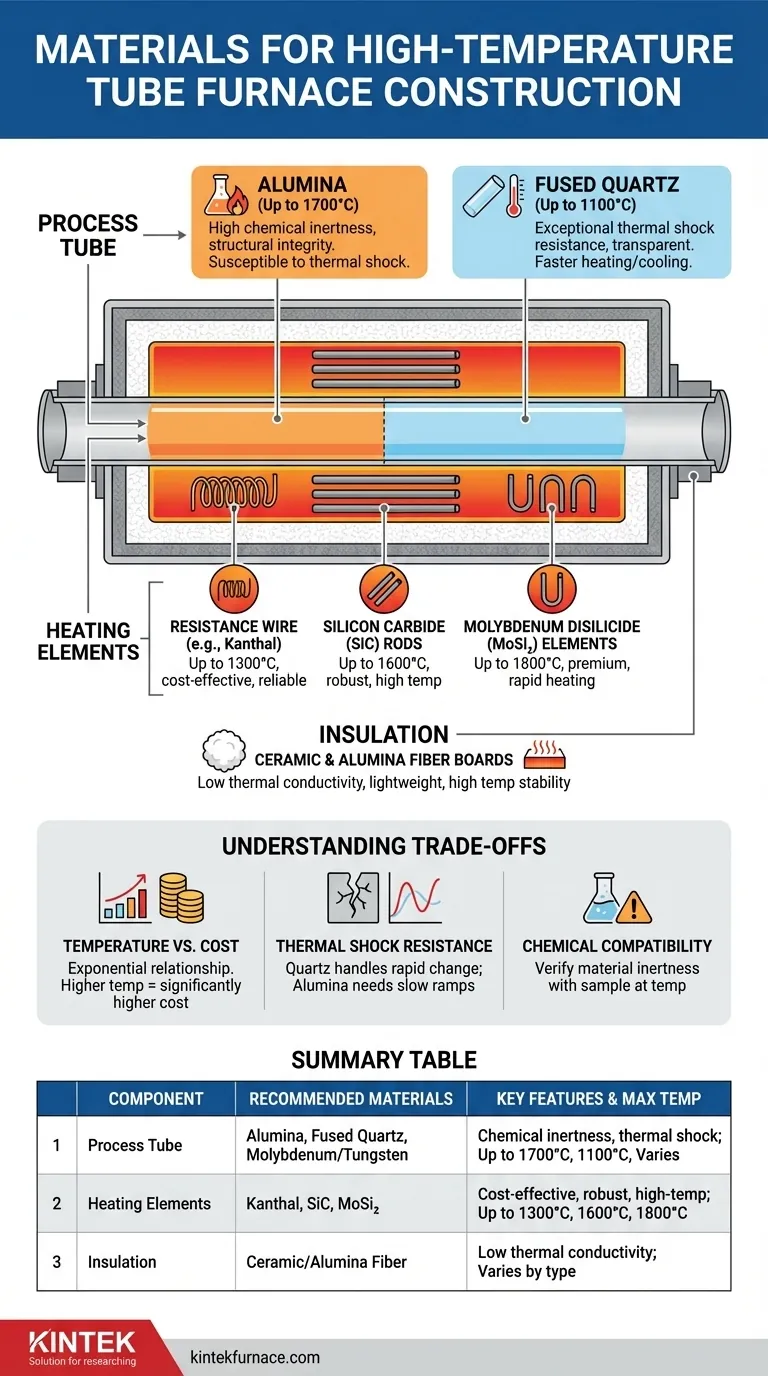

For constructing a high-temperature tube furnace, the primary materials depend on your target temperature and chemical environment. For the process tube itself, high-purity alumina is the standard for temperatures up to 1700°C, while fused quartz is excellent for applications up to 1100°C. The furnace body and insulation are best constructed from high-density alumina or ceramic fiber for its low thermal conductivity and high-temperature resistance.

Building a furnace is a system design challenge. The optimal materials are not a single choice, but a matched set of components—the process tube for containment, the insulation for efficiency, and the heating elements for generating heat—each selected to meet the specific temperature and chemical demands of your application.

The Core Component: The Process Tube

The process tube is the heart of the furnace, containing the sample and process atmosphere. Its material is the most critical choice, directly dictating the furnace's operational limits.

Alumina (Al₂O₃): The High-Temperature Workhorse

High-purity alumina ceramic is the go-to material for temperatures above 1100°C, capable of reaching up to 1700°C or even higher depending on purity.

It offers excellent chemical inertness and structural integrity at extreme temperatures. However, it is more susceptible to thermal shock than quartz and can crack if heated or cooled too rapidly.

Fused Quartz: The Versatile Standard

For temperatures up to approximately 1100°C, fused quartz is an outstanding choice. Its primary advantage is its exceptional resistance to thermal shock, allowing for much faster heating and cooling rates than alumina.

Unlike opaque ceramics, its transparency can also be useful for visual monitoring of a process. Note that Pyrex is not a suitable substitute, as it will soften and deform at these temperatures.

Specialized Metal Tubes: For Corrosive Environments

In specific cases where the process involves materials that would corrode ceramics, specialized metal tubes are required.

Tubes made of molybdenum or tungsten can be used for their high melting points and resistance to certain corrosive agents, but they must be operated in a vacuum or inert atmosphere to prevent their own oxidation.

The Heart of the Furnace: Heating Elements

Heating elements convert electrical energy into thermal energy. The material choice here directly defines the furnace's maximum achievable temperature.

Resistance Wire (e.g., Kanthal FeCrAl)

Iron-chromium-aluminum alloys like Kanthal are the most common and cost-effective heating elements. They are reliable for furnaces operating up to about 1300°C.

Silicon Carbide (SiC) Rods

For temperatures between 1300°C and 1600°C, silicon carbide rods are the industry standard. They are robust and offer a significant step up in temperature capability from resistance wire.

Molybdenum Disilicide (MoSi₂) Elements

Often called "silicon molybdenum rods," these U-shaped elements are the premium choice for the highest temperatures, operating reliably up to 1800°C. They allow for rapid heating but are more expensive and brittle than other options.

The Unsung Hero: Insulation

Effective insulation is what makes a furnace efficient and safe. Its job is to keep the heat inside the furnace cavity, reducing energy consumption and keeping the outer shell cool.

Ceramic & Alumina Fiber

Modern furnaces almost exclusively use rigid, high-density ceramic or alumina fiber boards. This material offers extremely low thermal conductivity, low weight, and excellent high-temperature stability.

It is easy to cut and shape, making it ideal for creating a highly efficient, layered insulation structure.

Understanding the Trade-offs

Selecting materials is a balancing act. Understanding the inherent compromises is key to designing a furnace that is both effective and economical.

Temperature vs. Cost

The relationship between maximum temperature and cost is exponential. A 1200°C furnace using a quartz tube and Kanthal wire is relatively inexpensive. A 1700°C furnace requiring a high-purity alumina tube and MoSi₂ elements will cost many times more.

Thermal Shock Resistance

This is a critical operational parameter. Quartz can withstand rapid temperature changes, while alumina requires slow, controlled heating and cooling ramps to prevent cracking. The operational time saved by using quartz can be a significant factor.

Chemical Compatibility

The process tube material must be inert to your sample and any process gases at temperature. What is inert at room temperature may become highly reactive at 1500°C. Always verify the compatibility of your process materials with the chosen tube material.

Making the Right Choice for Your Goal

Base your material selection on the most demanding aspect of your intended application.

- If your primary focus is general-purpose use up to 1100°C: Choose a fused quartz tube with Kanthal wire elements and standard ceramic fiber insulation for the best balance of performance, cost, and operational flexibility.

- If your primary focus is high-temperature processing (up to 1700°C): You must use a high-purity alumina tube, molybdenum disilicide (MoSi₂) heating elements, and high-alumina fiber insulation.

- If your primary focus is working with specific corrosive materials: Begin by identifying a compatible tube material, such as alumina or a specialized metal like molybdenum, and then build the rest of the furnace system around its temperature limits.

A systematic approach to selecting each component is the foundation for building a safe, reliable, and effective high-temperature furnace.

Summary Table:

| Component | Recommended Materials | Key Features | Max Temperature |

|---|---|---|---|

| Process Tube | Alumina, Fused Quartz, Molybdenum/Tungsten | Excellent chemical inertness, thermal shock resistance | Up to 1700°C, 1100°C, Varies |

| Heating Elements | Kanthal, Silicon Carbide, Molybdenum Disilicide | Cost-effective, robust, high-temperature capability | Up to 1300°C, 1600°C, 1800°C |

| Insulation | Ceramic/Alumina Fiber | Low thermal conductivity, high-temperature stability | Varies by type |

Need a custom high-temperature furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can support your lab's goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide