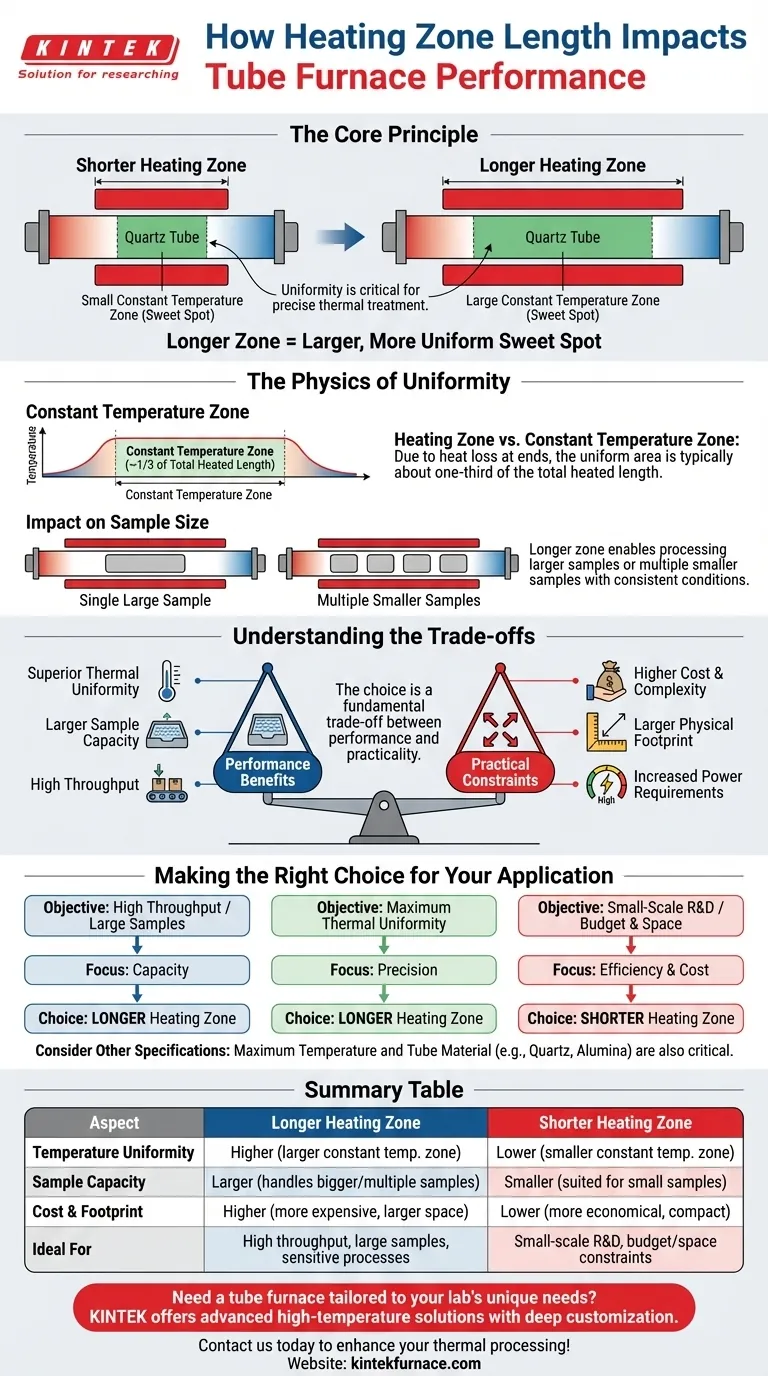

In short, a longer heating zone allows you to process larger samples and provides a more uniform temperature distribution. This is because any furnace naturally has cooler temperatures at its ends, so a longer heated length creates a larger central region with a stable, consistent temperature. This uniformity is critical for applications requiring precise and even thermal treatment across the entire sample.

The choice of heating zone length is a fundamental trade-off between performance and practicality. While longer zones deliver superior thermal uniformity and sample capacity, they come at the cost of a larger physical footprint and higher expense.

The Physics of the Constant Temperature Zone

A tube furnace's primary goal is to create an area of highly stable and uniform temperature. The heating zone length is the single most important factor in achieving this.

Defining the Heating Zone

The heating zone is the total length of the furnace tube that is actively heated by the surrounding elements. However, not all of this length will be at the target temperature.

Due to heat loss at the ends of the furnace, the temperature profile along the tube is never perfectly flat. The actual area of stable, uniform temperature—known as the constant temperature zone—is always shorter than the total heating zone.

The Quest for Uniformity

Think of the heating zone like a long fireplace. The area directly in the center is the hottest and most consistent, while the areas near the edges are cooler.

A longer heating zone creates a much larger central "sweet spot." As a general rule, the constant temperature zone is typically about one-third of the total heated length. Therefore, a longer furnace directly translates to a larger working area with reliable temperature uniformity.

Impact on Sample Size and Throughput

This directly influences what you can process. A longer constant temperature zone allows you to either accommodate a single, larger sample or process multiple smaller samples simultaneously, all while ensuring they experience the same thermal conditions. This is vital for batch processing and achieving reproducible results.

Understanding the Trade-offs

While a longer heating zone offers clear performance benefits, the decision is not always straightforward. You must weigh these advantages against practical constraints.

Performance vs. Cost and Complexity

Longer heating zones require more heating elements, more insulation, and more sophisticated control systems to maintain uniformity. This directly increases the furnace's initial purchase price and potential maintenance costs.

Footprint and Power Requirements

A larger furnace naturally occupies more valuable lab space. It will also consume more power to maintain its target temperature, which can impact operational budgets over the long term.

When Shorter Zones Are the Right Choice

A shorter heating zone is often a perfectly suitable and more economical choice for R&D on very small samples or for processes where only a small area needs to be heated. For some applications, such as crystal growth, a deliberate temperature gradient near the ends of the zone may even be desirable.

Other Critical Furnace Specifications

While heating zone length is a key factor, remember that it works in concert with other parameters. The furnace's maximum temperature and the tube material (e.g., quartz, alumina) are equally critical for matching the furnace to your specific chemical processes.

Making the Right Choice for Your Application

To select the correct heating zone length, you must first define your primary objective.

- If your primary focus is high throughput or processing large samples: A longer heating zone is necessary to provide the required capacity.

- If your primary focus is maximum thermal uniformity for sensitive processes: Choose a longer heating zone to guarantee a substantial and stable constant temperature region.

- If your primary focus is budget and space constraints with small-scale R&D: A shorter, more compact heating zone is often the most practical and cost-effective solution.

By understanding this direct relationship between length, uniformity, and capacity, you can confidently select a furnace that aligns perfectly with your scientific and operational goals.

Summary Table:

| Aspect | Longer Heating Zone | Shorter Heating Zone |

|---|---|---|

| Temperature Uniformity | Higher (larger constant temperature zone) | Lower (smaller constant temperature zone) |

| Sample Capacity | Larger (handles bigger or multiple samples) | Smaller (suited for small samples) |

| Cost & Footprint | Higher (more expensive, larger space) | Lower (more economical, compact) |

| Ideal For | High throughput, large samples, sensitive processes | Small-scale R&D, budget/space constraints |

Need a tube furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise alignment with your experimental requirements for superior performance and efficiency. Contact us today to discuss how we can enhance your thermal processing!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents