The high-temperature tube furnace serves as a precision instrument for converting zinc hydroxide precursors into chemically active zinc oxide crystals. This thermal treatment is essential because it allows researchers to rigorously control the temperature environment, which directly dictates the grain growth kinetics and surface chemistry required for effective desulfurization.

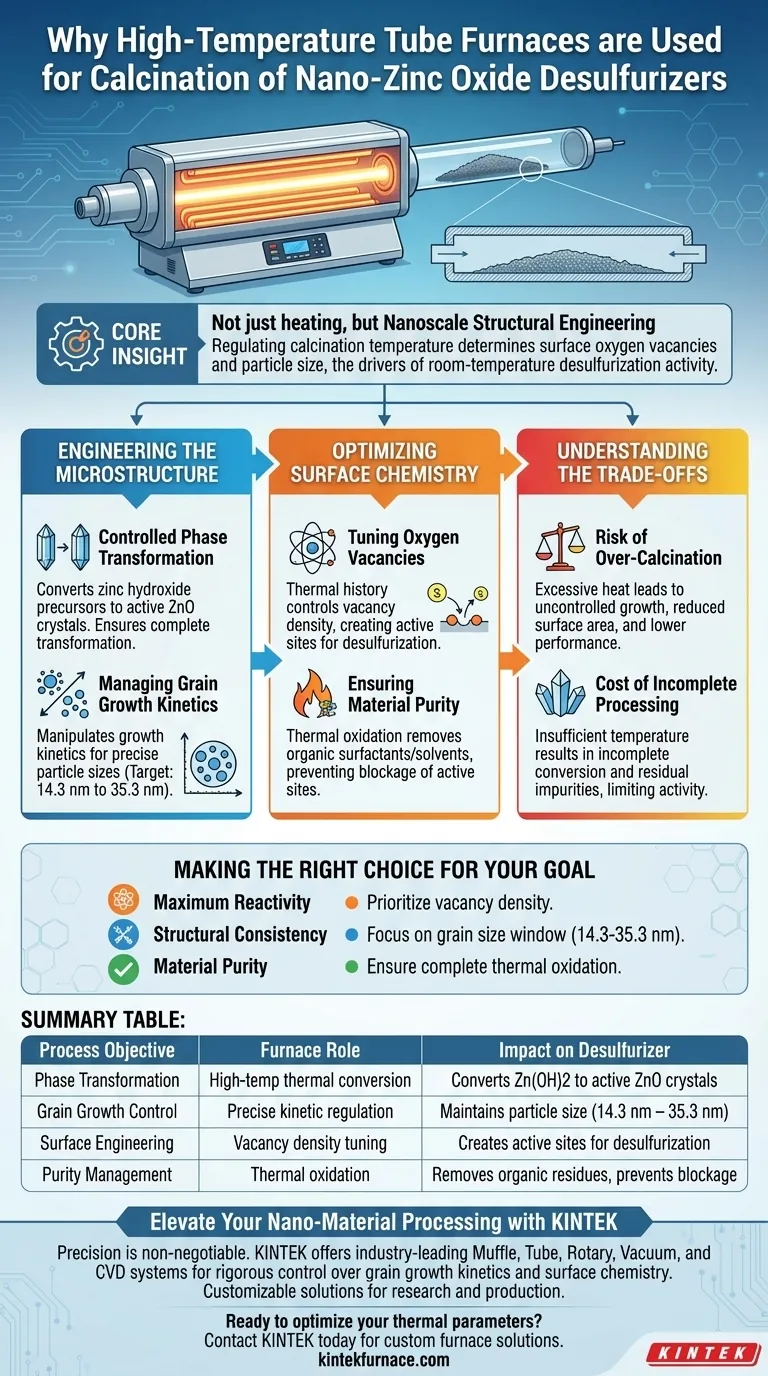

Core Insight The tube furnace is not merely a heating device; it is a tool for nanoscale structural engineering. By precisely regulating calcination temperature, you determine the density of surface oxygen vacancies and particle size, which are the fundamental drivers of the material's desulfurization activity at room temperature.

Engineering the Microstructure

Controlled Phase Transformation

The primary function of the furnace is to facilitate the conversion of the precursor material, specifically zinc hydroxide, into active zinc oxide crystals.

This process must be controlled to ensure the complete transformation of the crystal phase. A stable, high-temperature environment ensures that the resulting oxide powder achieves the necessary structural integrity for industrial application.

Managing Grain Growth Kinetics

The specific temperature settings within the tube furnace allow for precise manipulation of grain growth kinetics.

By adjusting these thermal parameters, researchers can restrict or encourage growth to attain specific particle sizes. In the context of nano-zinc oxide desulfurizers, this typically involves targeting a specific size range between 14.3 nm and 35.3 nm.

Optimizing Surface Chemistry

Tuning Oxygen Vacancies

The most critical outcome of this calcination process is the control over surface oxygen vacancies.

The distribution and density of these vacancies are not random; they are a direct result of the thermal history provided by the furnace. These vacancies act as active sites, directly determining how effectively the material can remove sulfur at room temperature.

Ensuring Material Purity

Supplementary to structural engineering, the furnace ensures the chemical purity of the final product.

The continuous high-temperature environment facilitates the thermal oxidation necessary to remove residual organic surfactants or solvents used during synthesis. eliminating these impurities prevents the blockage of active sites and ensures the material maintains high reactivity.

Understanding the Trade-offs

The Risk of Over-Calcination

While high temperatures are necessary for activation, excessive heat or prolonged exposure can lead to uncontrolled grain growth.

If the particles grow beyond the optimal nanometer range, the surface-area-to-volume ratio decreases. This reduction in surface area diminishes the number of available active sites, significantly lowering desulfurization performance.

The Cost of Incomplete Processing

Conversely, insufficient temperature control can result in incomplete phase transformation or residual impurities.

If the precursor is not fully converted or if organic residues remain, the material's theoretical activity levels cannot be reached. Precise thermal management is the only way to balance high crystallinity with high surface activity.

Making the Right Choice for Your Goal

To maximize the potential of your nano-zinc oxide desulfurizers, align your furnace parameters with your specific performance targets:

- If your primary focus is Maximum Reactivity: Prioritize temperature protocols that maximize the density of surface oxygen vacancies, as these are the primary drivers of desulfurization activity.

- If your primary focus is Structural Consistency: Focus on stabilizing the grain growth kinetics to maintain particle sizes strictly within the 14.3 nm to 35.3 nm window.

- If your primary focus is Material Purity: Ensure the calcination duration is sufficient to fully oxidize and remove any residual organic solvents or surfactants from the precursor stage.

Precision thermal processing is the bridge between raw chemical precursors and high-performance functional materials.

Summary Table:

| Process Objective | Furnace Role | Impact on Desulfurizer |

|---|---|---|

| Phase Transformation | High-temp thermal conversion | Converts zinc hydroxide into active ZnO crystals |

| Grain Growth Control | Precise kinetic regulation | Maintains particle size (14.3 nm – 35.3 nm) |

| Surface Engineering | Vacancy density tuning | Creates active sites for room-temp desulfurization |

| Purity Management | Thermal oxidation | Removes organic residues and prevents site blockage |

Elevate Your Nano-Material Processing with KINTEK

Precision is non-negotiable when engineering nanoscale materials. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically designed to give you rigorous control over grain growth kinetics and surface chemistry.

Backed by expert R&D and world-class manufacturing, our lab high-temperature furnaces are fully customizable to meet your unique calcination and thermal treatment requirements. Ensure the highest reactivity and material purity for your research and production.

Ready to optimize your thermal parameters? Contact KINTEK today to discuss your custom furnace solution.

Visual Guide

References

- Chunhong Shao, Xiu‐Li Yang. Study on the Surface Structure of Nano-ZnO Desulfurizers and Their Performance and Mechanism in H2S Removal at Room Temperature. DOI: 10.3390/catal15060547

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role do multi zone tube furnaces play in new energy research? Unlock Precise Thermal Control for Innovation

- How does a tube resistance furnace contribute to converting industrial sludge into high-activity geopolymer precursors?

- Why must a tube furnace used for the pyrolysis of tungsten-based nanocomposites be equipped with a precision gas flow?

- How is the structure of a multi station vacuum tube furnace divided? Optimize Your Lab's Thermal Processing

- How does a high-temperature tube furnace facilitate sulfur melt-diffusion? Precision Heating for PCFC/S Cathodes

- What is the necessity of annealing treatment for CuCo2O4@rGO? Optimize High-Crystallinity Synthesis in Tube Furnaces

- What is the role of a three-zone vertical furnace in the growth of alpha-Mg3Bi2 single crystals? | KINTEK Solution

- Why is the annealing process in a tube furnace under argon essential for NCMC heterostructures? Expert Insights