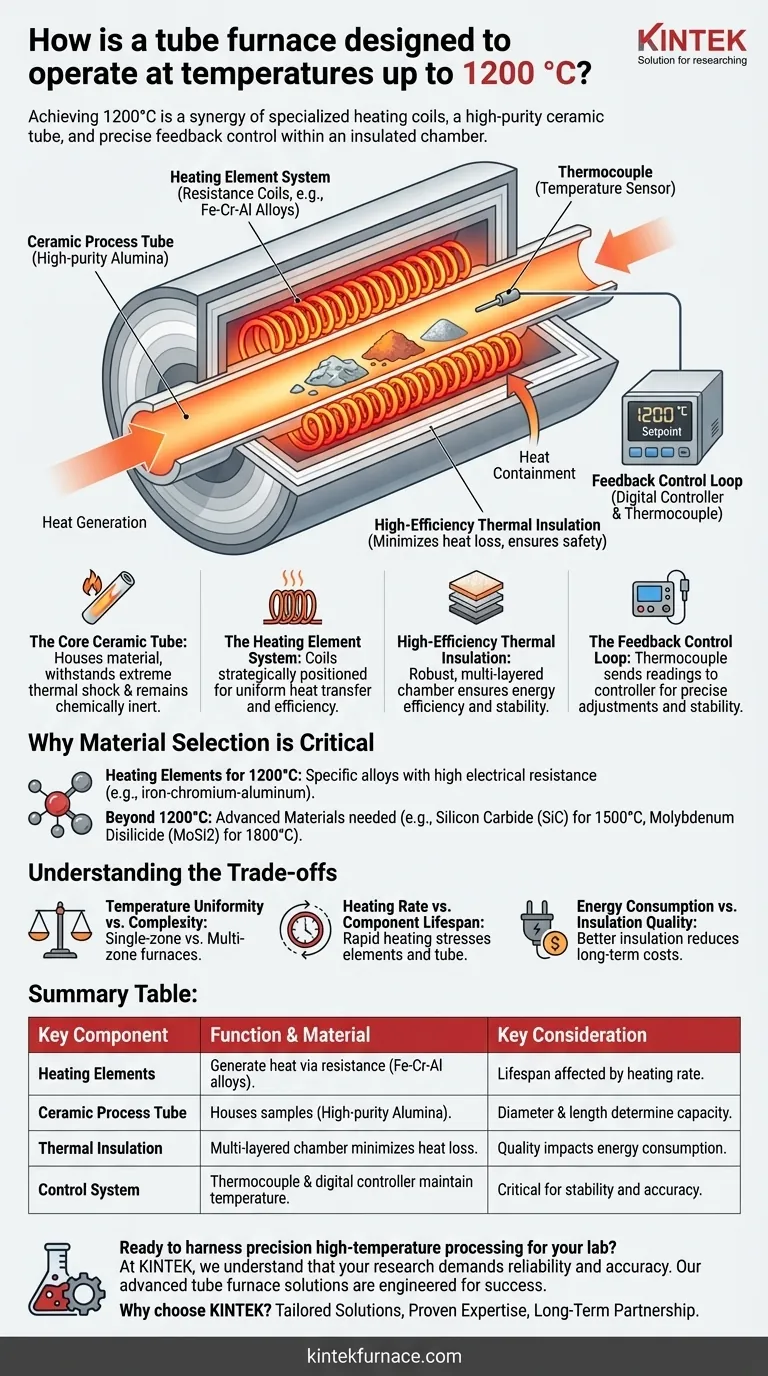

To operate at temperatures up to 1200°C, a tube furnace relies on a carefully engineered system of specialized heating coils, a high-purity ceramic process tube, and a precise feedback control mechanism. The heating elements, typically wound as a spring, are embedded around the ceramic tube within a highly insulated chamber to generate and contain the intense heat required.

The key to achieving and maintaining 1200°C is not one single component, but the synergy between the heating elements that generate the energy, the insulation that contains it, and the control system that constantly measures and adjusts it with precision.

The Anatomy of a 1200°C Furnace

A high-temperature tube furnace is a system where each part serves a critical function. Understanding these components reveals how such a stable and extreme environment is created.

The Core Ceramic Tube

The central component is the cylindrical tube that houses the material being processed. This tube is typically made from high-purity alumina or a similar ceramic because these materials can withstand extreme thermal shock and remain chemically inert at 1200°C.

The Heating Element System

For temperatures in the 1200°C range, the heat is generated by resistance heating coils. These elements are strategically positioned around the exterior of the ceramic tube, often embedded as a spring, to ensure a uniform temperature profile along the tube's length. This design maximizes the surface area for efficient radiant heat transfer.

High-Efficiency Thermal Insulation

The entire heating element and tube assembly is enclosed within a robust, multi-layered insulated chamber. This insulation is critical for minimizing heat loss, which ensures energy efficiency and maintains temperature stability. It also keeps the furnace's exterior structure at a safe temperature for operators.

The Feedback Control Loop

Achieving a precise temperature is impossible without control. A thermocouple, a sensitive temperature sensor, is placed near the heating elements. It constantly sends temperature readings to a digital controller, which then adjusts the power supplied to the heating elements to maintain the exact setpoint without overshooting.

Why Material Selection is Critical

The ability to reach 1200°C is fundamentally a challenge of material science. The components used are selected specifically for their ability to perform under extreme thermal stress.

Heating Elements for 1200°C

The coiled heating elements are made from specific alloys (like iron-chromium-aluminum) that have high electrical resistance and can operate continuously at these temperatures without degrading quickly.

Beyond 1200°C: The Need for Advanced Materials

The 1200°C limit is often defined by these coiled wire elements. To reach higher temperatures, different materials are required. Furnaces operating up to 1500°C use silicon carbide (SiC) rods, while those reaching 1800°C require advanced elements made of molybdenum disilicide (MoSi2).

Understanding the Trade-offs

Designing a furnace for high-temperature operation involves balancing competing factors. Recognizing these trade-offs is key to understanding its performance.

Temperature Uniformity vs. Complexity

A simple, single-zone furnace is cost-effective but may have slight temperature variations across the length of the tube. For applications requiring exceptional uniformity, more complex and expensive multi-zone furnaces are used, which have separate heating coils and control loops for different sections of the tube.

Heating Rate vs. Component Lifespan

While a furnace can be programmed for rapid heating, aggressive temperature ramps place significant stress on both the heating elements and the ceramic tube. A more measured heating rate can substantially extend the operational life of these critical components.

Energy Consumption vs. Insulation Quality

The amount of power required to maintain 1200°C is significant. The quality and thickness of the thermal insulation directly impact energy consumption and, therefore, the long-term operational cost of the furnace.

Making the Right Choice for Your Goal

The optimal furnace design depends entirely on its intended application.

- If your primary focus is precise material synthesis: The stability and accuracy of the temperature control system are the most critical features.

- If your primary focus is high throughput or processing larger samples: The diameter and length of the ceramic tube, along with the uniformity of the hot zone, are your key considerations.

- If your primary focus is experimental flexibility: A furnace designed for both horizontal and vertical operation provides the versatility needed for a wider range of tests.

By understanding these core design principles, you can effectively evaluate and utilize a tube furnace as a precision instrument for your specific high-temperature application.

Summary Table:

| Key Component | Function & Material | Key Consideration |

|---|---|---|

| Heating Elements | Generate heat via resistance (e.g., iron-chromium-aluminum alloys). | Lifespan is affected by heating rate; aggressive ramps cause stress. |

| Ceramic Process Tube | Houses samples; made from high-purity alumina for thermal shock resistance. | Diameter and length determine sample size and throughput capacity. |

| Thermal Insulation | Multi-layered chamber minimizes heat loss for efficiency and safety. | Quality impacts energy consumption and operational cost. |

| Control System | Thermocouple and digital controller maintain precise setpoint temperature. | Critical for applications requiring stability and accuracy, like material synthesis. |

Ready to harness precision high-temperature processing for your lab?

At KINTEK, we understand that your research demands reliability and accuracy at extreme temperatures. Our advanced tube furnace solutions are engineered with the same principles discussed here—superior heating elements, robust insulation, and exacting control—to ensure your experiments succeed.

Why choose KINTEK for your high-temperature needs?

- Tailored Solutions: Leveraging exceptional R&D and in-house manufacturing, we offer deep customization for your unique requirements, from standard Muffle and Tube Furnaces to complex Vacuum & Atmosphere systems and CVD/PECVD setups.

- Proven Expertise: Whether your focus is material synthesis, high-throughput processing, or experimental flexibility, we provide the precise temperature control and uniform heating your application demands.

- Long-Term Partnership: We design for durability and efficiency, helping you optimize heating rates and insulation to extend equipment lifespan and reduce operational costs.

Let's engineer the perfect high-temperature solution for your lab. Contact our experts today to discuss your specific needs and how our customized furnace systems can drive your innovations forward.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety