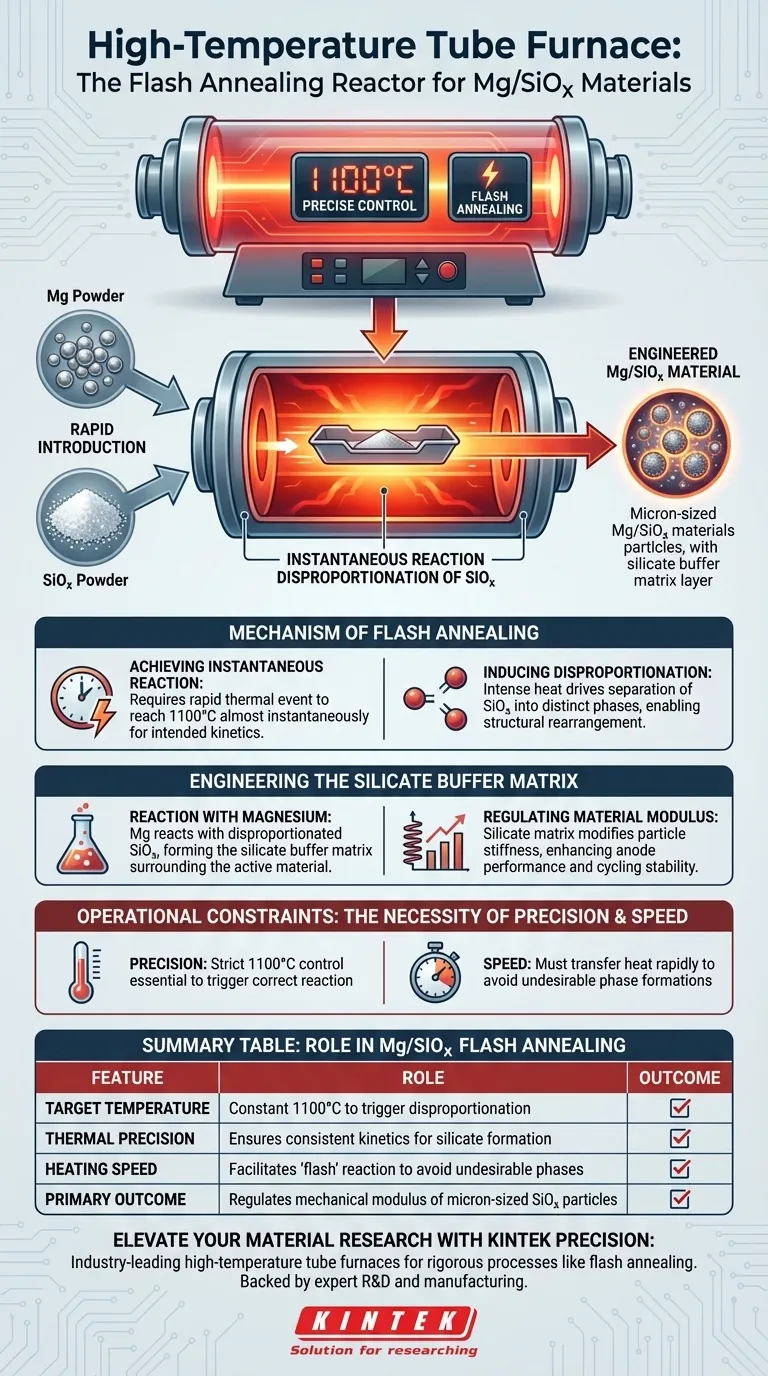

In the preparation of Mg/SiOx materials, the high-temperature tube furnace acts as the critical reactor for executing flash annealing. It provides a precisely controlled thermal environment capable of sustaining 1100 degrees Celsius, which is necessary to trigger the rapid reaction between silicon oxide (SiOx) and magnesium powder.

By maintaining this specific high-temperature condition, the furnace does more than simply heat the materials; it induces an instantaneous disproportionation reaction. This process is fundamental to forming a silicate buffer matrix, which regulates the mechanical modulus of micron-sized SiOx anode materials.

The Mechanism of Flash Annealing

Achieving Instantaneous Reaction

The core function of the tube furnace in this specific protocol is to facilitate a rapid thermal event.

Unlike slow-heating methods, flash annealing requires the materials to reach 1100 degrees Celsius almost instantaneously. The tube furnace must maintain this temperature with high precision to ensure the reaction kinetics proceed as intended.

Inducing Disproportionation

The intense heat provided by the furnace drives the disproportionation of SiOx.

This chemical process involves the separation of the silicon oxide into distinct phases. Without the stable high-temperature environment provided by the furnace, this internal structural rearrangement would not occur efficiently.

Engineering the Silicate Buffer Matrix

Reaction with Magnesium

Within the heated zone of the furnace, the magnesium powder reacts with the disproportionated SiOx.

This reaction is chemically aggressive and relies on the thermal energy supplied by the furnace to reach completion. The result is the formation of a silicate buffer matrix surrounding the silicon active material.

Regulating Material Modulus

The ultimate goal of using the furnace for this process is mechanical regulation.

By successfully forming the silicate buffer matrix, the process modifies the modulus (stiffness) of the micron-sized SiOx particles. This structural change is vital for the material's performance as an anode, likely helping it withstand expansion and contraction during battery cycling.

Understanding the Operational Constraints

The Necessity of Precision

The effectiveness of this process relies entirely on thermal accuracy.

The primary reference emphasizes a precisely controlled environment. Deviations from the 1100-degree target may fail to trigger the specific disproportionation required or result in incomplete reactions between the Mg and SiOx.

The "Flash" Requirement

The nature of "flash" annealing implies speed.

If the furnace cannot transfer heat rapidly enough to the sample—or if the sample is introduced too slowly—the "instantaneous" condition is lost. This could lead to alternative, less desirable phase formations rather than the targeted silicate buffer matrix.

Making the Right Choice for Your Goal

To maximize the quality of your Mg/SiOx anode materials, consider the following regarding your thermal processing equipment:

- If your primary focus is Structural Integrity: Ensure your furnace can maintain exactly 1100°C to guarantee the formation of the silicate buffer matrix, which regulates the material's modulus.

- If your primary focus is Reaction Efficiency: Verify that your loading mechanism and furnace design allow for the rapid ("flash") introduction of heat to induce immediate disproportionation.

The high-temperature tube furnace is the defining tool that transforms raw powders into an engineered, structurally regulated anode material.

Summary Table:

| Feature | Role in Mg/SiOx Flash Annealing |

|---|---|

| Target Temperature | Constant 1100°C to trigger disproportionation |

| Thermal Precision | Ensures consistent reaction kinetics for silicate formation |

| Heating Speed | Facilitates 'flash' reaction to avoid undesirable phases |

| Primary Outcome | Regulates mechanical modulus of micron-sized SiOx particles |

Elevate Your Material Research with KINTEK Precision

Precision is the difference between a successful reaction and a failed experiment. KINTEK provides industry-leading high-temperature tube furnaces specifically engineered for rigorous processes like flash annealing and disproportionation.

Backed by expert R&D and manufacturing, we offer customizable Tube, Muffle, Rotary, Vacuum, and CVD systems designed to maintain the exact thermal environments your Mg/SiOx materials require.

Ready to optimize your lab’s thermal processing? Contact KINTEK experts today to find the perfect customizable solution for your unique high-temperature needs.

Visual Guide

References

- Tuan Lv, Kaifu Huo. Modulus‐Engineered Silicates‐Buffering Matrix for Enhanced Lithium Storage of Micro‐Sized SiO<sub>x</sub> Anodes. DOI: 10.1002/smtd.202500556

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of an industrial tube furnace during the secondary carbonization of biomass? Achieve Precision.

- Why is thermal uniformity important in a drop tube furnace? Ensure Reliable Results and Consistent Processes

- How do tube resistance furnaces or high-temperature box furnaces ensure material quality during the heat treatment of Fe60 alloys?

- How does a benchtop fixed-bed quartz reactor simulate industrial conditions? Evaluate Pt-Ni Catalyst Stability

- What are the advantages of using a condensing tube furnace for magnesium extraction? Achieve High Purity and Efficient Metal Recovery

- What are the key features of temperature control in a vacuum tube furnace? Achieve Precision Heating for Advanced Materials

- What is the role of horizontal furnaces in battery manufacturing? Achieve Precision Thermal Processing for Superior Battery Performance

- What is the purpose of using a high-temperature tube furnace during FePt annealing? Achieve the L1₀ Magnetic Phase