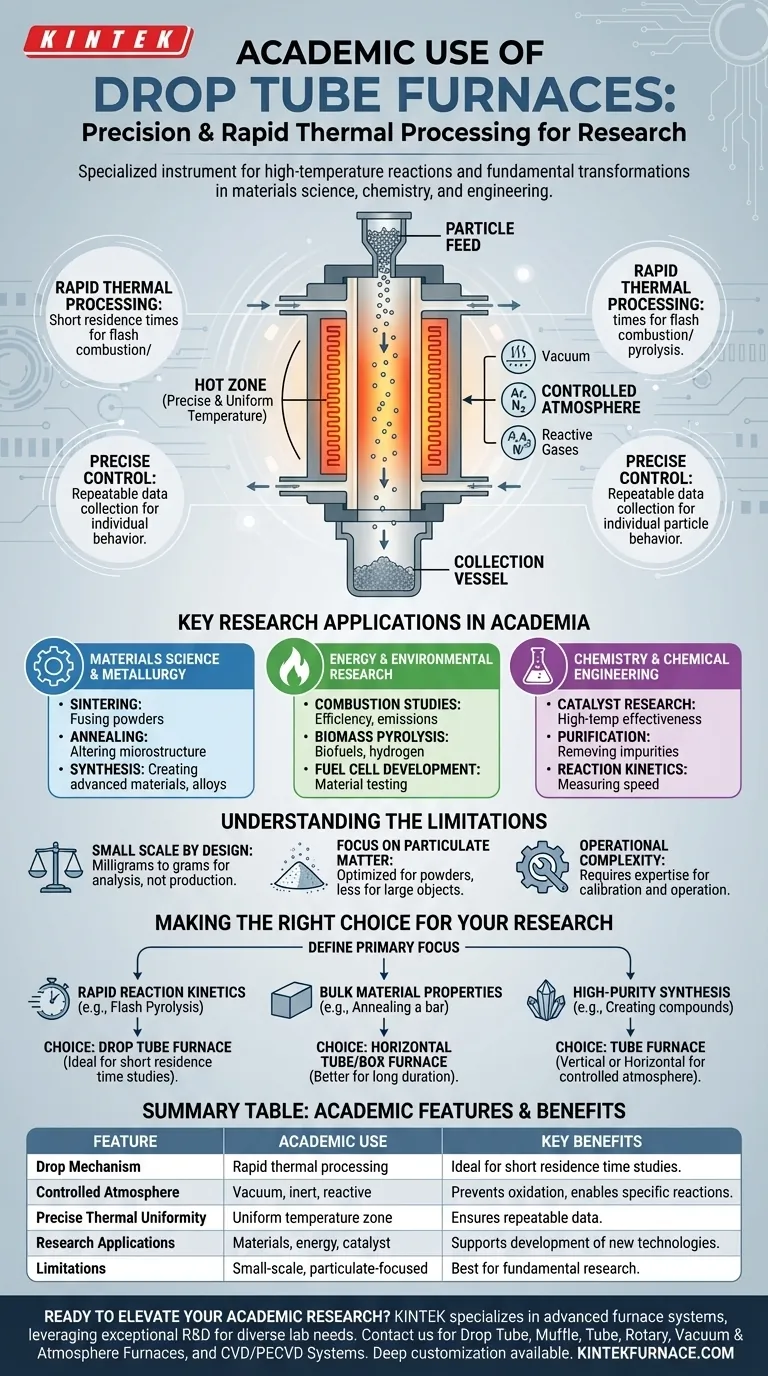

In an academic setting, a drop tube furnace is a specialized research and teaching instrument used primarily in materials science, chemistry, and engineering departments. It is designed to heat small quantities of material to very high, precisely controlled temperatures in a specific gaseous atmosphere, often for very short periods, allowing scientists to study fundamental transformations.

The core value of a drop tube furnace in academia is its ability to create a miniature, highly controlled environment for high-temperature reactions. This allows researchers to isolate and study the behavior of individual particles during processes like combustion or synthesis, providing data that is essential for developing new materials and energy technologies.

The Core Function: A Controlled Fall Through Fire

A drop tube furnace is a type of vertical tube furnace. Its unique design is central to its academic function, allowing researchers to observe processes that happen in fractions of a second.

The 'Drop' Mechanism

The defining feature is that material, typically in powder or particle form, is dropped from the top of a vertical, heated ceramic tube.

As the particles fall through the "hot zone," they undergo rapid thermal processing. This setup is ideal for studying phenomena with short residence times, such as flash combustion or pyrolysis.

Controlled Atmosphere

The sealed tube allows for complete control over the gaseous environment. Researchers can create a vacuum or introduce inert gases (like argon or nitrogen) to prevent oxidation.

Alternatively, they can introduce reactive gases to study specific chemical reactions, such as oxidation or reduction, under precise conditions.

Precise Thermal Uniformity

Academic research demands repeatability. Drop tube furnaces provide an exceptionally uniform and stable temperature zone.

This ensures that every particle passing through the furnace experiences the exact same thermal conditions, which is critical for collecting reliable and comparable data.

Key Research Applications in Academia

While used in teaching to demonstrate thermodynamic principles, the primary academic use of a drop tube furnace is for cutting-edge research.

Materials Science and Metallurgy

Researchers use these furnaces to investigate the creation and behavior of advanced materials. Key processes include:

- Sintering: Fusing ceramic or metal powders to form a solid mass.

- Annealing: Altering a material's microstructure to make it more ductile.

- Synthesis: Creating novel composites, alloys, or high-purity inorganic compounds.

These experiments help develop new materials with enhanced properties, such as greater strength or heat resistance.

Energy and Environmental Research

This is a major field for drop tube furnace applications. Scientists simulate industrial-scale processes on a manageable, observable level.

- Combustion Studies: Analyzing how single particles of coal or other fuels burn to improve efficiency and reduce emissions.

- Biomass Pyrolysis: Studying the thermal decomposition of organic matter (like wood chips) in an oxygen-free environment to produce biofuels and hydrogen.

- Fuel Cell Development: Testing the high-temperature performance and durability of materials used in solid oxide fuel cells.

Chemistry and Chemical Engineering

In chemistry, the furnace is a powerful tool for synthesis and analysis.

- Catalyst Research: Evaluating the effectiveness and longevity of catalysts at high operating temperatures.

- Purification: Removing impurities from compounds through processes like sublimation or calcination.

- Reaction Kinetics: Precisely measuring the speed of chemical reactions at high temperatures.

Understanding the Limitations

While powerful, the drop tube furnace is a specialized tool with specific trade-offs that are important to understand in an academic context.

Small Scale by Design

These furnaces are designed for analysis, not production. They process milligrams or grams of material, which is perfect for fundamental research but unsuitable for creating large quantities.

Focus on Particulate Matter

The "drop" design is optimized for powders, particles, or aerosols. It is less suited for heat-treating a single, large, solid object, where a horizontal tube furnace or a box furnace would be more appropriate.

Operational Complexity

Achieving a stable, uniform hot zone and a precisely controlled atmosphere requires significant expertise. These are not simple ovens; they are complex instruments that demand careful calibration and operation to yield valid scientific results.

Making the Right Choice for Your Research

The decision to use a drop tube furnace hinges on the specific scientific question you are trying to answer.

- If your primary focus is rapid reaction kinetics: A drop tube furnace is the ideal tool for studying how individual particles behave during processes with very short residence times, like flash pyrolysis.

- If your primary focus is bulk material properties: A standard horizontal tube or box furnace is better suited for long-duration processes like annealing a metal bar or growing a large single crystal.

- If your primary focus is high-purity synthesis: A tube furnace (either vertical or horizontal) is excellent for creating compounds in a highly controlled, non-contaminating atmosphere.

Ultimately, understanding the furnace's core capability—precise, rapid thermal processing of small particles—is the key to leveraging it for impactful academic discovery.

Summary Table:

| Feature | Academic Use | Key Benefits |

|---|---|---|

| Drop Mechanism | Rapid thermal processing of particles | Ideal for short residence time studies like combustion and pyrolysis |

| Controlled Atmosphere | Vacuum, inert, or reactive gas environments | Prevents oxidation, enables specific chemical reactions |

| Precise Thermal Uniformity | Uniform temperature zone in the hot zone | Ensures repeatable and reliable data collection |

| Research Applications | Materials synthesis, energy studies, catalyst research | Supports development of new materials and clean energy technologies |

| Limitations | Small-scale, particulate-focused, complex operation | Best for fundamental research, not bulk production |

Ready to elevate your academic research with precision high-temperature solutions? At KINTEK, we specialize in advanced furnace systems tailored for diverse laboratory needs. Leveraging exceptional R&D and in-house manufacturing, we offer products like Drop Tube, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Whether you're in materials science, energy, or chemistry, our expertise ensures reliable performance for groundbreaking discoveries. Contact us today to discuss how we can support your research goals!

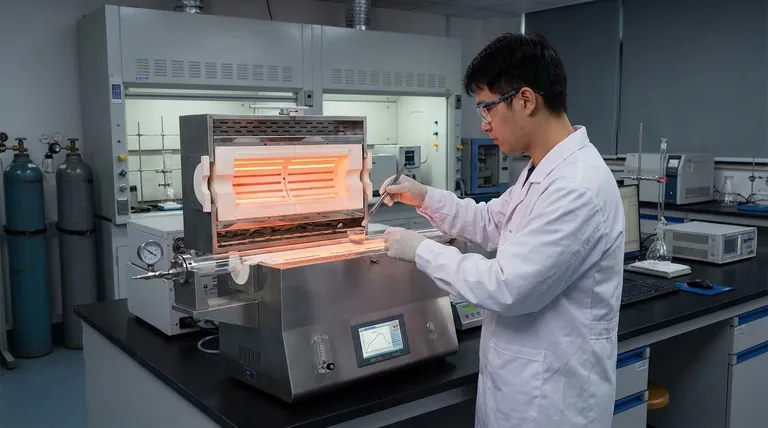

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety