In essence, a vertical tube furnace is a high-temperature heating device designed around a vertically oriented cylindrical chamber. It functions by using resistive heating elements to uniformly heat a sample contained within the tube, allowing for precise control over both temperature and the internal atmosphere for advanced material processing.

The decision to use a vertical tube furnace over a horizontal one is not arbitrary. It is a strategic choice driven by specific process requirements where gravity, spatial efficiency, and superior thermal uniformity are critical design considerations.

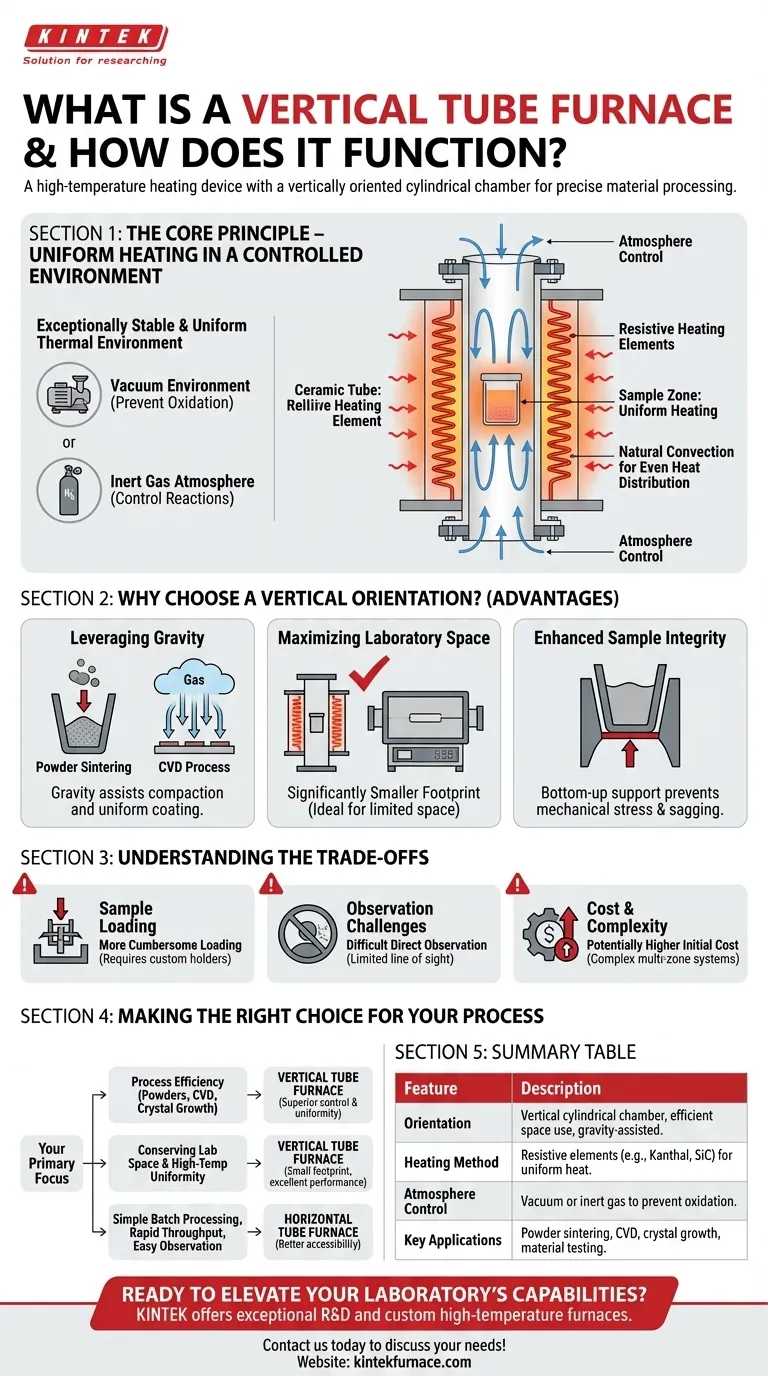

The Core Principle: Uniform Heating in a Controlled Environment

A vertical tube furnace's primary function is to create an exceptionally stable and uniform thermal environment. Its design is optimized to achieve this with high efficiency and precision.

How Resistive Heating Works

The furnace generates heat using resistive heating elements, typically made of materials like Kanthal or silicon carbide, that are wrapped around the central ceramic or quartz tube. As electricity passes through these elements, they resist the flow and generate intense, consistent heat.

This heat is then radiated inward, heating the tube and, by extension, the sample placed inside it.

Achieving Temperature Uniformity

The vertical orientation naturally promotes uniform heating. As air or gas inside the tube is heated, it rises, creating a natural convection current. This circulation helps distribute heat evenly along the entire length of the sample zone, minimizing "hot spots" or temperature gradients that can occur in other designs.

Controlling the Atmosphere

The ends of the tube are sealed with flanges, allowing the internal environment to be precisely managed. The furnace can be evacuated to create a vacuum or filled with a specific gas, such as argon or nitrogen, to create an inert atmosphere. This control is critical for preventing oxidation or unwanted chemical reactions during high-temperature processing.

Why Choose a Vertical Orientation?

The vertical design offers distinct advantages that make it the optimal choice for certain applications. The decision to use one is almost always tied to the physics of the process itself.

Leveraging Gravity for Processing

Gravity is a key factor in a vertical furnace. It is ideal for processes like powder sintering, where gravity helps compact the material, or for experiments where a sample must be dropped into the hot zone at a precise moment.

In processes like Chemical Vapor Deposition (CVD), precursor gases can be introduced at the top, flowing down over substrates aided by gravity, leading to a more uniform coating.

Maximizing Laboratory Space

Compared to their horizontal counterparts, vertical tube furnaces have a significantly smaller footprint. For laboratories where floor space is at a premium, a vertical design offers a major practical advantage without compromising on performance or capacity.

Enhanced Sample Integrity

For certain delicate samples or those processed in crucibles, the bottom-up support in a vertical furnace prevents sagging or mechanical stress that can occur at high temperatures in a horizontal orientation.

Understanding the Trade-offs

While powerful, the vertical design is not universally superior. Understanding its limitations is key to making an informed decision.

Sample Loading and Accessibility

Loading and unloading samples can be more cumbersome in a vertical furnace. It often requires custom holders or fixtures to position samples correctly within the central hot zone, whereas a horizontal furnace allows for easier placement along a flat surface.

Observation Challenges

Directly observing a sample during processing is more difficult in a vertical setup. While some models may incorporate viewports, the orientation inherently limits lines of sight compared to an easily accessible horizontal tube.

Cost and Complexity

The specialized design, particularly for larger or more complex multi-zone systems, can sometimes result in higher initial costs compared to a standard horizontal furnace. The need for support structures can also add to the overall complexity.

Making the Right Choice for Your Process

Your specific application and goals should dictate your choice of furnace.

- If your primary focus is process efficiency involving powders, crystal growth, or vapor deposition (CVD): The vertical design's use of gravity and natural convection offers superior control and uniformity.

- If your primary focus is conserving lab space while requiring high-temperature uniformity: The small footprint and excellent thermal performance make the vertical furnace an ideal choice.

- If your primary focus is simple batch processing, rapid sample throughput, or easy observation: You should evaluate if a horizontal tube furnace might better suit your workflow due to its accessibility.

Ultimately, selecting the right furnace is about aligning the equipment's fundamental design with the specific physics of your experimental goal.

Summary Table:

| Feature | Description |

|---|---|

| Orientation | Vertical cylindrical chamber for efficient space use and gravity-assisted processes |

| Heating Method | Resistive heating elements (e.g., Kanthal, silicon carbide) for uniform temperature distribution |

| Atmosphere Control | Vacuum or inert gas (e.g., argon, nitrogen) to prevent oxidation and control reactions |

| Key Applications | Powder sintering, Chemical Vapor Deposition (CVD), crystal growth, and high-temperature material testing |

| Advantages | Superior thermal uniformity, small footprint, enhanced sample integrity, and natural convection for even heating |

| Limitations | More complex sample loading, limited observation, and potentially higher cost compared to horizontal furnaces |

Ready to elevate your laboratory's capabilities with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization for precise experimental requirements. Whether you're in materials science, research, or industrial processing, we can help you achieve superior results with reliable, efficient equipment. Contact us today to discuss how our vertical tube furnaces and other solutions can transform your processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis