The maximum temperature for a three-zone split tube furnace depends on the specific model, as they are built with different heating elements to achieve distinct thermal ranges. Each of the three zones will have the same maximum capability, which is typically 1200°C, 1400°C, or 1700°C. It is crucial, however, to distinguish this absolute maximum from the lower continuous operating temperature, which is the sustainable limit for reliable, long-term use.

The key takeaway is not the single maximum temperature, but understanding that this rating reflects the furnace's heating element material. This choice dictates the furnace's cost, operational lifespan, and suitability for specific processes like annealing, crystal growth, or chemical vapor deposition (CVD).

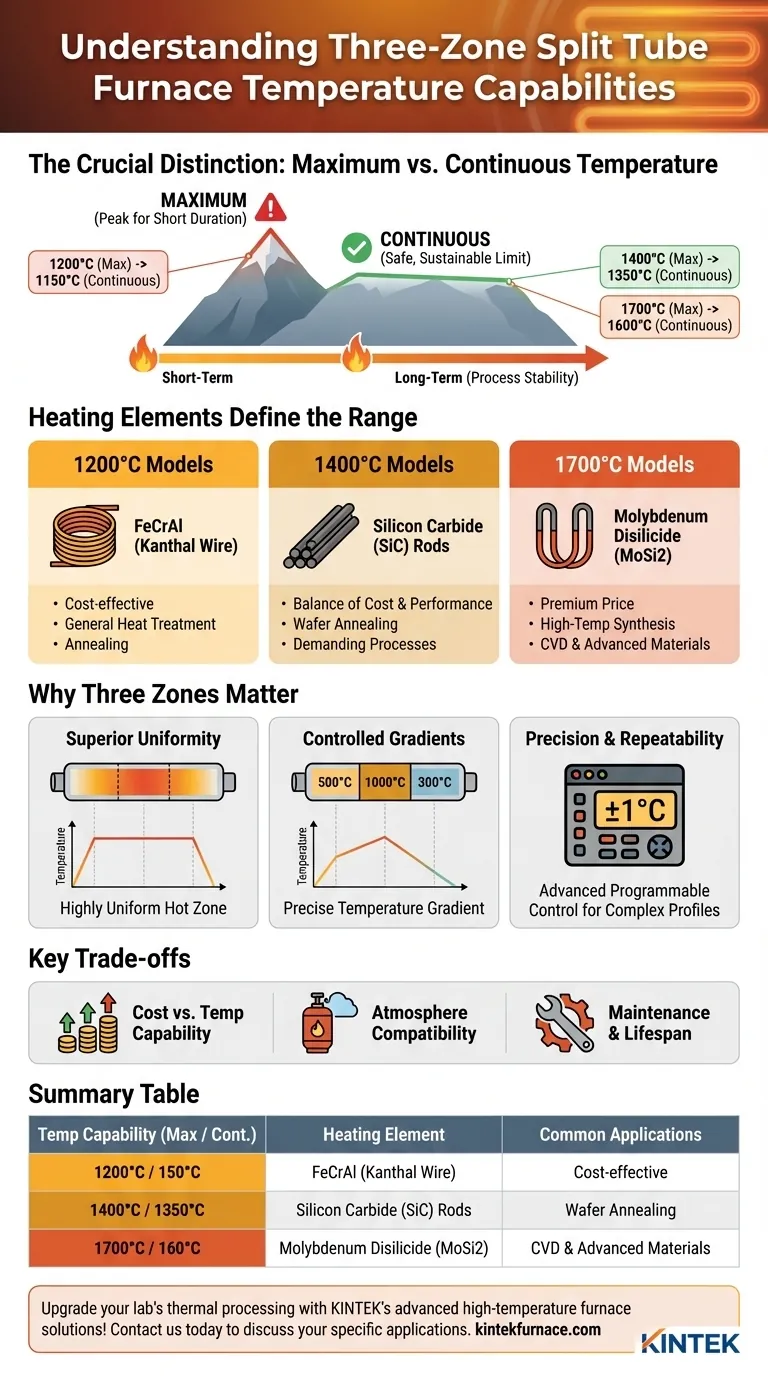

Understanding Maximum vs. Continuous Temperature

Choosing a furnace requires looking beyond the peak temperature rating. The distinction between maximum and continuous operating temperature is the most critical factor for ensuring equipment longevity and process repeatability.

The Meaning of Maximum Temperature (1200°C / 1400°C / 1700°C)

The listed maximum temperatures are not settings on a single furnace. They represent different classes of furnaces. A furnace is designed and sold with one of these specific temperature limits.

This peak rating is the absolute highest temperature the furnace can reach for very short durations. Operating at this temperature continuously will significantly shorten the life of the heating elements and internal insulation.

The Critical Role of Continuous Operating Temperature (1150°C / 1350°C / 1600°C)

The continuous operating temperature is the safe, sustainable limit for running the furnace for extended periods. For a 1700°C-rated furnace, the continuous limit is typically around 1600°C.

Adhering to this lower rating is essential for process stability and preventing premature equipment failure. It is the most important number to consider when matching a furnace to your required process temperature.

How Heating Elements Define the Temperature Range

The furnace's temperature capability is dictated by the material used for its heating elements.

- 1200°C Models: Typically use Iron-Chrome-Aluminum (FeCrAl) alloy, often known as Kanthal wire. These are the most cost-effective option for general heat treatment and annealing.

- 1400°C Models: Typically use Silicon Carbide (SiC) rods. These offer a significant step up in temperature for more demanding processes while remaining a good balance of cost and performance.

- 1700°C Models: Use Molybdenum Disilicide (MoSi2) elements. These are required for high-temperature synthesis and advanced materials research but come at a premium price.

Why Three Zones Matter for Process Control

A three-zone configuration offers a significant advantage over single-zone furnaces by providing granular control over the thermal environment.

Achieving Superior Temperature Uniformity

A single-zone furnace is only truly uniform in a very small area at its absolute center. A three-zone furnace uses its end zones to compensate for heat loss at the tube's openings.

By setting all three zones to the same temperature, you can create a much longer, stable, and highly uniform hot zone across the length of the tube. This is vital for processing larger samples or multiple smaller samples consistently.

Creating Controlled Temperature Gradients

The true power of a three-zone furnace is the ability to set each zone to a different temperature. This allows you to create a precise temperature gradient along the tube.

This capability is essential for advanced processes like CVD, where you might need to pre-heat a gas in the first zone, have it react in the hot central zone, and begin a controlled cool-down in the third zone.

Precision and Repeatability

These furnaces are equipped with advanced programmable controllers that manage each zone independently. This allows for complex, multi-step thermal profiles to be executed with high precision (typically ±1°C) and repeatability, which is critical for scientific research and quality-controlled production.

Understanding the Trade-offs

Selecting the right furnace involves balancing performance needs with practical constraints.

Cost vs. Temperature Capability

The primary trade-off is cost. As the maximum temperature rating increases, the cost of the furnace and its replacement heating elements rises significantly. A 1700°C MoSi2 furnace can be several times more expensive than a 1200°C FeCrAl model.

Process Atmosphere and Element Compatibility

The type of gas atmosphere you use can affect the heating elements. For example, some elements degrade more quickly in reducing or reactive atmospheres. You must ensure the element material is compatible with your specific process gases.

Maintenance and Lifespan

Higher operating temperatures place more stress on all furnace components. Running a furnace consistently near its continuous limit will require more frequent inspection and eventual replacement of heating elements compared to running it at more moderate temperatures.

Making the Right Choice for Your Application

Your final decision should be guided by the specific thermal requirements of your process.

- If your primary focus is high-temperature synthesis (>1500°C): A 1700°C model with MoSi2 elements is necessary, but be prepared for the higher initial investment and maintenance costs.

- If your primary focus is uniform processing below 1350°C (e.g., wafer annealing): A 1400°C model with SiC elements offers an excellent balance of performance, uniform zone length, and cost.

- If your primary focus is general heat treatment below 1150°C: A 1200°C model with FeCrAl elements is the most cost-effective and reliable solution for your needs.

Ultimately, choosing the correct furnace is about precisely matching the equipment's capabilities to your scientific or production goals.

Summary Table:

| Temperature Capability | Heating Element | Common Applications |

|---|---|---|

| 1200°C (Max) / 1150°C (Continuous) | Iron-Chrome-Aluminum (FeCrAl) | General heat treatment, annealing |

| 1400°C (Max) / 1350°C (Continuous) | Silicon Carbide (SiC) | Wafer annealing, demanding processes |

| 1700°C (Max) / 1600°C (Continuous) | Molybdenum Disilicide (MoSi2) | High-temperature synthesis, CVD, advanced materials |

Upgrade your lab's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable, customizable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise matching to your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right High-Temp Solution