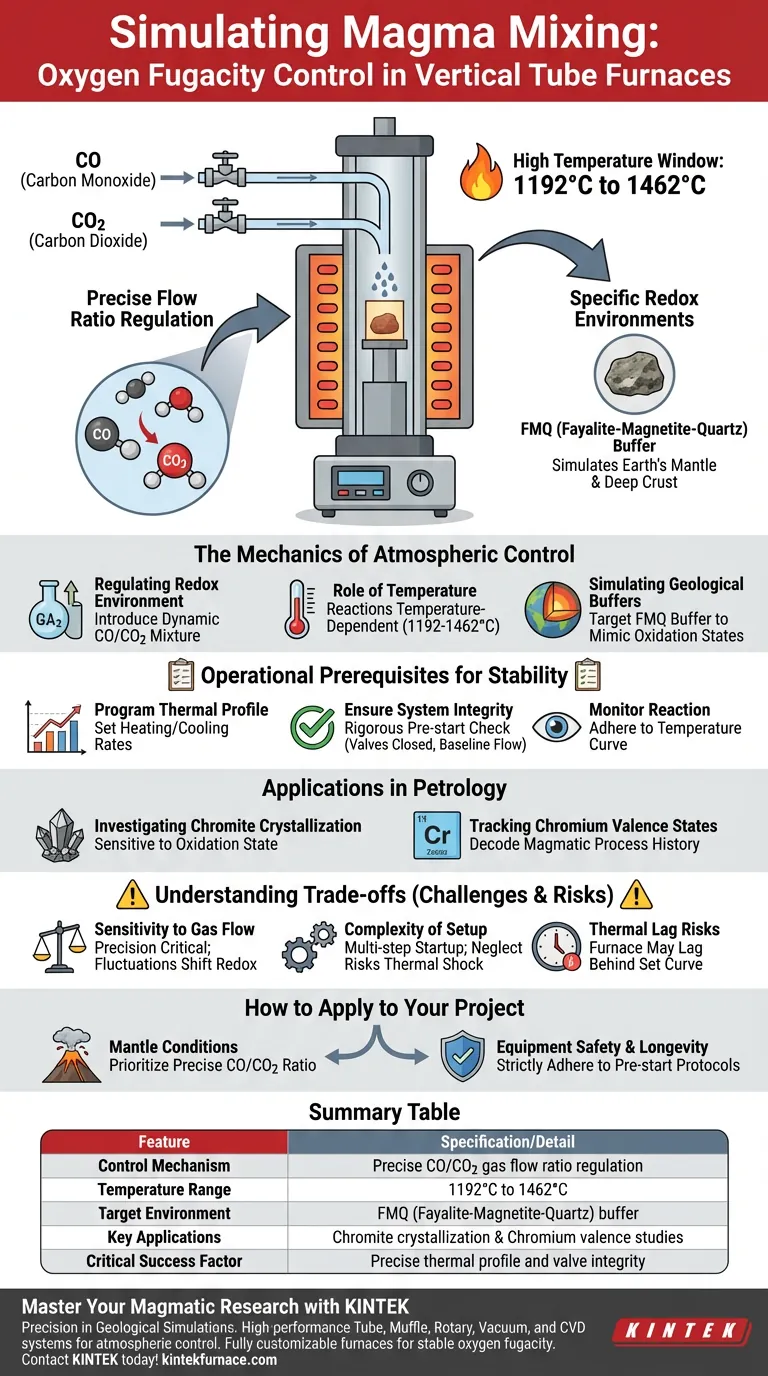

Precise control of oxygen fugacity is achieved by strictly regulating the flow ratio of carbon monoxide (CO) and carbon dioxide (CO2) within the furnace chamber. By adjusting these gas mixtures while maintaining high temperatures between 1192°C and 1462°C, the system creates specific redox environments—such as the fayalite-magnetite-quartz (FMQ) buffer—that are necessary to simulate the chemical conditions of magma mixing.

This equipment functions as a core platform for replicating the Earth's mantle and deep crust environments. By combining thermal precision with atmospheric control, it enables the detailed study of chromite crystallization and chromium valence state transitions under realistic magmatic conditions.

The Mechanics of Atmospheric Control

Regulating the Redox Environment

The core function of the vertical tube gas mixing furnace is to move beyond simple heating and control the chemical potential of oxygen. This is done by introducing a dynamic mixture of carbon monoxide (CO) and carbon dioxide (CO2).

The Role of Temperature

The interaction between these gases and the sample is highly temperature-dependent. The furnace operates within a specific high-temperature window, ranging from 1192°C to 1462°C, to facilitate these reactions.

Simulating Geological Buffers

By tuning the gas ratios at these temperatures, researchers can lock the environment to known geological standards. The most common target is the FMQ (fayalite-magnetite-quartz) buffer, which mimics the oxidation state found in the Earth's upper mantle and deep crust.

Operational Prerequisites for Stability

Programming the Thermal Profile

Before any gas mixing occurs, the thermodynamic foundation must be set. You must program a precise temperature curve that dictates specific heating and cooling rates suited for the experiment.

Ensuring System Integrity

A rigorous pre-start check is essential to prevent atmospheric contamination. All valves must be confirmed closed, and the baseline gas flow must be verified as normal before the heating cycle begins.

Monitoring the Reaction

Once the main power is engaged and the program starts, active monitoring is required. You must ensure the actual furnace temperature strictly adheres to the set curve to maintain the validity of the oxygen fugacity calculations.

Applications in Petrology

Investigating Chromite Crystallization

The precise control of oxygen fugacity is particularly critical for studying chromite. The crystallization behavior of this mineral is sensitive to the oxidation state of the magma.

Tracking Chromium Valence States

The furnace allows scientists to observe transitions in chromium valence states. This data helps decode the history of magmatic processes and the conditions under which specific minerals formed deep underground.

Understanding the Trade-offs

Sensitivity to Gas Flow Variations

The accuracy of the oxygen fugacity is entirely dependent on the precision of the gas flow ratio. Even minor fluctuations in the CO/CO2 mix can shift the redox environment away from the target FMQ buffer, invalidating the simulation.

Complexity of Setup

Unlike standard air furnaces, this system requires a multi-step startup procedure. Neglecting the pre-start checks or the temperature programming can lead to thermal shock or an uncontrolled atmosphere, ruining the sample.

Thermal Lag Risks

While the controller sets a curve, the physical furnace may experience lag. If the temperature monitoring is not vigilant, the sample may not experience the exact temperature-fugacity combination intended for the simulation.

How to Apply This to Your Project

To ensure your simulation yields valid petrological data, align your operational procedures with your specific experimental goals:

- If your primary focus is simulating Mantle Conditions: Prioritize the precise calculation and maintenance of the CO/CO2 ratio to lock the environment to the FMQ buffer.

- If your primary focus is Equipment Safety and Longevity: Strictly adhere to the pre-start check protocols and verify all valves and flow rates before engaging the main power.

Mastering the interplay between gas ratios and temperature profiles is the key to unlocking accurate data on magmatic evolution.

Summary Table:

| Feature | Specification / Detail |

|---|---|

| Control Mechanism | Precise CO/CO2 gas flow ratio regulation |

| Temperature Range | 1192°C to 1462°C |

| Target Environment | FMQ (Fayalite-Magnetite-Quartz) buffer |

| Key Applications | Chromite crystallization & Chromium valence studies |

| Critical Success Factor | Precise thermal profile and valve integrity |

Master Your Magmatic Research with KINTEK

Precision is non-negotiable in geological simulations. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems specifically engineered for complex atmospheric control.

Our lab high-temperature furnaces are fully customizable to meet your unique experimental needs, ensuring stable oxygen fugacity and thermal precision for every sample. Contact us today to find the perfect furnace solution for your lab!

Visual Guide

References

- Erin Keltie, James M. Brenan. Experiments and Models Bearing on the Role of Magma Mixing and Contamination on Chromite Crystallization in Ultramafic Magmas. DOI: 10.1093/petrology/egaf076

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What factors should be considered when purchasing an alumina tube furnace? Key Tips for High-Temp Precision

- What are the functions of a quartz tube fixed-bed reactor? Ensure Precision in Catalyst Evaluation

- How does a vacuum tube nitriding system control the reaction environment? Precision Surface Hardening for AISI 304

- Why is a high-temperature tube furnace utilized for the calcination of nano-zinc oxide? Master Microstructure Control

- What is the intended use of the 3-Zone tube furnace? Achieve Precise Thermal Control for Advanced Materials

- Why is a high-precision tube furnace necessary for YIG thin films? Unlock Superior Magnetic Performance

- Why is it critical to precisely control the heating rate at 3°C/min for Ni/NiO@GF electrodes? Achieve Structural Integrity

- Can a quartz tube furnace be used for melting materials? Unlock Precise Melting with Visual Control