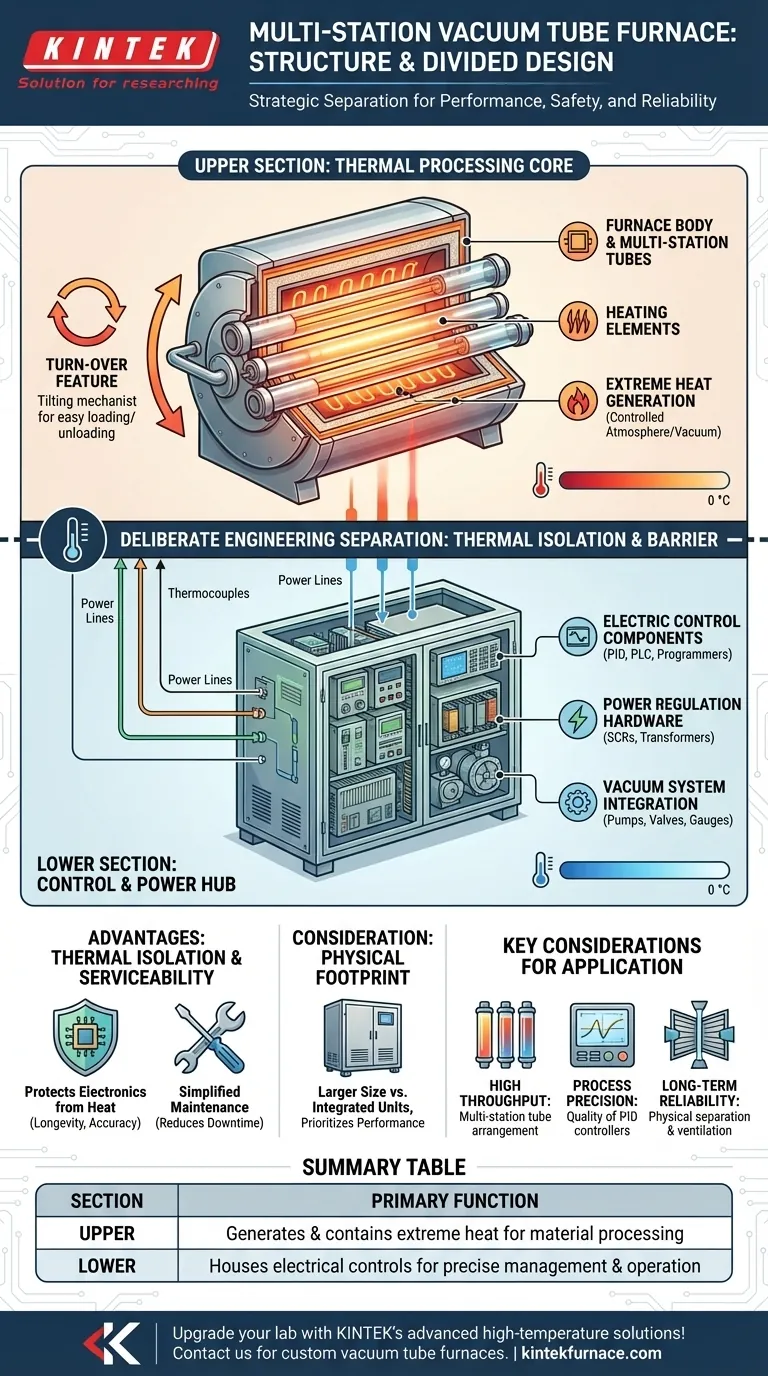

At its core, a multi-station vacuum tube furnace is strategically divided into two primary sections. The upper part contains the high-temperature furnace body and processing tubes, while the lower part houses all the essential electrical control components. This separation is not arbitrary; it is a fundamental design choice driven by principles of thermal management, safety, and operational reliability.

The dual-section structure of a multi-station vacuum tube furnace is a deliberate engineering solution. It isolates the heat-sensitive electronic controls from the extreme temperatures of the furnace, ensuring system longevity, precise process control, and simplified maintenance.

The Upper Section: The Thermal Processing Core

The upper section is where the primary material processing occurs. It is designed to generate and contain extreme heat under a controlled atmosphere or vacuum.

The Furnace Body and Tube

The main body of the furnace contains the heating elements, insulation, and the furnace tube itself. This tube is the sealed chamber where your samples are placed for heat treatment.

The "multi-station" aspect means the furnace has multiple tubes, allowing for simultaneous processing of different samples or for creating specific temperature gradients across a longer process zone.

The "Turn-Over" Feature

Many designs include a furnace body that can be turned over or tilted. This feature is not for the heating process itself but for facilitating easy loading and unloading of the furnace tube and samples, significantly improving operator ergonomics and safety.

The Lower Section: The Control and Power Hub

The lower section acts as the brain and central nervous system of the entire apparatus. Placing it physically below the heat source leverages natural convection to help keep it cool.

Electric Control Components

This area houses the temperature controllers (like PID controllers), process programmers, and any programmable logic controllers (PLCs) that automate the heating cycles. These components are the most sensitive to heat and require a stable operating environment for accuracy.

Power and Vacuum System Integration

The lower cabinet also contains the power regulation hardware, such as transformers and silicon-controlled rectifiers (SCRs), that manage the high electrical currents sent to the heating elements. Controls for the associated vacuum system—pumps, valves, and gauges—are typically integrated into this same control hub for centralized operation.

Understanding the Trade-offs of a Divided Structure

This common design represents a series of deliberate engineering trade-offs focused on performance and reliability.

Advantage: Thermal Isolation

The most significant benefit is thermal isolation. Electronics degrade quickly when exposed to high temperatures. Separating them from the furnace chamber dramatically increases the lifespan and reliability of the control system, preventing inaccurate readings and system failure.

Advantage: Serviceability

By separating the systems, maintenance becomes much simpler. An engineer can work on the control electronics in the lower section without needing to interact with or disassemble the high-temperature furnace assembly, reducing downtime.

Consideration: Physical Footprint

The main trade-off is a larger physical footprint. A single, integrated unit might be more compact, but the split design prioritizes long-term performance over minimal floor space. The connections between the upper and lower sections (power lines, thermocouples) also add a layer of complexity.

Key Structural Considerations for Your Application

Understanding this structure helps you evaluate a furnace based on your specific laboratory or production needs.

- If your primary focus is high throughput: The number and arrangement of the "multi-station" tubes in the upper section are your most critical features.

- If your primary focus is process precision: The quality and isolation of the PID controllers and thermocouples housed in the lower section are paramount.

- If your primary focus is long-term reliability: The physical separation and ventilation between the upper and lower sections is a key indicator of a well-engineered, durable system.

Ultimately, the divided structure of a multi-station vacuum tube furnace is a testament to purposeful design, ensuring that each component operates in its ideal environment.

Summary Table:

| Section | Key Components | Primary Function |

|---|---|---|

| Upper Section | Furnace body, heating elements, insulation, multi-station tubes | Generates and contains extreme heat for material processing in a controlled atmosphere or vacuum |

| Lower Section | Temperature controllers (PID), PLCs, power regulators (SCRs), vacuum system controls | Houses electrical controls for precise temperature management, automation, and system operation, isolated from heat |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable multi-station vacuum tube furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for enhanced efficiency and accuracy. Contact us today to discuss how we can optimize your thermal processing workflows!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis