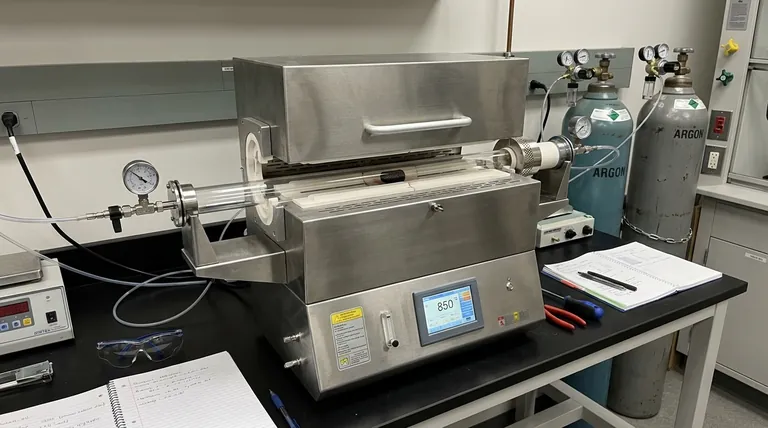

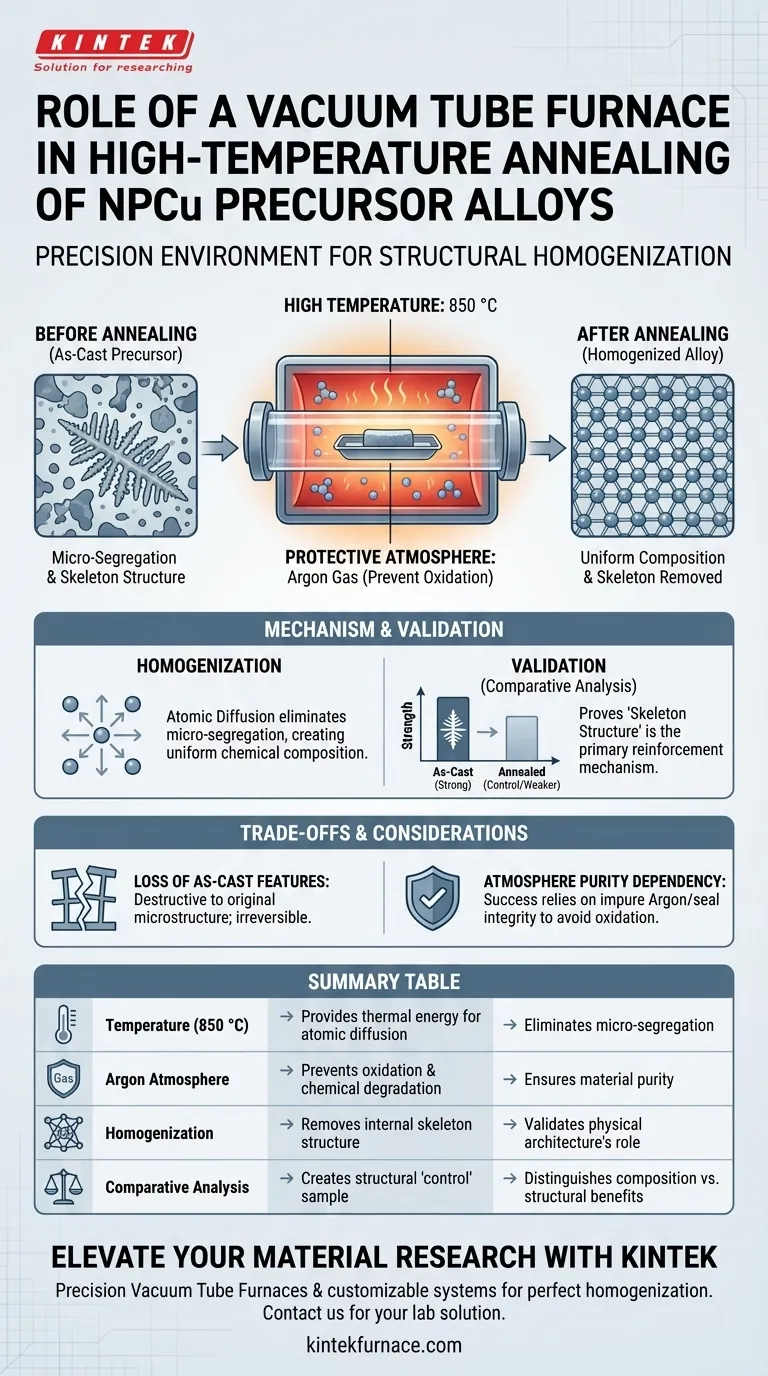

A Vacuum Tube Furnace acts as a precision environment for structural homogenization. In the processing of nanoporous copper (NPCu) precursor alloys, its primary role is to subject the material to high temperatures—specifically around 850 °C—under a protective argon atmosphere. This treatment is critical for eliminating micro-segregation that naturally occurs during the initial casting of the alloy.

By removing the solidification-induced skeleton structure through annealing, the furnace allows researchers to isolate variables. It proves that the skeleton structure, rather than just the alloy's chemical composition, is the primary mechanism responsible for the material's mechanical strength.

The Mechanism of Homogenization

Establishing the Protective Environment

To alter the internal structure of the alloy without degrading it, the Vacuum Tube Furnace creates a highly controlled setting.

The process utilizes a protective argon atmosphere to surround the sample. This inert gas prevents oxidation and other unwanted chemical reactions that would otherwise occur at high temperatures.

Eliminating Micro-Segregation

When alloys initially solidify, they often suffer from micro-segregation, where elements are unevenly distributed.

The furnace heats the precursor alloy to 850 °C, providing the thermal energy required for atoms to diffuse. This results in a uniform, homogenized material where the chemical composition is consistent throughout.

Validating Reinforcement Mechanisms

Removing the Skeleton Structure

A key objective of using the Vacuum Tube Furnace in this context is to alter the physical architecture of the alloy.

The high-temperature annealing process specifically targets and removes the solidification-induced skeleton structure. This structure is a natural byproduct of the casting process and is suspected to be a source of strength.

Enabling Comparative Analysis

Once the skeleton structure is removed via annealing, researchers can test the material's mechanical properties.

By comparing the annealed alloy (homogenized) against the original precursor (with the skeleton structure), scientists can definitively demonstrate the role of the structure. If the annealed version is weaker, it confirms that the skeleton structure is the primary reinforcement mechanism.

Understanding the Trade-offs

Loss of As-Cast Features

The annealing process is destructive to the original microstructure.

While this is intentional for creating a control group, it means the treated sample loses the unique characteristics derived from rapid solidification. You cannot revert the material to its "as-cast" state once annealed.

Dependency on Atmosphere Purity

The success of this process relies entirely on the integrity of the argon environment.

If the vacuum seal is compromised or the argon is impure, the high temperatures (850 °C) will lead to rapid oxidation rather than homogenization, ruining the sample and invalidating the comparison.

Applying This to Material Research

To effectively utilize a Vacuum Tube Furnace for NPCu precursor studies, align your process with your research objectives:

- If your primary focus is proving structural reinforcement: Anneal the precursor to remove the skeleton structure, creating a baseline "control" sample to compare against the strong, as-cast material.

- If your primary focus is alloy uniformity: Utilize the 850 °C argon environment to eliminate micro-segregation, ensuring consistent chemical properties across the sample.

This thermal treatment is the definitive step required to distinguish between strength derived from material composition and strength derived from physical structure.

Summary Table:

| Process Feature | Functional Role | Research Impact |

|---|---|---|

| Temperature (850 °C) | Provides thermal energy for atomic diffusion | Eliminates solidification-induced micro-segregation |

| Argon Atmosphere | Prevents oxidation and chemical degradation | Ensures material purity during high-heat cycles |

| Homogenization | Removes the internal skeleton structure | Validates the physical architecture's role in strength |

| Comparative Analysis | Creates a structural 'control' sample | Distinguishes composition benefits from structural benefits |

Elevate Your Material Research with KINTEK

Precision is the key to unlocking the secrets of alloy reinforcement. KINTEK provides state-of-the-art Vacuum Tube Furnaces and high-temperature systems designed to meet the rigorous demands of your laboratory research.

Backed by expert R&D and manufacturing, we offer fully customizable Muffle, Tube, Rotary, Vacuum, and CVD systems to ensure your annealing processes achieve perfect homogenization every time.

Ready to refine your thermal processing? Contact us today to find the ideal solution for your lab!

Visual Guide

References

- Haozhang Zhong, Ma Qian. Skeletal High‐Strength Nanoporous Copper and Metamaterials: The Hakka Tulou Design Heritage. DOI: 10.1002/adma.202503701

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the dimensions and temperature capabilities of single zone horizontal tube furnace models? Explore Key Specs for Your Lab

- What are tube furnaces made of? Choose the Right Material for Your Thermal Process

- How does heating zone length impact tube furnace performance? Optimize Uniformity and Capacity

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- Why must catalysts undergo reduction in a tube furnace? Master Your Furfural Hydrogenation Preparation

- Why are a high-temperature tube furnace and its reduction atmosphere control system core equipment for SrVO3?

- What features enable vacuum and gas handling in a tube furnace? Unlock Precise Atmospheric Control for Your Lab

- How should crucibles be selected for tube furnaces? Ensure Chemical Purity and Thermal Uniformity