To install a multi-zone tube furnace, you must first prepare a suitable location with proper ventilation and a stable, grounded power supply. The core physical installation involves carefully placing the furnace tube symmetrically within the heating chamber, ensuring it does not touch any heating elements, and then assembling the flanges in the correct sequence to create a perfect seal for atmospheric control.

A successful installation is not merely about assembling components. It is about systematically creating a controlled, stable, and safe environment that is foundational for achieving accurate and repeatable experimental outcomes.

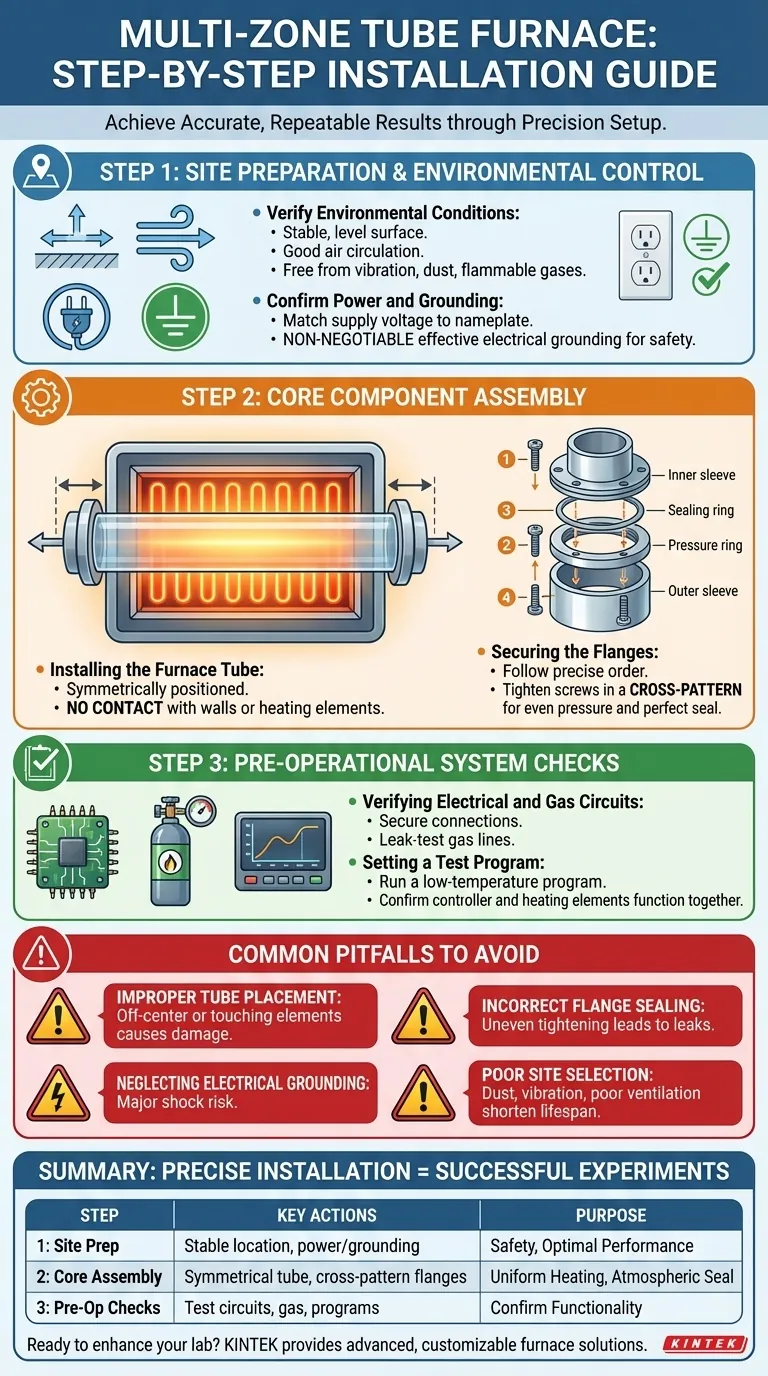

Step 1: Site Preparation and Environmental Control

Before you even unbox the furnace, the chosen location dictates its performance and safety. An unsuitable environment is a common source of failed experiments and safety risks.

