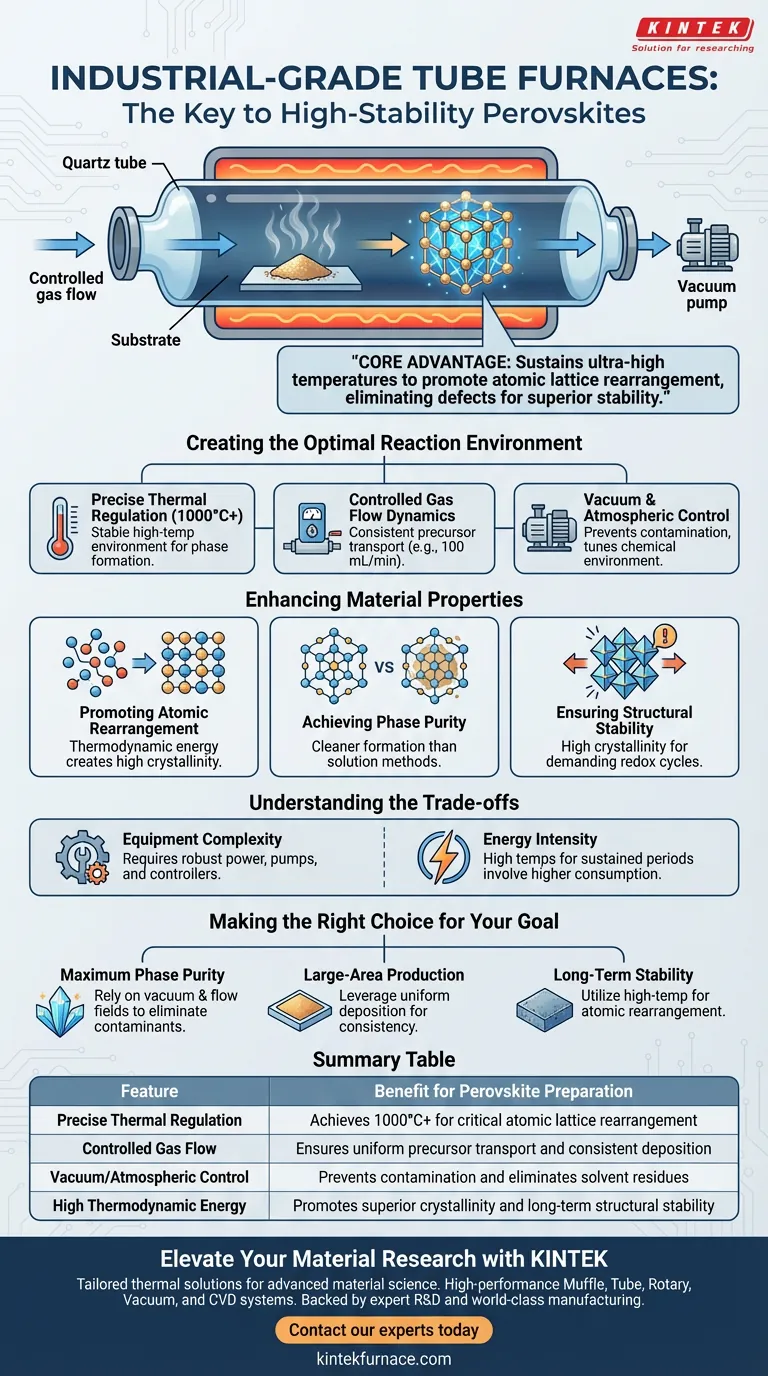

Industrial-grade tube furnaces facilitate high-stability perovskite preparation by acting as a precise reaction vessel that governs the sublimation and deposition of precursors under controlled vacuum or atmospheric conditions. By maintaining a stable high-temperature environment and a specific gas flow field, these systems ensure precursors deposit uniformly onto substrates, resulting in superior structural integrity compared to solution-based methods.

The core advantage of the tube furnace lies in its ability to sustain ultra-high temperatures that promote atomic lattice rearrangement. This thermodynamic process eliminates defects and creates high-crystallinity structures essential for long-term material stability and performance.

Creating the Optimal Reaction Environment

Precise Thermal Regulation

The tube furnace serves as the primary reaction space, providing a highly stable thermal environment. Industrial-grade systems can achieve ultra-high temperatures, such as 1000°C, which are often necessary for the formation of specific perovskite phases like CaMnO3.

Controlled Gas Flow Dynamics

Beyond heat, these furnaces manage the gas flow field with high precision. For example, maintaining a specific airflow rate (e.g., 100 mL per minute) ensures the transport of vaporized precursors is consistent.

Vacuum and Atmospheric Control

The system allows precursors to sublimate under vacuum or within specific gas atmospheres. This control prevents contamination and ensures the chemical environment is perfectly tuned for the desired reaction kinetics.

Enhancing Material Properties

Promoting Atomic Rearrangement

The sustained high temperatures within the furnace drive the rearrangement of lattice atoms. This thermodynamic energy allows the material to settle into its most stable configuration, leading to a structure with high crystallinity.

Achieving Phase Purity

Perovskites produced via this vapor deposition method exhibit superior phase purity. Unlike solution-based methods which may leave solvent residues or defects, the furnace environment ensures a cleaner formation process.

Ensuring Structural Stability

The high crystallinity resulting from this process directly translates to structural stability. This is critical for applications requiring lattice oxygen release capability during redox cycles, ensuring the material does not degrade under stress.

Understanding the Trade-offs

Equipment Complexity

Achieving this level of stability requires significant infrastructure. Unlike simple solution processing, industrial-grade tube furnaces require robust power supplies, vacuum pumps, and precise flow controllers to function correctly.

Energy Intensity

The requirement to maintain ultra-high temperatures (up to 1000°C) for sustained periods involves higher energy consumption. This is a necessary cost to induce the atomic rearrangement required for superior material quality.

Making the Right Choice for Your Goal

- If your primary focus is Maximum Phase Purity: Rely on the tube furnace’s controlled vacuum and flow fields to eliminate contaminants common in solution-based synthesis.

- If your primary focus is Large-Area Production: Leverage the furnace's ability to deposit sublimated precursors uniformly across downstream substrates to ensure consistency.

- If your primary focus is Long-Term Stability: Utilize the high-temperature capabilities to drive atomic rearrangement, ensuring the lattice structure is robust enough for demanding redox cycles.

By prioritizing thermal precision and flow control, industrial tube furnaces transform raw precursors into highly crystalline, industrial-ready perovskite materials.

Summary Table:

| Feature | Benefit for Perovskite Preparation |

|---|---|

| Precise Thermal Regulation | Achieves 1000°C+ for critical atomic lattice rearrangement |

| Controlled Gas Flow | Ensures uniform precursor transport and consistent deposition |

| Vacuum/Atmospheric Control | Prevents contamination and eliminates solvent residues |

| High Thermodynamic Energy | Promotes superior crystallinity and long-term structural stability |

Elevate Your Material Research with KINTEK

Are you looking to achieve maximum phase purity and structural stability in your perovskite synthesis? KINTEK provides industry-leading thermal solutions tailored for advanced material science.

Backed by expert R&D and world-class manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need ultra-precise gas flow dynamics or customizable high-temperature environments, our furnaces are engineered to meet your unique laboratory and industrial requirements.

Ready to optimize your vapor deposition process? Contact our experts today to find the perfect customizable furnace for your research needs!

Visual Guide

References

- Maoding Cheng, Qinglong Jiang. Progress and Application of Halide Perovskite Materials for Solar Cells and Light Emitting Devices. DOI: 10.3390/nano14050391

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What role does a high-vacuum tube furnace (CVD) play in HEA@CNT synthesis? Master Nanocomposite In-Situ Growth

- How does the environmental control within a high-temperature tube furnace affect Ag-N-C catalyst pyrolysis?

- What is a vertical tube furnace used for in semiconductor manufacturing? Essential for High-Precision Thermal Processing

- What physical conditions does a tube furnace provide for core-shell catalysts? Precision Reduction & SMSI Control

- Why is temperature control technology important in tube furnaces? Ensure Precision and Efficiency in Your Lab

- What role does a tube pyrolysis reactor play in sludge and chloride co-pyrolysis? Enhanced Heavy Metal Removal

- What materials are recommended for constructing a tube furnace for high temperatures? Essential Guide for Labs

- What is the maximum temperature a High Temperature Tube Furnace can reach? Up to 1800°C for Advanced Lab Needs