At its core, a 3-zone tube furnace is designed for high-precision thermal processes like flexible annealing and chemical vapor deposition (CVD) at temperatures typically below 1000°C. Its multi-zone configuration is engineered to create a highly uniform or specifically profiled temperature environment that is superior to what a single-zone furnace can achieve.

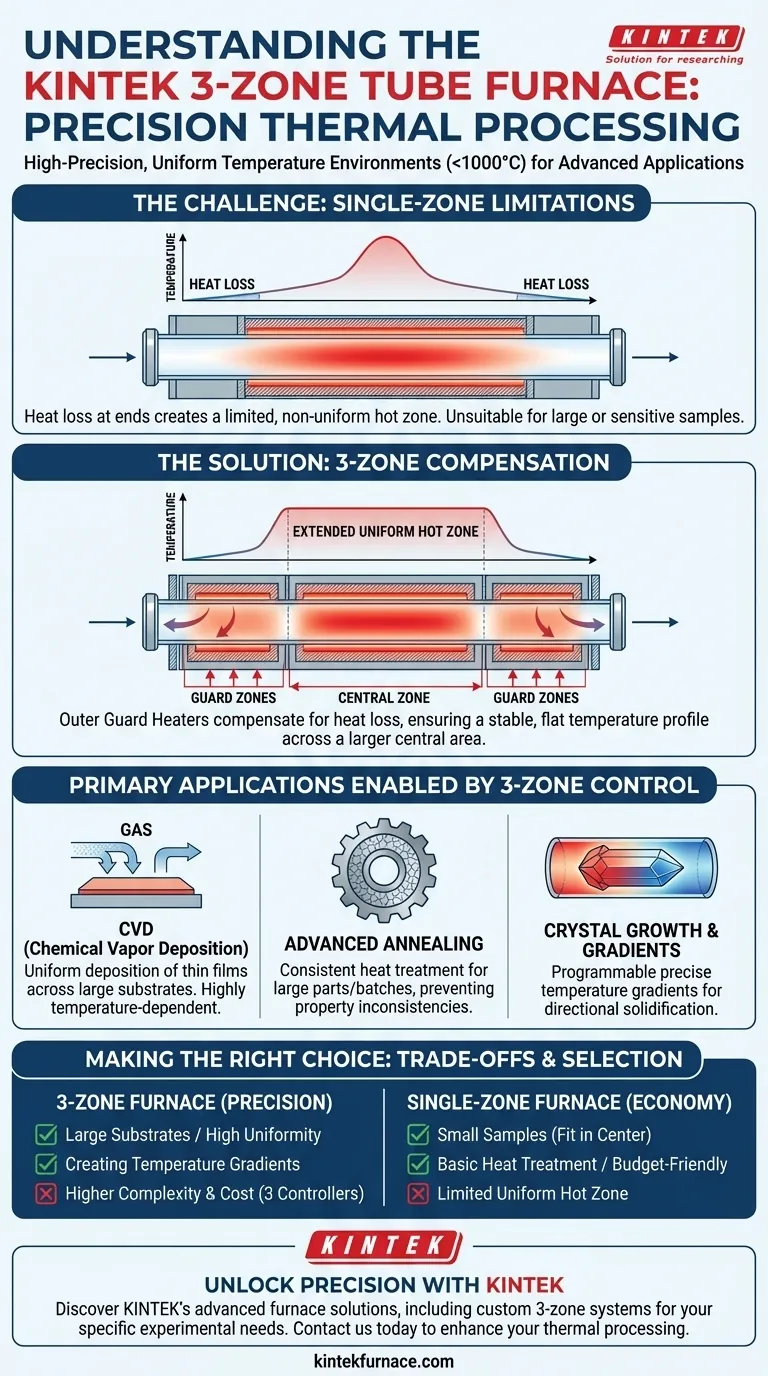

The central challenge in any tube furnace is heat loss at the ends of the tube. A 3-zone furnace solves this by using two outer "guard" zones to compensate for this loss, ensuring the large central zone maintains an exceptionally stable and uniform temperature.

The Fundamental Problem: Achieving True Thermal Uniformity

Any heating process that requires consistency across a sample, from creating semiconductor films to annealing metal parts, depends on thermal uniformity. A 3-zone furnace is specifically designed to master this challenge.

Why Single-Zone Furnaces Have Limits

In a standard single-zone furnace, the temperature is highest in the very center and naturally drops off toward the cooler, open ends of the tube. This heat loss phenomenon shrinks the effective "hot zone" where the temperature is stable and accurate. For large samples or sensitive processes, this limited uniform area is a significant drawback.

The 3-Zone Solution: Compensating for Heat Loss

A 3-zone furnace divides the heating element into three independently controlled sections: a large central zone and two smaller zones at each end.

The outer zones act as guard heaters. By setting them to a slightly higher temperature, you can create thermal barriers that prevent heat from escaping the central zone. This effectively cancels out the natural temperature drop-off.

The Result: A Longer, Flatter Hot Zone

This compensation creates a much longer, flatter, and more stable temperature profile across the central zone. This allows you to process larger samples or run processes that are highly sensitive to temperature variations with much greater reliability.

Primary Applications Enabled by 3-Zone Control

The precise control offered by a 3-zone architecture makes it ideal for advanced material synthesis and treatment.

Chemical Vapor Deposition (CVD)

In CVD, precursor gases flow through the tube and react on a heated substrate to form a thin film. The rate of this reaction and the quality of the resulting film are extremely dependent on temperature. A 3-zone furnace's uniform hot zone ensures the film is deposited evenly across the entire substrate.

Advanced Annealing

Annealing modifies the microstructure of a material to improve its properties. When annealing large components or batches of smaller parts, a uniform temperature ensures every part of the material receives the exact same heat treatment. This prevents inconsistencies in hardness, ductility, or electrical properties.

Crystal Growth and Gradient Freezing

A 3-zone furnace can also be programmed to create a precise temperature gradient by setting each zone to a different target temperature. This is essential for directional solidification and certain types of crystal growth, such as physical vapor transport, where material evaporates in a hot zone and condenses in a cooler zone.

Understanding the Trade-offs

While powerful, a 3-zone furnace is not always the necessary choice. Understanding its trade-offs is key to making a sound investment.

Increased Complexity and Cost

A 3-zone furnace requires three separate temperature controllers and thermocouples. This added hardware and control logic makes it inherently more complex and expensive than a comparable single-zone model.

When a Single Zone is Sufficient

For processing very small samples that fit comfortably within the naturally uniform hot zone of a single-zone furnace, the added expense and complexity of a 3-zone system may be unnecessary.

Horizontal vs. Other Configurations

This design is distinct from other furnace types. Vertical furnaces are better for processes involving quenching or dropping samples, while rotary furnaces are built for the continuous processing of powders and loose materials. The horizontal 3-zone furnace is purpose-built for batch processing of substrates or parts requiring a static, controlled atmosphere.

Making the Right Choice for Your Process

Your specific application dictates whether the precision of a 3-zone furnace is a requirement or an unnecessary expense.

- If your primary focus is processing large substrates or ensuring maximum thermal uniformity for processes like CVD: A 3-zone furnace is the superior choice for creating a long, stable hot zone.

- If your primary focus is growing crystals or creating specific temperature gradients: The independent control of a 3-zone furnace provides the necessary flexibility to engineer a precise thermal profile.

- If your primary focus is processing small samples, conducting basic heat treatment, or managing a tight budget: A single-zone furnace is often a more economical and perfectly adequate solution.

Ultimately, choosing the right furnace comes down to matching the tool's capabilities to your specific process requirements.

Summary Table:

| Feature | Description |

|---|---|

| Primary Use | High-precision thermal processes like annealing and CVD at temperatures below 1000°C |

| Key Advantage | Creates a uniform or profiled temperature zone by compensating for heat loss with guard heaters |

| Ideal Applications | Chemical Vapor Deposition (CVD), advanced annealing, crystal growth, and gradient freezing |

| Considerations | More complex and costly than single-zone furnaces; best for large samples or sensitive processes |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need the uniform heating of a 3-zone tube furnace for CVD or tailored systems for other processes, we deliver reliability and performance.

Contact us today to discuss how our expertise can enhance your thermal processing—Get in touch now!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation