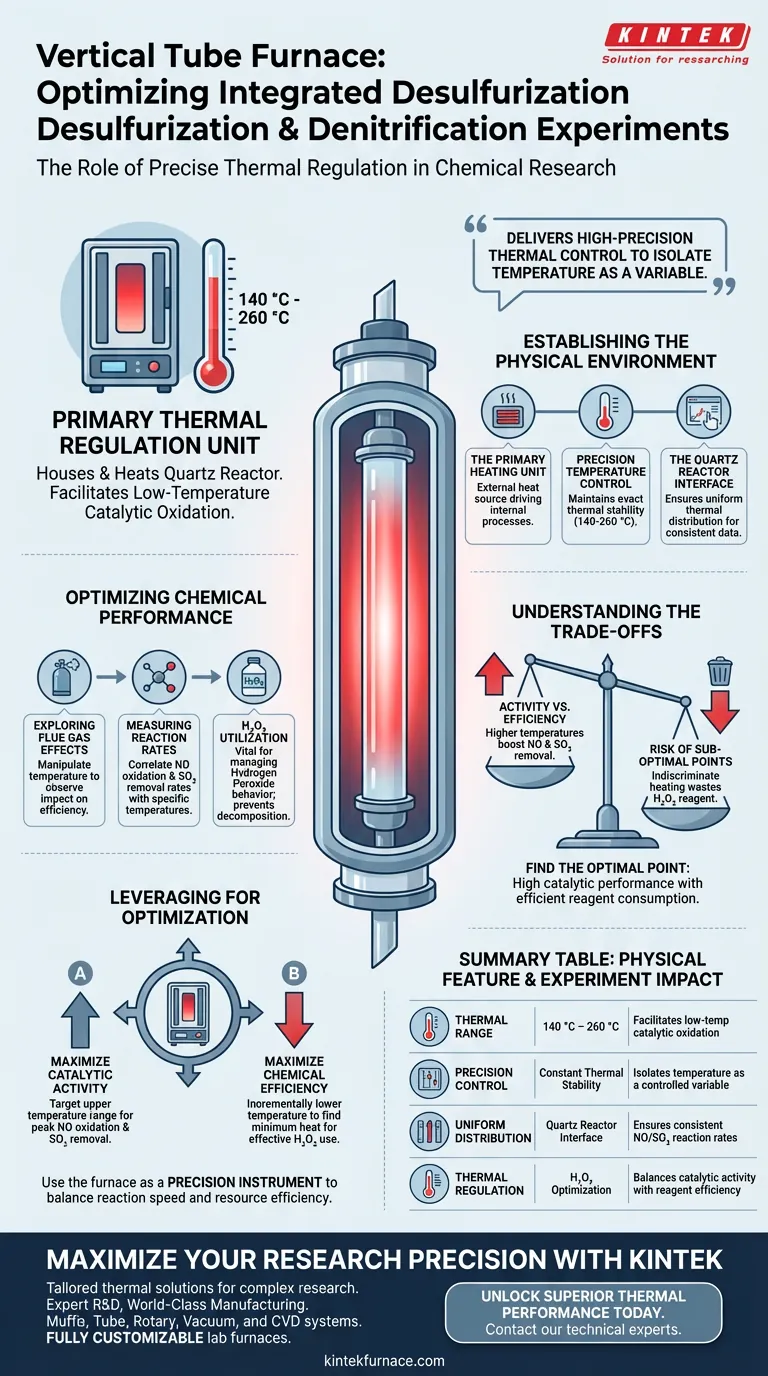

A vertical tube furnace acts as the primary thermal regulation unit for integrated desulfurization and denitrification experiments, specifically designed to house and heat a quartz reactor. Its central physical contribution is the provision of a precisely controlled temperature environment, typically maintained between 140 °C and 260 °C, to facilitate catalytic oxidation.

By delivering high-precision thermal control, the furnace allows researchers to isolate temperature as a variable, identifying the specific conditions that maximize removal rates while minimizing chemical waste.

Establishing the Physical Environment

The Primary Heating Unit

The vertical tube furnace serves as the foundational hardware for the experiment. It surrounds the quartz reactor, acting as the external heat source that drives the internal chemical processes.

Precision Temperature Control

The core function of this equipment is maintaining exact thermal stability. It does not merely heat the apparatus but ensures the temperature remains constant within the specified low-temperature window (140-260 °C).

The Quartz Reactor Interface

The physical conditions created by the furnace are transferred directly to the quartz reactor inside. This setup ensures that the flue gas passing through the reactor experiences uniform thermal distribution, which is critical for consistent experimental data.

Optimizing Chemical Performance

Exploring Flue Gas Effects

The precise control allows researchers to manipulate the temperature of the flue gas systematically. By adjusting the furnace settings, you can observe how thermal changes directly impact the efficiency of the system.

Measuring Reaction Rates

Specific attention is paid to two key metrics: NO oxidation rates and SO2 removal rates. The furnace environment enables the correlation of these rates with specific temperature points to determine kinetic behavior.

H2O2 Utilization

In these specific experiments, the furnace conditions are vital for managing Hydrogen Peroxide (H2O2) behavior. The temperature must be sufficient to drive reactions without causing inefficient decomposition or waste of the H2O2 reagent.

Understanding the Trade-offs

The Balance of Activity vs. Efficiency

A critical trade-off exists within the 140-260 °C range provided by the furnace. Higher temperatures generally increase catalytic activity, potentially boosting NO and SO2 removal.

The Risk of Sub-optimal Points

However, increasing temperature indiscriminately can lead to poor H2O2 utilization. The challenge lies in using the furnace to find the "optimal point"—a specific temperature where catalytic performance is high, but reagent consumption remains efficient.

Leveraging the Furnace for Optimization

To derive the most value from your vertical tube furnace setup, align your thermal settings with your specific experimental metrics.

- If your primary focus is maximizing catalytic activity: Target the upper end of the provided temperature range to test the limits of NO oxidation and SO2 removal rates.

- If your primary focus is chemical efficiency: Utilize the furnace's precision to incrementally lower temperatures, identifying the minimum heat required for effective H2O2 utilization.

Success in these experiments relies on using the furnace not just as a heater, but as a precision instrument to balance reaction speed with resource efficiency.

Summary Table:

| Physical Feature | Functional Contribution | Impact on Experiment |

|---|---|---|

| Thermal Range | 140 °C – 260 °C | Facilitates low-temperature catalytic oxidation |

| Precision Control | Constant Thermal Stability | Isolates temperature as a controlled variable |

| Uniform Distribution | Quartz Reactor Interface | Ensures consistent NO/SO2 reaction rates |

| Thermal Regulation | H2O2 Optimization | Balances catalytic activity with reagent efficiency |

Maximize Your Research Precision with KINTEK

Are you looking to optimize your catalytic oxidation rates? KINTEK provides industry-leading thermal solutions tailored for complex chemical research. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems.

Whether you need precise low-temperature control for desulfurization or high-temp durability for material synthesis, our lab furnaces are fully customizable to meet your unique experimental needs.

Unlock superior thermal performance today. Contact our technical experts to find the perfect furnace for your laboratory.

Visual Guide

References

- Yanyuan Bai, Qi Xiao. Experimental study on integrated desulfurization and denitrification of low-temperature flue gas by oxidation method. DOI: 10.1038/s41598-024-53765-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does an industrial high-temperature tube furnace control crystallization quality? Master LiScO2:Cr3+ Synthesis

- What is the temperature range of a tube furnace? Choose the Right Model for Your Process

- What maintenance practices are recommended for a multi zone tube furnace? Ensure Safety and Precision in Your Lab

- What are the common uses of vertical fluidized bed tube furnaces in laboratory research? Discover Precision Thermal Solutions

- What are some common applications of vertical tube furnaces? Unlock Precision in High-Temp Processes

- What are the key capabilities of the 3-Zone tube furnace? Achieve Precise Thermal Control for Your Lab

- How is a tube furnace designed to operate at 1200°C? Precision Engineering for Extreme Heat

- How do industrial-grade tube furnaces facilitate the preparation of high-stability perovskites? Enhance Phase Purity