Verify Environmental Conditions

The furnace must be placed on a stable, level surface in a location with good air circulation. This helps dissipate heat and prevents overheating of the control electronics.

The area must be free of vibration, high dust levels, and any flammable or explosive gases. Vibration can disturb sensitive samples, while dust and corrosive gases can damage the furnace's internal components.

Confirm Power and Grounding

Confirm your facility’s power supply voltage matches the furnace’s requirements, which are listed on its nameplate. A mismatch can permanently damage the equipment.

Effective electrical grounding is non-negotiable. It is a critical safety measure to prevent electric shock. Always verify a proper ground connection before connecting the main power.

Step 2: Core Component Assembly

The precision of the physical assembly directly impacts the uniformity of the heating and the integrity of your controlled atmosphere.

Installing the Furnace Tube

The furnace tube must be installed symmetrically, positioned exactly in the middle of the furnace chamber. Adjust it so an equal length of the tube extends from both ends.

Critically, the tube must not touch the furnace walls or heating elements. Contact can cause localized overheating, damage to the tube, and damage to the elements, leading to inaccurate temperature profiles and costly repairs. The tube should be able to rotate freely once positioned.

Securing the Flanges

A proper seal is essential for vacuum or inert gas applications. Flanges must be assembled in a precise order: inner flange sleeve, sealing ring, pressure ring, and finally the outer flange sleeve.

When tightening the screws on the flange, do so in a cross-pattern, like tightening lug nuts on a car wheel. This ensures even pressure and prevents the flange from skewing, which would compromise the seal.

Step 3: Pre-Operational System Checks

Before committing a valuable sample, a final verification ensures all systems are functioning as intended.

Verifying Electrical and Gas Circuits

Before the first heating cycle, double-check that all electrical connections are secure and that any gas lines are properly connected and leak-tested.

Turn on the main power switch. The controller should initialize and display its home screen, confirming the electronics are operational.

Setting a Test Program

Set a simple, low-temperature heating program for each zone according to your experimental needs. Start the heating system and observe the controller display.

The system should show the temperature rising, confirming that the control logic and heating elements are working in tandem. This simple test validates the core functionality of the furnace before you begin your actual experiment.

Common Pitfalls to Avoid

Many installation issues stem from a few common, preventable mistakes. Being aware of them is the first step to avoiding them.

Improper Tube Placement

Placing the tube off-center or in contact with the heating elements is the most frequent cause of poor temperature uniformity and component damage. Always verify its position.

Incorrect Flange Sealing

An improperly sealed flange will leak, making it impossible to maintain a vacuum or a pure inert atmosphere. This silently invalidates any experiment that relies on atmospheric control. Always tighten screws evenly and check the seal.

Neglecting Electrical Grounding

Failure to ensure a solid ground connection creates a significant risk of electric shock for the operator. It is a critical safety step that must never be skipped.

Poor Site Selection

Placing the furnace in a dusty, high-vibration, or poorly ventilated area will shorten its lifespan and compromise the quality of your results. The environment is part of the instrument.

Making the Right Choice for Your Goal

Finalize your installation by focusing on the details that matter most for your specific application.

- If your primary focus is experimental accuracy: Your highest priority is the perfectly symmetrical placement of the tube and the absolute integrity of the flange seal.

- If your primary focus is operational safety: Your attention must be on verifying effective electrical grounding and ensuring the site has adequate ventilation, free from all flammable materials.

- If your primary focus is long-term reliability: Implement a routine schedule to inspect power circuits, clean the furnace, and check for gas leaks before they become a problem.

A methodical and precise installation is the foundation upon which every successful experiment is built.

Summary Table:

| Step | Key Actions | Purpose |

|---|---|---|

| 1: Site Preparation | Verify stable location, ventilation, power supply, and grounding | Ensure safety and optimal performance |

| 2: Core Assembly | Install tube symmetrically, secure flanges with cross-pattern tightening | Achieve uniform heating and atmospheric seal |

| 3: Pre-Operational Checks | Test electrical circuits, gas lines, and heating programs | Confirm system functionality before use |

Ready to enhance your lab's capabilities with a reliable multi-zone tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can bring accuracy, safety, and long-term reliability to your research!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing