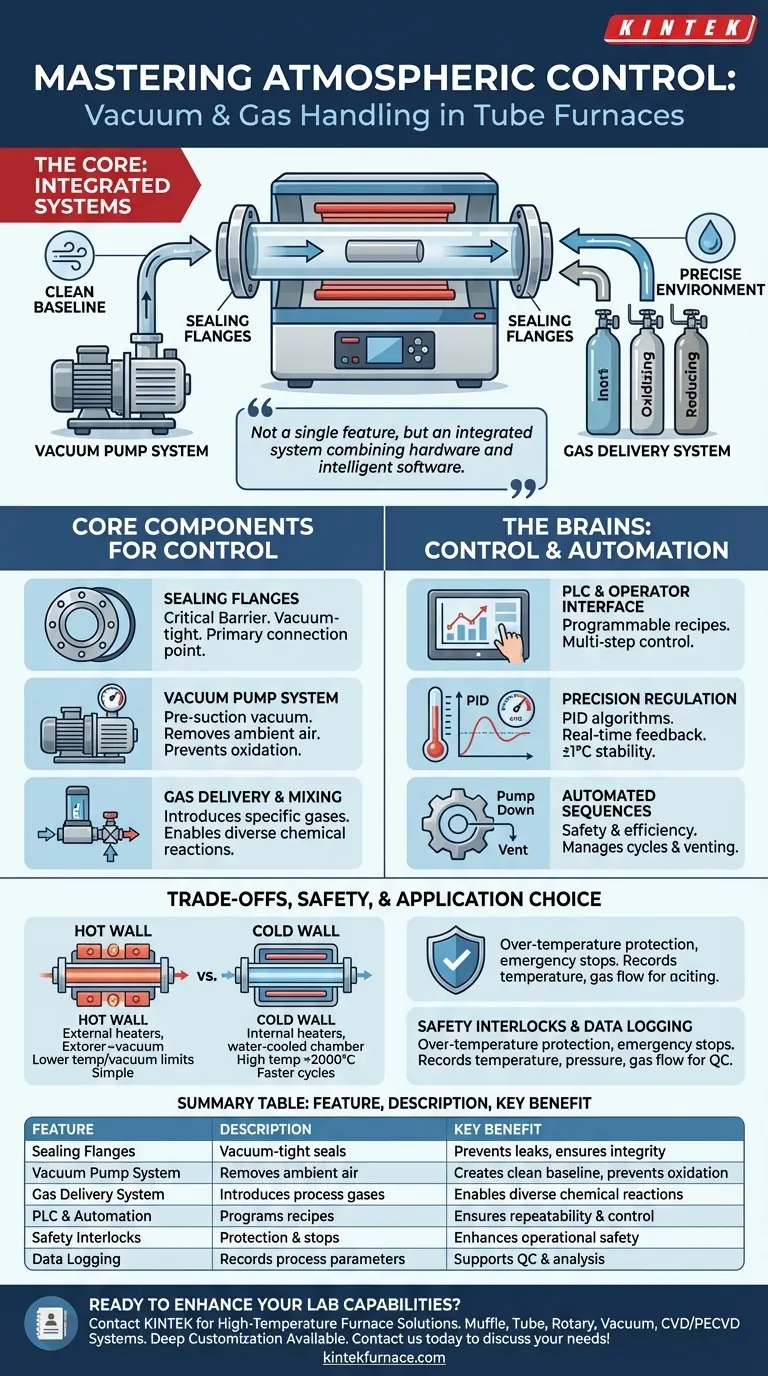

At the core of a tube furnace's atmospheric control are two integrated systems: a vacuum pump connected via specialized sealing flanges and a gas delivery system governed by advanced controllers. These features work in concert to remove ambient air and then introduce a precisely managed environment—be it a vacuum, an inert gas, or a reactive gas—which is essential for high-temperature material processing.

The ability to handle vacuum and gas is not about a single feature, but an integrated system. It combines robust hardware like sealed flanges and pumps with intelligent software that automates and controls the interplay between temperature, pressure, and gas composition for reproducible results.

The Core Components for Atmospheric Control

To achieve a controlled atmosphere, a tube furnace relies on several key pieces of hardware that must work together seamlessly. The failure of any one component compromises the integrity of the entire system.

Sealing Flanges: The Critical Interface

The sealing flanges at the ends of the process tube are the most critical physical barrier. These components must create a perfect, vacuum-tight seal to prevent any leaks from the outside environment.

They also serve as the primary connection point for both the vacuum and gas systems, acting as the gateway for controlling the internal atmosphere.

The Vacuum Pump System: Creating the Void

A vacuum pump system is connected directly to a sealing flange. Its primary function is to perform a "pre-suction vacuum," which removes ambient air and any contaminants before heating or introducing process gases.

This ensures the experiment starts from a clean, controlled baseline, which is crucial for preventing unwanted chemical reactions like oxidation. The furnace may be operated under this vacuum or use it as a precursor to introducing another gas.

Gas Delivery and Mixing: Introducing the Process Atmosphere

Once a vacuum is established, the system can introduce specific gases. The furnace can be connected to gas sources to introduce protective (e.g., Argon, Nitrogen), oxidizing (e.g., Oxygen), or reducing (e.g., Hydrogen) atmospheres.

This capability is essential for a wide range of applications, from preventing oxidation during annealing to facilitating specific chemical reactions on a material's surface.

The Brains of the Operation: Control and Automation

Hardware alone is insufficient for modern research and production. The true power of a vacuum and gas handling system lies in its sophisticated control and automation capabilities.

The PLC and Operator Interface

Modern tube furnaces are managed by a Programmable Logic Controller (PLC), typically accessed through a color touch-panel interface. This allows operators to program complex recipes with multiple steps.

Key programmable functions include temperature ramps and soaks, vacuum set points, and timed gas backfills. This level of automation ensures processes are repeatable and executed precisely every time.

Precision Temperature and Pressure Regulation

Atmosphere control is intrinsically linked to temperature control. These systems use advanced algorithms like PID regulation and self-tuning to maintain extremely stable temperatures, often with an accuracy of ±1°C.

Simultaneously, a digital vacuum display provides real-time feedback on the chamber pressure. In more advanced setups, multi-zone heating allows for different temperature profiles along the length of the tube, further enhancing process control.

Automated Sequences: Pump Downs and Vents

The PLC automates system overhead functions that are critical for safety and efficiency. This includes managing pump-down cycles to reach the target vacuum level and controlling venting procedures to safely bring the chamber back to atmospheric pressure.

Understanding the Trade-offs and Safety

While powerful, these systems come with design trade-offs and require strict adherence to safety protocols. Understanding these nuances is critical for selecting the right furnace and operating it correctly.

Hot Wall vs. Cold Wall Designs

Tube furnaces come in two main designs. Hot wall furnaces heat the entire process tube from the outside, which is simpler but can limit the ultimate temperature and vacuum level.

Cold wall furnaces use internal heating elements inside a water-cooled chamber. This design allows for higher operating temperatures (often >2000°C), faster heating/cooling cycles, and greater temperature uniformity, making it superior for many advanced vacuum applications.

Safety Interlocks and Data Logging

Given the high temperatures and controlled atmospheres, safety is paramount. Furnaces are equipped with over-temperature protection and interlocks that can trigger an emergency stop.

Furthermore, integrated data logging is a crucial feature. It records the entire process—temperature, pressure, and gas flow over time—providing a critical record for quality control and experimental analysis.

Making the Right Choice for Your Application

Selecting a furnace requires matching its capabilities to your specific experimental or production goals.

- If your primary focus is material purity and degassing: Prioritize a system with high-quality sealing flanges and a powerful vacuum pump to achieve the lowest possible base pressure.

- If your primary focus is complex, multi-stage processing: Choose a furnace with an advanced PLC that allows for easy programming of temperature ramps, soaks, and automated gas backfills.

- If your primary focus is high-temperature synthesis (>1200°C) under vacuum: A cold-wall furnace design is the superior choice for achieving higher temperatures, faster cycle times, and better uniformity.

Ultimately, understanding how these hardware and software features integrate empowers you to execute highly controlled and repeatable thermal processes.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Sealing Flanges | Vacuum-tight seals at tube ends | Prevents leaks, ensures atmospheric integrity |

| Vacuum Pump System | Removes ambient air and contaminants | Creates clean baseline, prevents oxidation |

| Gas Delivery System | Introduces inert, oxidizing, or reducing gases | Enables diverse chemical reactions and protection |

| PLC and Automation | Programs temperature, pressure, and gas sequences | Ensures repeatability and precise control |

| Safety Interlocks | Over-temperature protection and emergency stops | Enhances operational safety |

| Data Logging | Records temperature, pressure, and gas flow over time | Supports quality control and analysis |

Ready to enhance your laboratory's capabilities with advanced tube furnaces? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need precise atmospheric control, high-temperature synthesis, or automated processing, we're here to help. Contact us today to discuss how our solutions can bring efficiency and reliability to your thermal processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing