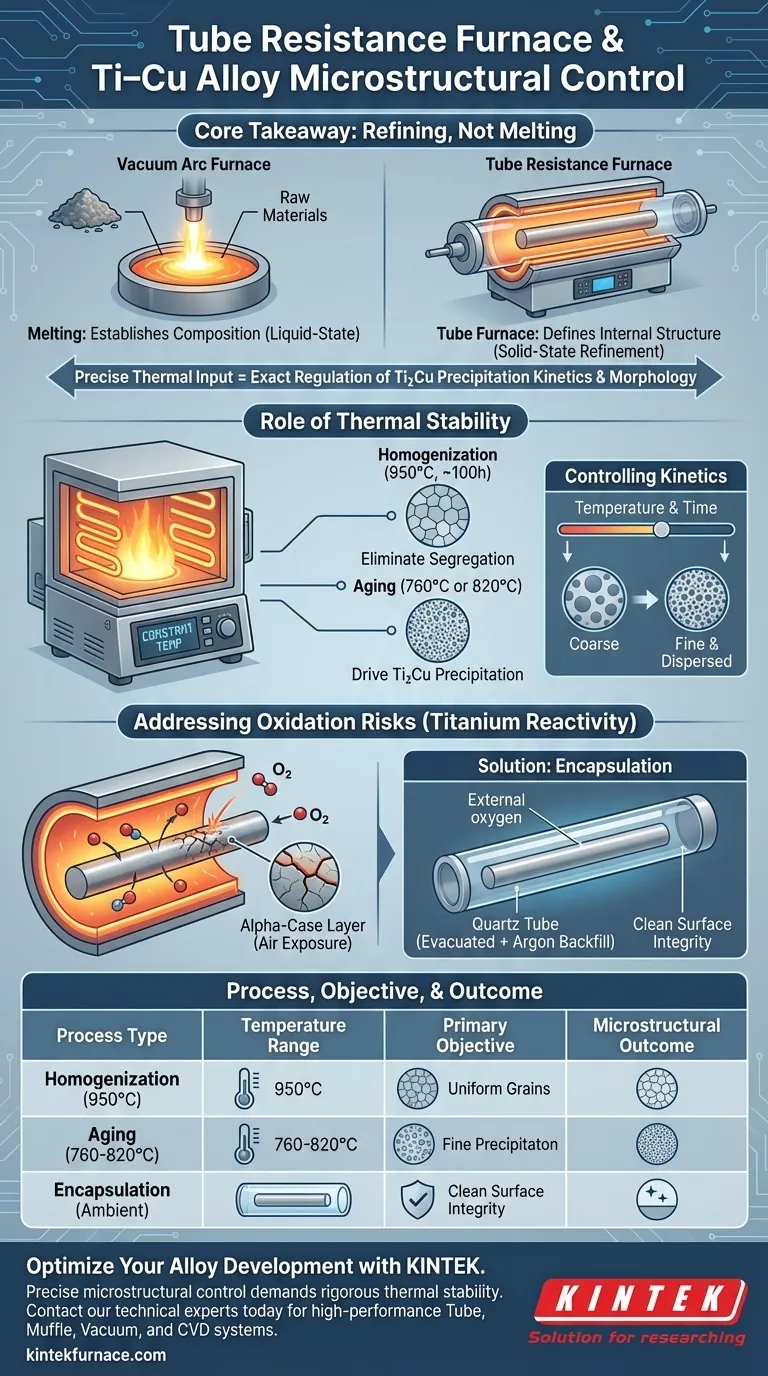

A tube resistance furnace acts as a precision instrument for regulating the solid-state phase transformations of Titanium-Copper (Ti–Cu) alloys. It provides a stable, constant-temperature environment essential for homogenization and aging treatments, allowing researchers to accurately control the precipitation kinetics of the $\text{Ti}_2\text{Cu}$ intermetallic compound.

Core Takeaway While melting establishes the alloy's composition, the tube resistance furnace defines its internal structure. Its ability to deliver precise thermal input over extended periods enables the exact regulation of particle size, morphology, and distribution, which dictates the material's final mechanical properties.

The Role of Thermal Stability

Enabling Critical Heat Treatments

The primary contribution of the tube resistance furnace is its ability to maintain a rigorously constant temperature. This stability is required for two distinct processes: homogenization at 950°C and aging treatments at either 760°C or 820°C.

Triggering Phase Transformations

Titanium-Copper alloys rely on solid-state phase transformations to achieve their desired properties. The precise thermal input from the furnace provides the energy necessary to trigger these changes, specifically the precipitation of the $\text{Ti}_2\text{Cu}$ intermetallic compound.

Controlling Precipitation Kinetics

The furnace allows for the manipulation of "kinetics"—essentially the speed and growth rate of microstructural changes. By adjusting the temperature and holding time, you can fine-tune the size and distribution of the precipitated phases, moving from a coarse structure to a fine, dispersed one as needed.

Distinguishing the Equipment's Purpose

Solid-State vs. Liquid-State Processing

It is vital to distinguish the tube resistance furnace from a vacuum arc furnace.

The vacuum arc furnace uses a high-energy arc to melt raw materials (titanium sponge and copper) into a liquid state for preliminary shaping.

Refinement vs. Creation

In contrast, the tube resistance furnace does not melt the material. It refines the solid alloy. It takes the cast material and applies controlled heat to organize the internal microstructure without changing the chemical composition or shape.

Understanding the Trade-offs: Oxidation Risks

The Reactivity Challenge

While the tube resistance furnace excels at thermal control, it poses a challenge regarding atmospheric exposure. Titanium alloys are highly reactive with oxygen and nitrogen at the temperatures required for treatment (950°C).

The Risk of Alpha-Case Layers

Exposure to air inside a standard furnace at these temperatures can lead to the formation of a hard, brittle alpha-case layer on the surface. This degrades the material's inherent properties.

The Necessity of Encapsulation

To mitigate this, the furnace is rarely used in isolation for these alloys. Samples are typically encapsulated within evacuated quartz tubes backfilled with argon.

This provides dual-atmosphere protection, ensuring the alloy remains unoxidized during long processes (up to 100 hours), allowing the furnace to do its job without compromising surface integrity.

Making the Right Choice for Your Goal

If you are designing a heat treatment protocol for Ti-Cu alloys, consider how your specific objectives dictate the furnace settings:

- If your primary focus is compositional uniformity: Use the furnace for homogenization at 950°C with extended holding times (e.g., 100 hours) to eliminate segregation from casting.

- If your primary focus is strengthening the alloy: Use the furnace for aging at 760°C or 820°C to drive the precipitation of the $\text{Ti}_2\text{Cu}$ phase.

- If your primary focus is surface integrity: Ensure your samples are encapsulated in quartz with argon before entering the furnace to prevent brittle alpha-case formation.

Success in microstructural control relies not just on the heat, but on the precise calibration of time and temperature to dictate the morphology of the $\text{Ti}_2\text{Cu}$ phase.

Summary Table:

| Process Type | Temperature Range | Primary Objective | Microstructural Outcome |

|---|---|---|---|

| Homogenization | ~950°C | Eliminate casting segregation | Uniform solid solution composition |

| Aging Treatment | 760°C - 820°C | Drive precipitation kinetics | Controlled Ti2Cu particle distribution |

| Encapsulation | Ambient to Peak | Prevent surface oxidation | Avoidance of brittle alpha-case layer |

Optimize Your Alloy Development with KINTEK

Precise microstructural control in Ti-Cu alloys demands rigorous thermal stability and specialized atmospheric management. KINTEK provides high-performance Tube, Muffle, Vacuum, and CVD systems tailored for advanced metallurgy. Backed by expert R&D and manufacturing, our customizable high-temperature furnaces empower labs to achieve exact phase transformation kinetics while maintaining material integrity.

Ready to elevate your research precision? Contact our technical experts today to find the perfect furnace solution for your unique needs.

Visual Guide

References

- Daisy Rabbitt. Antimicrobial Titanium–Copper Alloys: The Role of Microstructure in Arc‐Melted Compositions. DOI: 10.1002/adem.202500347

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What factors affect the price of a horizontal tube furnace? Key Drivers from Temperature to Control Systems

- How is a high-precision laboratory balance installed in a tube furnace? Master Thermal Isolation for Precise Data

- How does the positioning of the substrate within a tube furnace affect the in-situ growth of SnSe2 and SnSe?

- What role does an industrial-grade tube furnace play in the pyrolysis of nickel-modified molybdenum carbide catalysts?

- How do you clean an alumina tube furnace? Ensure Peak Performance & Longevity

- How does a tube muffle furnace contribute to the carbonization process of Rosa roxburghii residue biochar?

- What is a tube furnace and its main characteristics? Discover Precision Heating for Your Lab

- How do Quartz Tube Furnaces support controlled atmosphere experiments? Master Precise Material Synthesis