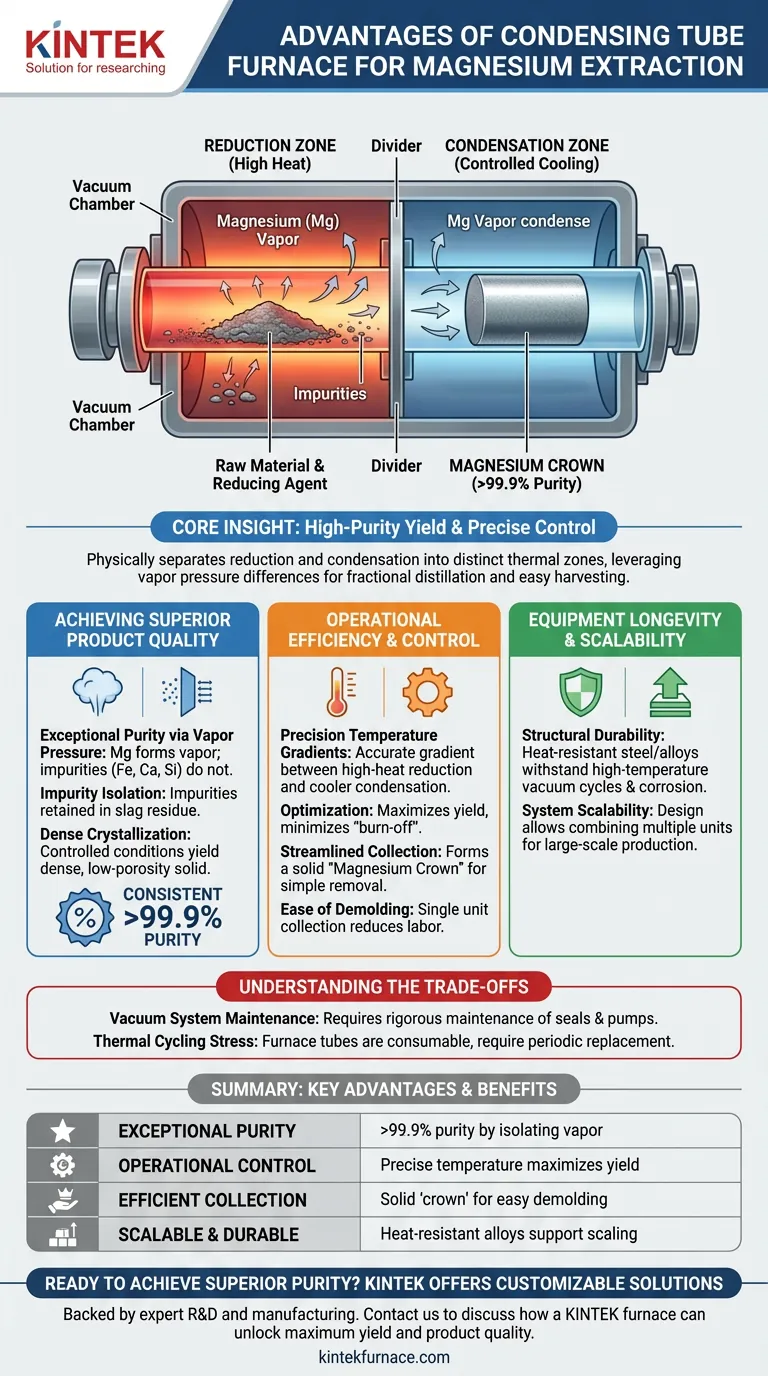

High-purity yield and precise operational control are the defining advantages of using a condensing tube furnace for magnesium extraction. By leveraging vapor pressure differences in a vacuum environment, this equipment isolates magnesium from impurities to achieve purity levels exceeding 99.9%, while simultaneously simplifying the collection of the finished product.

Core Insight: The value of a condensing tube furnace lies in its ability to physically separate the extraction process into distinct thermal zones. This allows for the simultaneous reduction of raw material and the fractional distillation of magnesium vapor, resulting in a dense, high-grade metallic solid that is mechanically easy to harvest.

Achieving Superior Product Quality

Exceptional Purity via Vapor Pressure

The fundamental advantage of this method is its ability to utilize the specific vapor pressure differences between elements. Under controlled vacuum and temperature conditions, magnesium forms a substantial amount of vapor, while impurities like iron, calcium, and silicon do not.

Effective Impurity Isolation

Because the impurities lack the vapor pressure to migrate effectively, they are retained in the slag residue. Consequently, the magnesium that condenses is free from these contaminants, consistently reaching purity levels of 99.9% or higher.

Dense Crystallization Control

Modern furnace designs allow for the management of the crystallization process. By maintaining optimal conditions in the condensation zone, the magnesium vapor solidifies into a dense structure, reducing porosity and improving the quality of the final metal.

Operational Efficiency and Control

Precision Temperature Gradients

These furnaces are equipped with high-quality insulation and advanced temperature control systems. This enables operators to maintain a precise temperature gradient between the high-heat reduction zone and the cooler condensation zone.

Optimization of Reaction and Yield

This thermal precision ensures the reduction reaction proceeds fully without overheating the product. It minimizes "burn-off" (loss of product due to excessive heat or oxidation), thereby maximizing the overall yield of the extraction process.

Streamlined Collection (The "Magnesium Crown")

The design of the condensation structure causes the finished magnesium to form a solid crystallization cylinder, often called a magnesium crown. This specific formation simplifies the post-reaction workflow.

Ease of Demolding

Unlike complex liquid extraction methods, the solid magnesium crown can be easily removed from the furnace tube as a single unit. This significantly reduces the labor and complexity involved in demolding and preparing the metal for remelting.

Equipment Longevity and Scalability

Structural Durability

The reduction tanks (furnace tubes) are constructed from heat-resistant steel or special alloys. These materials are specifically engineered to withstand the rigorous demands of long-term high-temperature vacuum cycles and chemical corrosion.

System Scalability

While individual tube furnaces offer high precision, they are also designed for scalability. Multiple units can often be combined or arranged to meet large-scale production requirements without sacrificing the control inherent in a single-tube design.

Understanding the Trade-offs

While the advantages are significant, it is vital to acknowledge the operational constraints to ensure this solution fits your needs.

Vacuum System Maintenance

The efficiency of this process relies entirely on maintaining a strict vacuum. Leaks or pump failures will immediately degrade product purity and yield, necessitating a rigorous maintenance schedule for seals and vacuum components.

Thermal Cycling Stress

Despite using heat-resistant alloys, the reduction tanks are subjected to extreme thermal cycles and chemical aggression. The furnace tubes are consumable components that will eventually degrade and require replacement to prevent safety hazards or contamination.

Making the Right Choice for Your Goal

The condensing tube furnace is a specialized tool that prioritizes quality and recovery efficiency.

- If your primary focus is Maximum Purity: This is the ideal choice, as the vapor pressure separation method naturally excludes common heavy impurities like iron and silicon.

- If your primary focus is Process Control: The ability to isolate heating zones allows you to fine-tune the reduction rate independently of the condensation rate for consistent results.

- If your primary focus is Ease of Handling: The formation of a solid "magnesium crown" offers the most straightforward physical collection method available for batch extraction.

By aligning the furnace's precise thermal gradients with the physical properties of magnesium, you transform a chaotic extraction process into a controlled, high-yield operation.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Exceptional Purity | Achieves >99.9% purity by isolating magnesium vapor from impurities. |

| Operational Control | Precise temperature gradients maximize yield and minimize product loss. |

| Efficient Collection | Magnesium forms a solid 'crown' for easy, mechanical demolding. |

| Scalable & Durable | Heat-resistant alloy tubes ensure longevity and support production scaling. |

Ready to achieve superior purity and efficiency in your metal extraction processes?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, including customizable condensing tube furnaces designed for high-purity applications like magnesium extraction. Our solutions are engineered to provide the precise thermal control and durability your operations demand.

Contact us today to discuss how a KINTEK furnace can be tailored to your unique needs and unlock maximum yield and product quality.

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is a vertical tube furnace and how does it function? Optimize Material Processing with Precision

- What role does an externally heated Vertical Tube Furnace play in high-temperature molten salt electrolysis systems?

- What is the necessity of using a Tube Furnace for phosphorus-doped carbon nanofiber films? Ensure Anaerobic Precision

- Why is a high-purity argon environment required in a high-temperature tube furnace for ceramic scaffolds?

- Why is a high-temperature tube furnace utilized for the calcination of nano-zinc oxide? Master Microstructure Control

- What is the significance of using a tubular furnace in waste salt pyrolysis research? Precision for High-Fidelity Data

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- How does a high-temperature tube furnace ensure environmental stability for SOEC? Precision Heat & Atmosphere Control