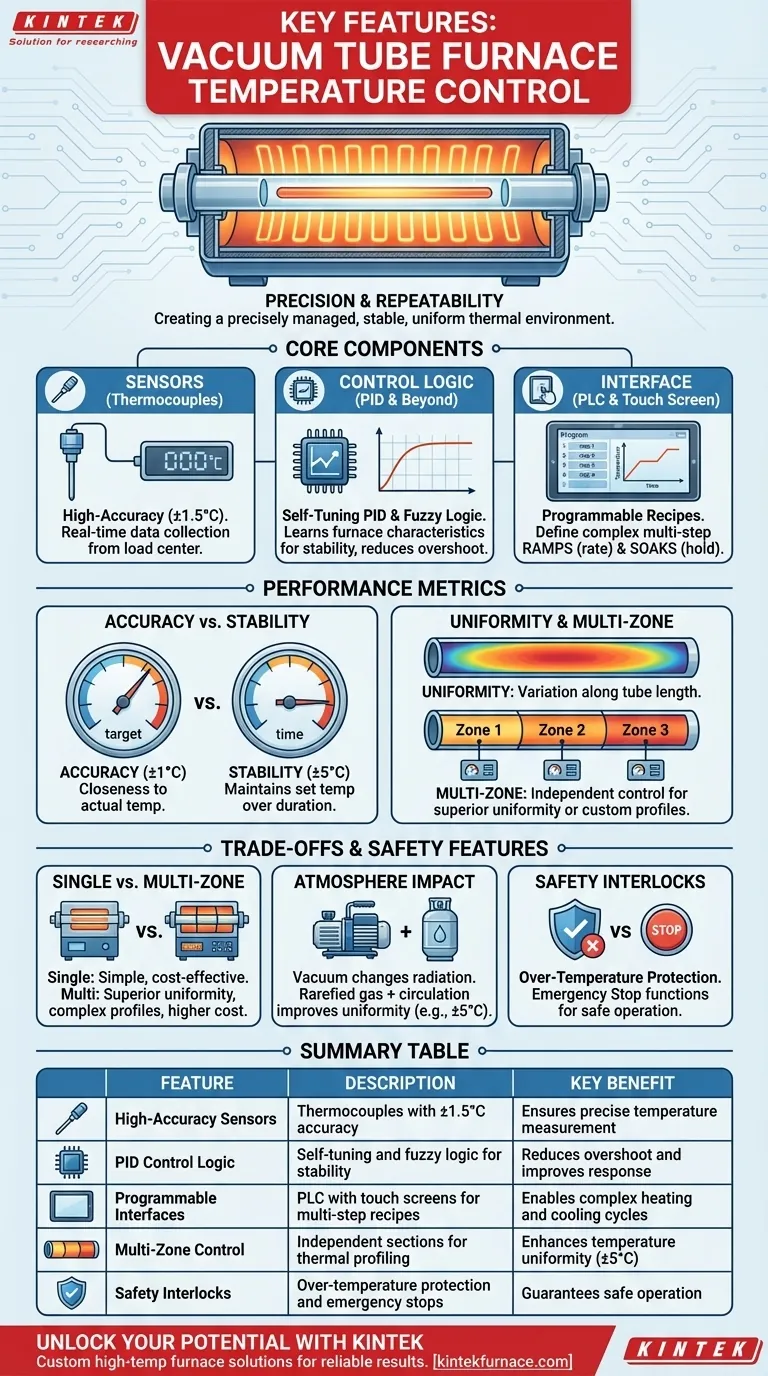

At its core, temperature control in a vacuum tube furnace is a sophisticated system designed for precision and repeatability. Key features include high-accuracy sensors like thermocouples, advanced control logic such as PID, and programmable interfaces that allow for complex heating and cooling cycles.

The purpose of a vacuum tube furnace's temperature control system is not simply to reach a set temperature. It is to create a precisely managed, stable, and uniform thermal environment over a specific duration, which is the critical factor for successful advanced material processing.

The Core Components of Temperature Control

A modern furnace's temperature control is an integrated system where each part plays a crucial role in achieving the final result. Understanding these components demystifies how such high precision is possible.

Temperature Measurement: The Thermocouple

The thermocouple is the primary sensor of the system. It is a robust device that measures temperature by detecting changes in voltage between two different metals.

Modern systems use high-grade thermocouples, often placed at the center of the load, to provide real-time temperature data directly to the controller with an indicated accuracy that can reach ±1.5°C.

The Control Logic: PID and Beyond

The controller is the brain of the operation. The most common method is PID (Proportional-Integral-Derivative) control. This algorithm continuously calculates the difference between the desired temperature (setpoint) and the measured temperature, adjusting the heating element power to minimize this error.

Many furnaces enhance PID with self-tuning and fuzzy logic technologies. These advancements allow the controller to automatically "learn" the thermal characteristics of the furnace, optimizing its response for faster stabilization and reduced temperature overshoot.

User Interface and Programming

How an operator interacts with the system is a key feature. Modern furnaces have moved from simple dials to advanced interfaces.

Programmable Logic Controllers (PLC) paired with color touch screens are common. This allows users to program complex recipes with multiple steps, defining precise ramps (rate of temperature change) and soaks (holding at a temperature for a set time).

Key Performance Metrics of Temperature Control

The effectiveness of a control system is measured by several key performance indicators. These numbers define the furnace's capabilities and suitability for a specific task.

Accuracy vs. Stability

These two terms are not interchangeable. Accuracy refers to how close the displayed temperature is to the actual temperature, often within ±1°C.

Stability, on the other hand, describes how well the furnace maintains a set temperature over time within the heating zone. A typical stability specification is ±5°C, ensuring the material experiences a consistent thermal environment.

Uniformity and Multi-Zone Control

Uniformity refers to the variation in temperature along the length of the heated tube. For many processes, even heating is critical.

To achieve superior uniformity or to create intentional temperature gradients, some furnaces feature multi-zone control. This divides the heating tube into sections, each with its own thermocouple and independent controller, allowing for exceptionally precise thermal profiling.

Understanding the Trade-offs and Safety Features

Choosing the right furnace involves balancing performance with practicality. The control system plays a significant role in this balance and is also central to safe operation.

Single-Zone vs. Multi-Zone

A single-zone furnace is simpler, more cost-effective, and perfectly adequate for many standard applications.

A multi-zone furnace provides superior temperature uniformity and the flexibility to create custom thermal profiles, but it comes at a higher cost and complexity. The choice depends entirely on the precision required by your process.

The Impact of Atmosphere

The environment inside the tube directly affects heat transfer. Operating under a deep vacuum changes how heat radiates.

Conversely, using a rarefied gas with forced circulation can improve temperature uniformity across the workpiece, often keeping the temperature difference within that ±5°C range. The control system must be able to compensate for these different conditions.

Essential Safety Interlocks

Advanced control is not just about performance; it's also about safety. All reputable furnaces integrate safety features into their control logic.

Key functions include over-temperature protection, which automatically shuts down the heating elements if a set limit is exceeded, and emergency stop functions that halt all operations immediately.

Making the Right Choice for Your Application

The ideal set of temperature control features depends entirely on your specific scientific or industrial goal.

- If your primary focus is process repeatability and high-throughput: Look for a furnace with PLC control, integrated data logging, and a self-tuning PID algorithm.

- If your primary focus is novel material research with complex thermal profiles: Prioritize a multi-zone furnace with a highly programmable touch screen interface for creating custom ramps and soaks.

- If your primary focus is general-purpose heat treatment on a budget: A single-zone furnace with a reliable, standard PID controller provides excellent performance and value.

Ultimately, understanding these control features empowers you to select the precise tool needed to achieve reliable and repeatable results in your work.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| High-Accuracy Sensors | Thermocouples with ±1.5°C accuracy | Ensures precise temperature measurement |

| PID Control Logic | Self-tuning and fuzzy logic for stability | Reduces overshoot and improves response |

| Programmable Interfaces | PLC with touch screens for multi-step recipes | Enables complex heating and cooling cycles |

| Multi-Zone Control | Independent sections for thermal profiling | Enhances temperature uniformity (±5°C) |

| Safety Interlocks | Over-temperature protection and emergency stops | Guarantees safe operation |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs, delivering reliable and repeatable results. Contact us today to discuss how our tailored solutions can enhance your material processing and research efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide