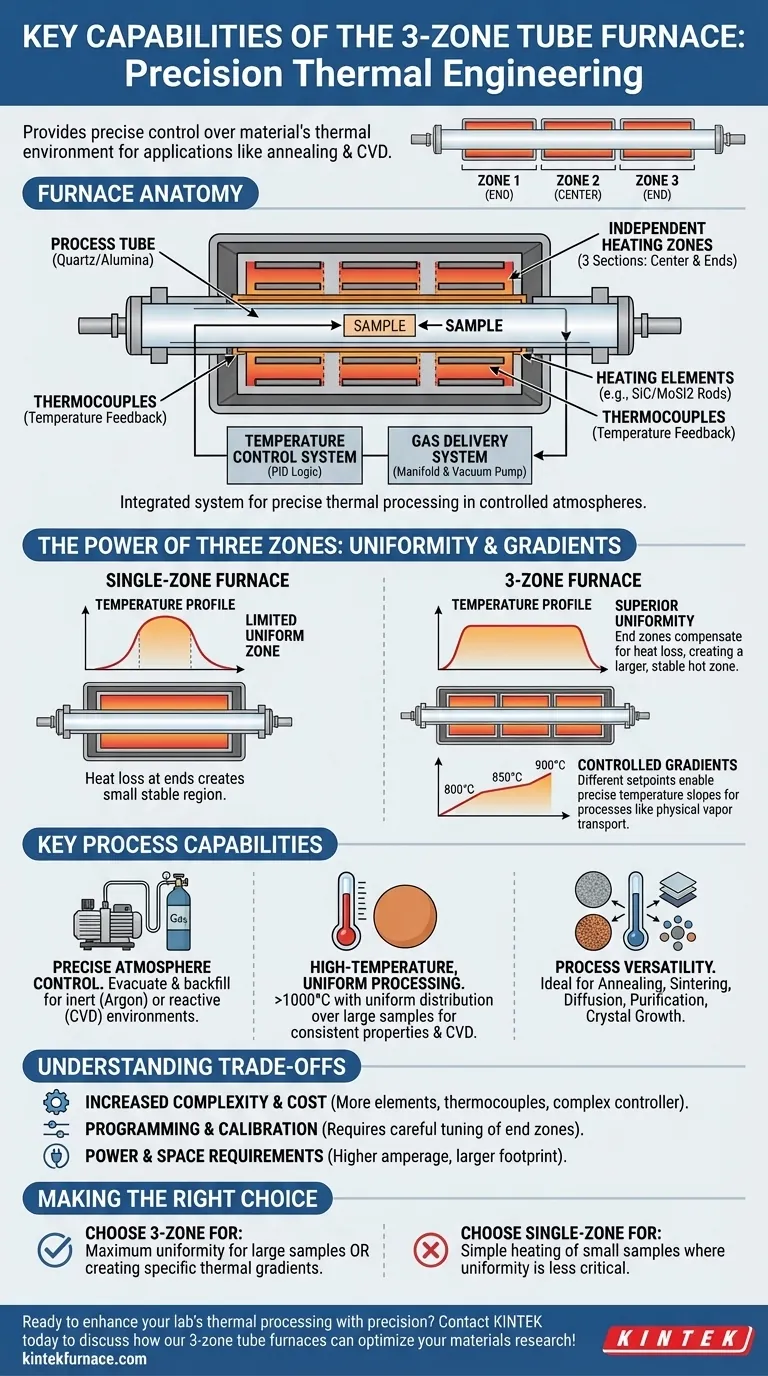

At its core, a 3-zone tube furnace provides precise control over a material's thermal environment, primarily for applications like annealing and chemical vapor deposition (CVD). Its key capabilities include accommodating samples up to 60mm, managing gas flow via a manifold, and, most importantly, creating highly uniform or specifically profiled temperature zones that are impossible to achieve with a single heating zone.

A 3-zone tube furnace is not simply a tool for heating; it is a precision instrument for thermal engineering. Its primary advantage over a single-zone furnace is the ability to actively compensate for heat loss at the ends of the tube, resulting in a significantly larger, more stable, and uniform hot zone for processing materials.

Understanding the Furnace Anatomy

To grasp its capabilities, we must first understand its fundamental components. A tube furnace is a system of integrated parts designed for precise thermal processing in a controlled atmosphere.

The Process Tube

The core of the furnace is the process tube, which contains the sample and the atmosphere. These are typically made of quartz for temperatures up to ~1200°C or high-purity alumina (corundum) for higher temperatures, ensuring resistance to thermal shock and preventing contamination.

The Heating System

Surrounding the tube are the heating elements. These are often resistance wires or robust silicon carbide (SiC) / molybdenum disilicide (MoSi2) rods. In a 3-zone furnace, these elements are separated into three distinct, independently controlled sections: a large center zone and two smaller end zones.

The Control and Gas Systems

A sophisticated temperature control system, often using PID (Proportional-Integral-Derivative) logic, reads data from thermocouples and adjusts power to each of the three zones independently. A gas delivery system, often a pre-plumbed manifold, allows for the introduction of inert or reactive gases and can be paired with a vacuum pump to achieve a high-vacuum environment.

The Power of Three Zones: Uniformity and Gradients

The defining feature of this furnace is its multi-zone control. This capability directly addresses the fundamental challenge of thermal processing in a tube: heat naturally escapes from the ends.

Achieving Superior Uniformity

In a single-zone furnace, the temperature profile peaks in the center and drops off significantly toward the ends, creating a very small region of stable, uniform temperature.

A 3-zone furnace solves this by allowing the two end zones to be set at a higher temperature than the center zone. This extra heat actively counteracts the natural thermal loss, creating a much longer, flatter, and more uniform temperature profile across the center of the furnace.

Creating Controlled Gradients

Beyond uniformity, the independent zones can be programmed to create a precise temperature gradient. By setting the three zones to different temperatures (e.g., 800°C, 850°C, 900°C), you can drive processes like physical vapor transport, where material sublimates in a hot zone and crystallizes in a cooler zone.

Key Capabilities Explained

The multi-zone design enables several critical process capabilities that are essential in materials research and advanced manufacturing.

Precise Atmosphere Control

The sealed tube design is crucial. It allows operators to evacuate the air with a vacuum pump and backfill with a specific gas. This is non-negotiable for processes that require an inert atmosphere (like Argon to prevent oxidation during annealing) or a reactive atmosphere for CVD.

High-Temperature, Uniform Processing

These furnaces can routinely exceed 1000°C, with some specialized models going much higher. The 3-zone configuration ensures that this high temperature is uniformly distributed over a large sample area, which is critical for consistent material properties, uniform film deposition in CVD, or growing large, defect-free crystals.

Process Versatility

The combination of precise temperature and atmosphere control makes the 3-zone furnace a versatile tool. It can be used for a wide range of applications, including annealing, sintering, diffusion, purification, and crystal growth.

Understanding the Trade-offs

While powerful, a 3-zone furnace is not always the necessary choice. Its advantages come with specific considerations.

Increased Complexity and Cost

A 3-zone furnace has more heating elements, more thermocouples, and a more complex controller. This inevitably leads to a higher initial purchase price and potentially more complex maintenance compared to a simpler single-zone model.

Programming and Calibration

Achieving a perfectly flat thermal profile requires careful programming and calibration. The operator must tune the setpoints of the end zones relative to the center zone to achieve the desired result, which can involve some initial trial and error.

Power and Space Requirements

Three heating zones draw more power than one. These systems typically require higher-amperage electrical service and have a larger physical footprint in the lab, which must be planned for.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the precision your process demands.

- If your primary focus is maximum thermal uniformity for large samples: A 3-zone furnace is the correct instrument, as it is specifically designed to create a large, stable hot zone.

- If your primary focus is creating a specific thermal gradient: A 3-zone furnace is essential for applications like vapor transport that rely on a controlled temperature slope.

- If your primary focus is simple heating of small samples where uniformity is less critical: A more cost-effective single-zone furnace is likely sufficient for your needs.

Ultimately, investing in a 3-zone furnace is a decision to prioritize precise control over the thermal environment of your material.

Summary Table:

| Capability | Description |

|---|---|

| Multi-Zone Control | Independent temperature control for three zones to achieve uniformity or gradients. |

| Precise Atmosphere | Sealed tube with gas manifold for inert or reactive atmospheres and vacuum compatibility. |

| High-Temperature Operation | Capable of exceeding 1000°C with uniform heat distribution for consistent results. |

| Process Versatility | Suitable for annealing, CVD, sintering, diffusion, and crystal growth applications. |

| Sample Accommodation | Handles samples up to 60mm in diameter for various experimental setups. |

Ready to enhance your lab's thermal processing with precision? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our 3-zone tube furnaces can optimize your materials research and achieve superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety