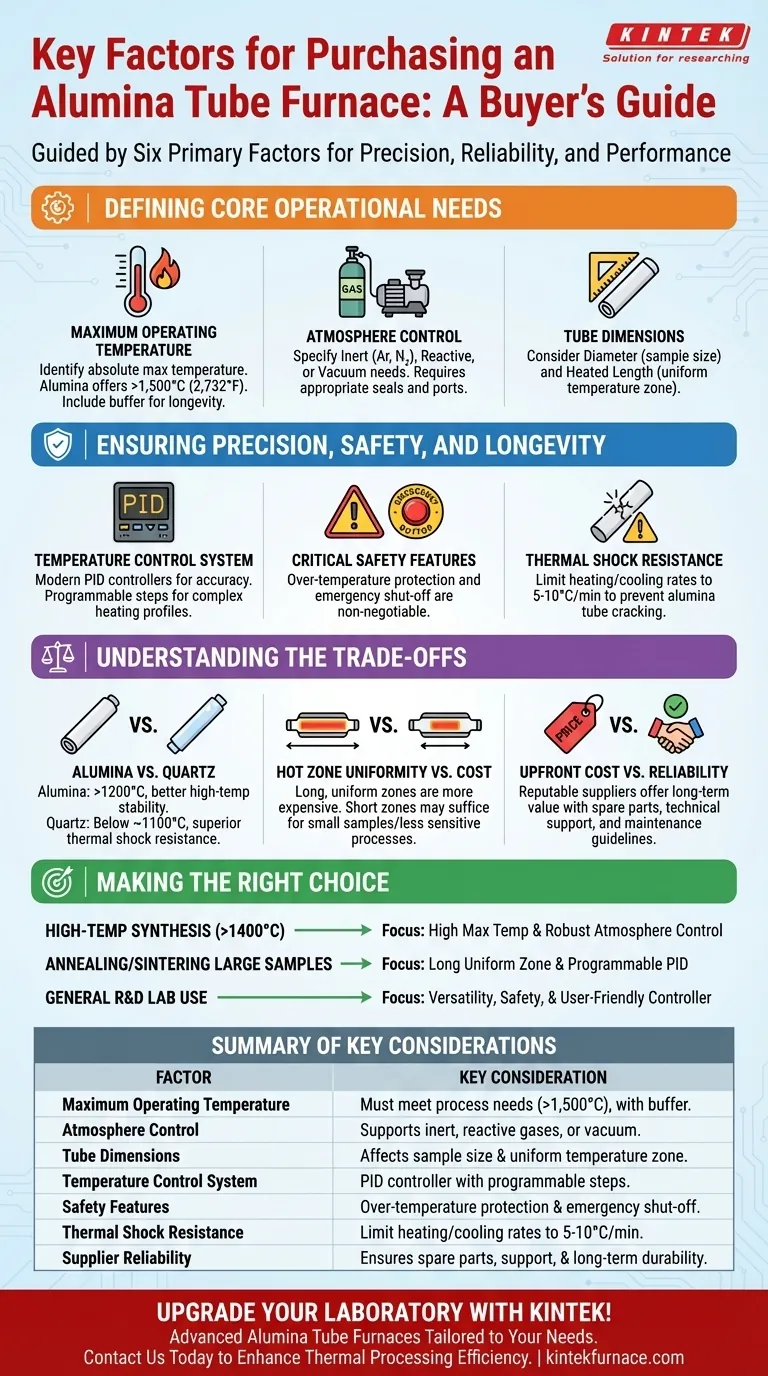

When purchasing an alumina tube furnace, your decision must be guided by six primary factors. These are the maximum operating temperature required, the need for a controlled atmosphere (gas or vacuum), the physical size of the tube, the precision of the temperature control system, essential safety features, and the long-term reliability of the supplier.

An alumina tube furnace is a precise instrument for advanced thermal processing. The goal is not simply to buy a heater, but to acquire a system whose performance characteristics—temperature, atmosphere, and control—perfectly match the demands of your specific scientific or industrial application, ensuring repeatable and reliable results.

Defining Your Core Operational Needs

Before evaluating any model, you must first define the absolute requirements of your process. These three factors will immediately narrow your options.

Maximum Operating Temperature

The primary function of a furnace is to reach and hold a specific temperature. Alumina (Aluminum Oxide, Al₂O₃) is chosen for its excellent stability at very high temperatures, often exceeding 1,500°C (2,732°F).

You must identify the absolute maximum temperature your process requires and then select a furnace rated for at least that temperature, ideally with a small buffer. A furnace consistently run at its absolute limit will have a shorter lifespan.

Atmosphere Control (Vacuum or Gas)

Many high-temperature processes cannot be performed in ambient air due to oxidation. An alumina tube is chemically inert, making it ideal for creating a controlled environment.

Consider if your application requires:

- Inert Atmosphere: Flowing gases like Argon or Nitrogen to prevent reactions.

- Reactive Atmosphere: Introducing specific gases to participate in the process.

- Vacuum: Removing atmosphere to prevent contamination or for specific processes like degassing.

The furnace system must be equipped with the appropriate gas-tight seals, flanges, and ports to support your atmospheric needs.

Tube Dimensions and Sample Capacity

The furnace's tube dictates your working volume. You must consider both the diameter and the length of the tube.

The diameter limits the size of your sample or crucible. The length, specifically the "heated length," determines the size of the uniform temperature zone. For processes requiring consistent temperature across the entire sample, a longer heated zone is critical.

Ensuring Precision, Safety, and Longevity

Once core needs are met, the focus shifts to the quality and reliability of the furnace system. These features separate a basic heater from a scientific instrument.

The Temperature Control System

Modern furnaces use a PID (Proportional-Integral-Derivative) controller to manage temperature. This system ensures accuracy and stability.

Look for a controller that offers programmable steps. This allows you to define complex heating profiles with multiple ramps (rate of temperature change) and dwells (holding at a set temperature), which is essential for most advanced materials processing.

Critical Safety Features

A high-temperature furnace is a significant potential hazard. Non-negotiable safety features include over-temperature protection, which automatically shuts down the furnace if it exceeds a set safety limit.

An emergency shut-off button should also be clearly visible and accessible. These features protect both the operator and the instrument from catastrophic failure.

Thermal Shock Resistance and Heating Rates

Alumina is exceptionally strong at high temperatures but can be brittle and is highly susceptible to thermal shock—cracking caused by rapid temperature changes.

The furnace's controller must be able to limit the heating and cooling rates. As a rule, rates for alumina tubes should not exceed 10°C per minute, and a slower rate of 5-8°C/min is often recommended to maximize the tube's lifespan.

Understanding the Trade-offs

Selecting the right furnace involves balancing performance, longevity, and cost. Understanding these trade-offs is key to making an informed investment.

Alumina vs. Other Materials

While alumina is excellent for very high temperatures (>1200°C), it is not the only option. For processes below ~1100°C, a quartz tube may be a better choice.

Quartz offers superior thermal shock resistance, allowing for much faster heating and cooling cycles. However, it cannot withstand the extreme temperatures that alumina can.

Uniform Hot Zone vs. Cost

A furnace with a longer, more uniform hot zone will be more expensive. This is because it requires more heating elements and more sophisticated control.

If your process involves small samples or is less sensitive to minor temperature variations, you may be able to use a furnace with a shorter heated length, reducing upfront cost.

Upfront Cost vs. Long-Term Reliability

Choosing a reputable supplier with a track record of quality and support is critical. A cheaper furnace from an unknown brand may save money initially but can lead to higher long-term costs.

Consider factors like the availability of spare parts (especially heating elements and tubes), the quality of technical support, and the clarity of the maintenance guidelines. A reliable furnace is one that is well-supported.

Making the Right Choice for Your Application

Your final choice should be a direct reflection of your primary goal.

- If your primary focus is high-temperature material synthesis (>1400°C): Prioritize a furnace with a high maximum temperature rating and robust atmosphere control capabilities.

- If your primary focus is annealing or sintering large samples: Prioritize a long, uniform heated zone and a programmable PID controller for precise thermal profiles.

- If your primary focus is general R&D lab use: Prioritize versatility, strong safety features, and a user-friendly controller from a reputable supplier.

By carefully matching the furnace's capabilities to your specific process requirements, you make an investment that will yield accurate and reliable results for years to come.

Summary Table:

| Factor | Key Consideration |

|---|---|

| Maximum Operating Temperature | Must meet process needs, often >1,500°C, with buffer for longevity |

| Atmosphere Control | Supports inert, reactive gases, or vacuum for oxidation prevention |

| Tube Dimensions | Diameter and heated length affect sample size and uniform temperature zone |

| Temperature Control System | PID controller with programmable steps for accuracy and stability |

| Safety Features | Over-temperature protection and emergency shut-off for hazard prevention |

| Thermal Shock Resistance | Limit heating/cooling rates to 5-10°C/min to avoid cracking |

| Supplier Reliability | Ensures spare parts, support, and long-term durability |

Upgrade your laboratory with precision high-temperature solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced alumina tube furnaces tailored to your unique experimental needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization capabilities. Whether you're in material synthesis, annealing, or R&D, KINTEK ensures reliable performance and expert support. Contact us today to discuss how we can enhance your thermal processing efficiency and achieve superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis