A programmable tube furnace functions as a high-precision thermal reactor designed to automate the complex remelting and isothermal treatment cycles of cast iron alloys. It executes specific heating, holding, and cooling profiles to stabilize samples within the solid-liquid two-phase region while preventing oxidation through a controlled inert atmosphere.

The core value of this equipment lies in its ability to maintain thermodynamic equilibrium, allowing for the controlled coarsening of austenite dendrites which is essential for accurate solute partitioning studies.

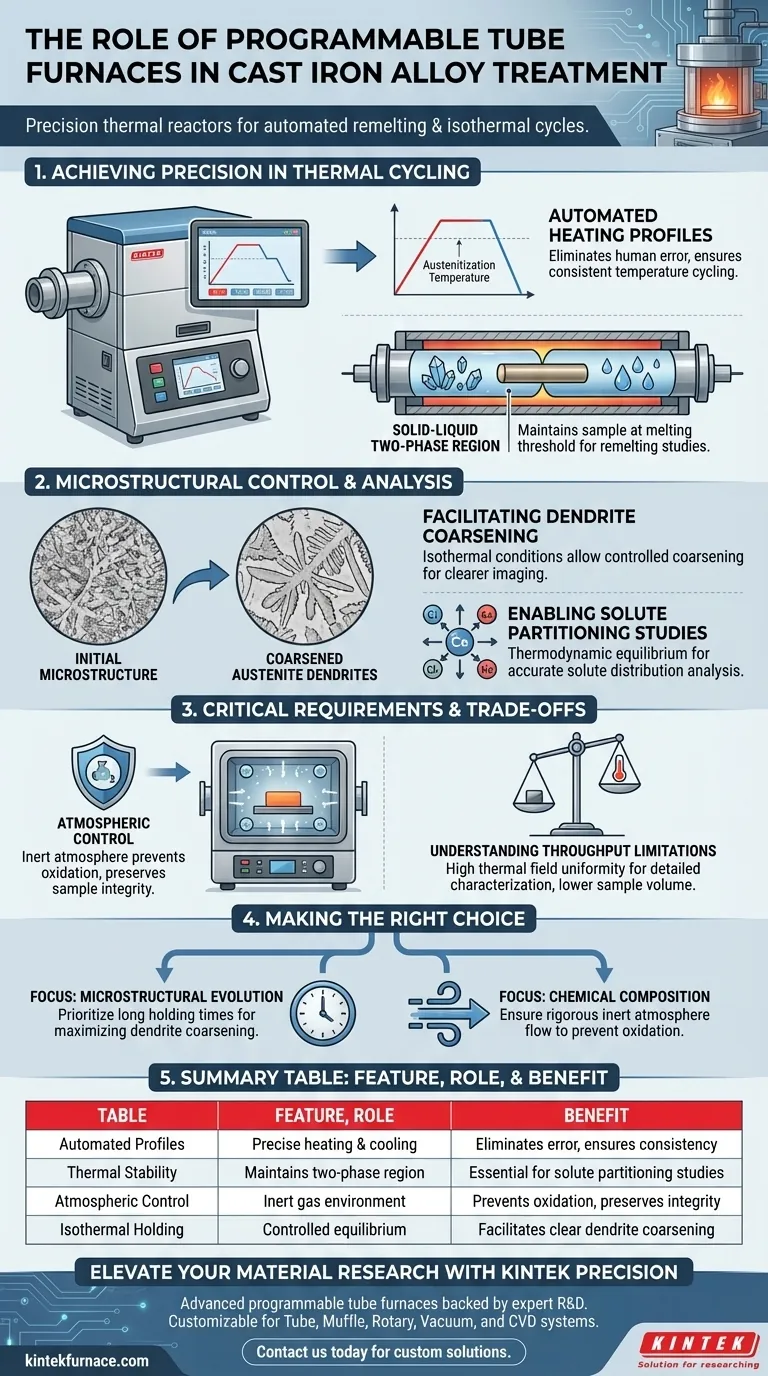

Achieving Precision in Thermal Cycling

Automated Heating Profiles

The primary function of the furnace is to remove human error from the thermal cycle.

By configuring exact heating and cooling curves, the system ensures the alloy reaches a predetermined austenitization temperature consistently every time.

Stabilizing the Two-Phase Region

For remelting studies, the alloy must be held in a state that is neither fully solid nor fully liquid.

The tube furnace maintains the sample precisely within the solid-liquid two-phase region. This stability is critical for studying how the material behaves at the threshold of melting.

Microstructural Control and Analysis

Facilitating Dendrite Coarsening

Once the thermal equilibrium is established, the microstructure begins to evolve.

The specific isothermal conditions allow austenite dendrites to coarsen over time. This controlled growth provides a larger, more distinct structure for analysis.

Enabling Solute Partitioning Studies

The ultimate goal of this thermal manipulation is often chemical characterization.

By establishing equilibrium, the furnace enables researchers to observe how different elements (solutes) distribute themselves between the solid and liquid phases.

Critical Requirements and Trade-offs

The Necessity of Atmospheric Control

Temperature control alone is insufficient for cast iron alloys.

The furnace must provide an inert atmosphere to prevent the sample from oxidizing during the high-temperature hold. Without this protective environment, surface degradation would compromise the solute analysis.

Understanding Throughput Limitations

While programmable tube furnaces offer high precision, they generally process small sample volumes.

This limitation is a trade-off for the exceptional uniformity of the thermal field. It is an instrument designed for detailed characterization rather than bulk processing.

Making the Right Choice for Your Goal

To maximize the utility of a programmable tube furnace for cast iron analysis, align your settings with your specific research objectives:

- If your primary focus is Microstructural Evolution: Prioritize long holding times within the two-phase region to maximize the coarsening of austenite dendrites for clearer imaging.

- If your primary focus is Chemical Composition: Ensure the inert atmosphere flow is rigorously maintained to prevent oxidation from skewing solute partitioning data.

Precision in the furnace settings directly correlates to the reliability of your thermodynamic data.

Summary Table:

| Feature | Role in Cast Iron Treatment | Benefit to Researcher |

|---|---|---|

| Automated Profiles | Precise heating & cooling curves | Eliminates human error & ensures consistency |

| Thermal Stability | Maintains solid-liquid two-phase region | Essential for accurate solute partitioning studies |

| Atmospheric Control | Inert gas environment | Prevents oxidation and preserves sample integrity |

| Isothermal Holding | Controlled thermodynamic equilibrium | Facilitates clear austenite dendrite coarsening |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your alloy studies with KINTEK’s advanced programmable tube furnaces. Backed by expert R&D and world-class manufacturing, we provide high-precision thermal systems—including Tube, Muffle, Rotary, Vacuum, and CVD systems—specifically engineered to meet the rigorous demands of cast iron remelting and isothermal treatment.

Whether you need custom dimensions or specific atmospheric controls, our systems are fully customizable to suit your unique laboratory needs.

Ready to achieve superior microstructural control? Contact us today to consult with our specialists and find the perfect furnace solution for your research.

Visual Guide

References

- Ricardo Queirós, Attila Diószegi. Assessing Pore Formation due to Nitrogen Partitioning in a Hypoeutectic Cast Iron. DOI: 10.1007/s40962-024-01521-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the technical considerations for using quartz tubes for sulfidation? Optimize Your Material Purity & Stability

- Why is a high-temperature tube furnace used for SNCB preparation? Optimize Nitrogen-Doped Porous Carbon Synthesis

- What role does a tube furnace play in the physical synthesis of metal nanoparticles? Master Phase Transformation

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What role does a Vacuum Tube Furnace play in NPCu annealing? Achieve Precise Structural Homogenization

- What role does a laboratory tube furnace system play in the catalytic pyrolysis of LLDPE? Enhancing Yield and Precision

- What are tube furnaces made of? Choose the Right Material for Your Thermal Process

- Why is a long-term annealing process in a tube furnace essential for Bi-Sb alloy? Achieve Material Homogeneity