnace (DTF) serves as a specialized kinetic simulator for analyzing how alternative fuels behave during blast furnace injection. It contributes to performance evaluation by physically replicating the specific environment where materials move downward through high-speed hot air streams. By allowing researchers to control temperatures up to 1100 °C and limit residence times to as little as 100 milliseconds, the DTF provides precise measurements of burnout rates under realistic, dynamic conditions.

While static testing methods can identify basic material properties, they often fail to capture the rapid kinetics of industrial injection. The Drop Tube Furnace bridges this gap by mimicking the transient, high-velocity contact between fuel and air, offering a definitive assessment of combustion efficiency.

Replicating the Blast Furnace Environment

Simulating Kinetic Movement

The primary contribution of the DTF is its ability to model the physical dynamics of the blast furnace. Unlike stationary tests, the DTF simulates the specific kinetic process of materials descending.

This setup replicates the critical interaction where falling reducing agents encounter high-speed hot air streams. This dynamic movement is essential for understanding how the fuel will aerodynamically interact with the blast.

Precision Control of Variables

To ensure the data is relevant to industrial operations, the DTF allows for rigorous control over the thermal environment. Researchers can maintain specific preheated furnace temperatures, such as 1100 °C, to match internal furnace conditions.

Furthermore, the descent speed of the material can be adjusted. This control dictates the residence time—the duration the fuel spends inside the hot zone—which can be set to extremely short intervals like 100 ms to test rapid reaction capabilities.

Measuring Efficiency and Performance

Accurate Burnout Rates

The ultimate metric for evaluating alternative reducing agents is the burnout rate. The DTF measures how completely a fuel combusts within the limited time available in the raceway of a blast furnace.

Because the environment is controlled and dynamic, the resulting burnout data is highly indicative of actual performance. It allows operators to screen alternative fuels based on their ability to release energy quickly.

Understanding the Trade-offs

DTF vs. Static Sample Pyrolysis

It is critical to distinguish between dynamic simulations and static analysis. Static sample pyrolysis involves heating a stationary sample, which is useful for fundamental chemical analysis but lacks aerodynamic context.

The DTF is superior for assessing dynamic combustion efficiency. Static methods cannot simulate the rapid heating rates and short contact times characteristic of injection processes, potentially leading to overestimations of a fuel's suitability for high-speed industrial application.

Making the Right Choice for Your Goal

When designing an evaluation protocol for alternative reducing agents, align your testing method with your specific data requirements.

- If your primary focus is realistic process simulation: Utilize the DTF to replicate the downward flow and high-speed air contact inherent to the blast furnace injection zone.

- If your primary focus is predicting industrial burnout: Prioritize DTF data over static pyrolysis results, as the short residence times (e.g., 100 ms) provide a more accurate measure of combustion efficiency.

The Drop Tube Furnace moves beyond theoretical chemistry to provide an operational forecast of how alternative fuels will perform under the rigorous demands of actual production.

Summary Table:

| Feature | Drop Tube Furnace (DTF) | Static Pyrolysis |

|---|---|---|

| Material State | Dynamic (Falling/Descending) | Stationary (Fixed) |

| Residence Time | Ultra-short (as low as 100ms) | Long/Extended |

| Simulation Type | High-velocity kinetic simulation | Fundamental chemical analysis |

| Key Metric | Industrial burnout rate | Basic material properties |

| Temperature | Controlled up to 1100°C+ | Constant/Variable |

Maximize Your Combustion Efficiency with KINTEK

Transitioning to alternative reducing agents requires precise, real-world data to ensure industrial success. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, including specialized high-temp furnaces customizable for your unique simulation needs.

Whether you are analyzing fuel kinetics or scaling blast furnace operations, our technical experts are ready to help you design the perfect thermal solution. Contact KINTEK today to enhance your lab's capabilities and achieve superior material performance.

Visual Guide

References

- Eurig W. Jones, Peter J. Holliman. Pyrolysis-GCMS of Plastic and Paper Waste as Alternative Blast Furnace Reductants. DOI: 10.3390/chemengineering9010015

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is precise atmosphere control necessary in a laboratory tube furnace for Ni-ZIF-8 to Ni-N-C conversion?

- How does a vertical tube gas mixing furnace function in controlling oxygen fugacity? Achieve Precise Magma Simulations

- What materials and processes is an atmosphere tube furnace suitable for? Unlock Precise Heat Treatment Solutions

- What is the function of autoclaves and tube reactors in hydrometallurgical leaching? Unlock Refractory Ore Potential

- What physical conditions does a vertical tube furnace provide for desulfurization experiments? Precision Heat Control

- What role does a high-temperature tube furnace play in flash annealing Mg/SiOx? Precision for Advanced Anode Synthesis

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- What are the maximum temperature capabilities for each zone in a three-zone split tube furnace? Explore Key Ranges and Control