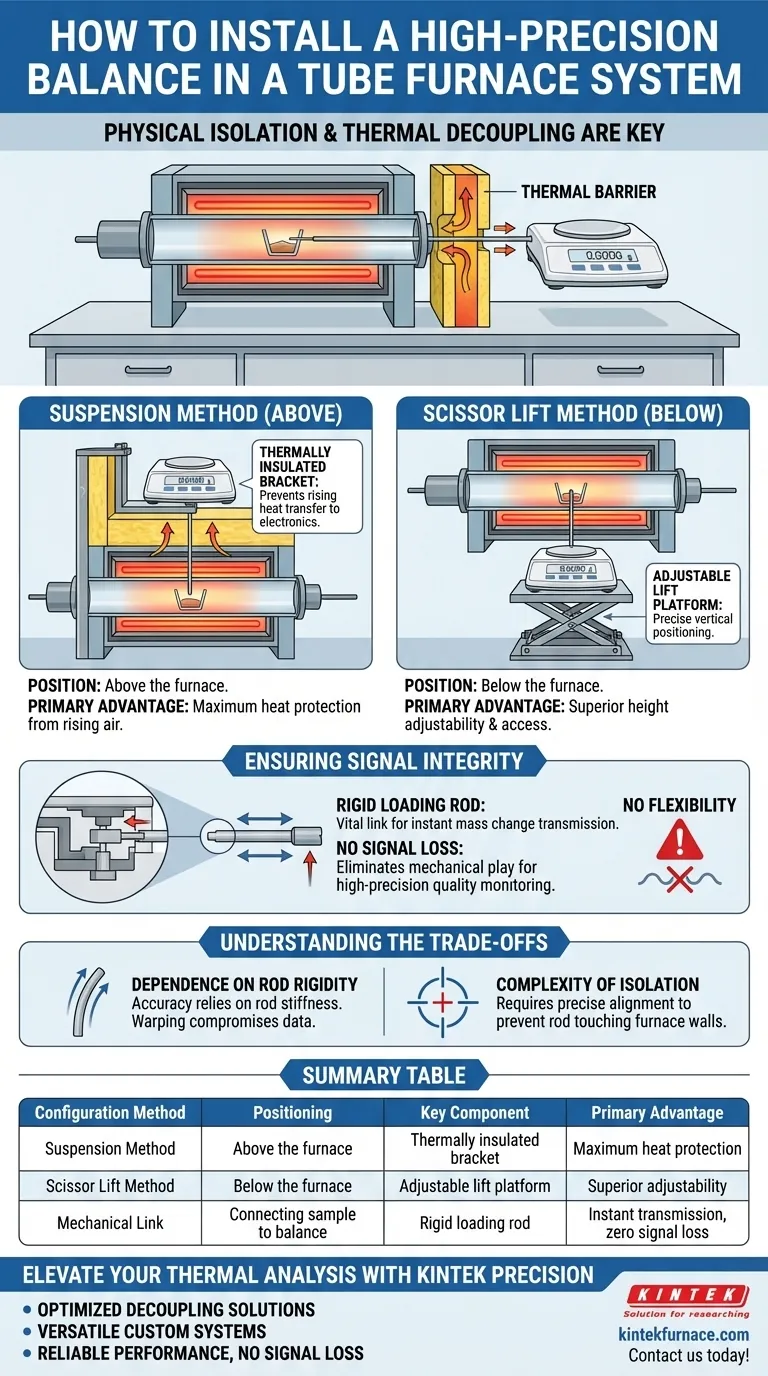

Physical isolation is the key to integration. To prevent thermal interference in a modern tube furnace system, the high-precision laboratory balance is never installed directly within the heating zone. Instead, it is either suspended above the furnace using a thermally insulated bracket or positioned below the unit on a scissor lift, connecting to the sample via a specialized rod.

To maintain high-precision monitoring in high-temperature environments, the sensitive balance electronics must be mechanically coupled but thermally decoupled from the furnace. This is achieved by locating the balance outside the heat zone and using a rigid rod to transmit mass changes instantly without signal loss.

Critical Installation Configurations

The primary goal of installation is to create a safe distance between the heat source and the measurement sensors. There are two standard configurations used to achieve this.

The Suspension Method

One common approach involves suspending the balance above the furnace. This is achieved using a specialized bracket designed to hold the balance securely in place.

Thermal Insulation

Crucially, the bracket used in the suspension method is equipped with thermal insulation. This prevents the rising heat from the furnace casing from transferring to the balance and affecting its sensitive electronics.

The Scissor Lift Method

Alternatively, the balance can be placed below the furnace. In this configuration, a scissor lift is often used to support the balance, allowing for precise vertical positioning relative to the furnace tube.

Ensuring Signal Integrity

Once the balance is physically isolated, the challenge becomes transmitting the weight data from the hot zone to the cool balance without errors.

The Rigid Loading Rod

The vital link between the sample inside the furnace and the balance outside is a rigidly connected loading rod. This rod extends from the balance mechanism into the heating zone where the sample resides.

Preventing Signal Loss

The rigidity of this connection is non-negotiable. It ensures that any change in sample mass is transmitted instantaneously and accurately to the balance sensors.

Quality Monitoring results

By eliminating mechanical "play" or flexibility in the connection, this setup guarantees no signal loss. This allows for high-precision quality monitoring even while the sample undergoes extreme thermal processing.

Understanding the Trade-offs

While isolating the balance protects it from heat, it introduces mechanical dependencies that must be managed.

Dependence on Rod Rigidity

The accuracy of the entire system relies heavily on the stiffness of the loading rod. If the rod warps or bends under thermal stress, the transmission of mass changes will be compromised, leading to inaccurate data.

Complexity of Isolation

Separating the balance requires a more complex physical footprint than a standard weighing setup. Whether using a suspension bracket or a scissor lift, the system requires precise alignment to ensure the rod moves freely without touching the furnace walls.

Optimizing Your Setup for Precision

To ensure your tube furnace yields the most accurate gravimetric data, choose the configuration that best fits your operational constraints.

- If your primary focus is thermal protection: Prioritize the suspension method with an insulated bracket, as heat naturally rises and the insulation provides a critical barrier.

- If your primary focus is adjustability: Consider the scissor lift configuration below the furnace, which allows for easier manipulation of the balance height relative to the tube.

Proper mechanical isolation ensures that your thermal processing data remains precise, regardless of the furnace temperature.

Summary Table:

| Configuration Method | Positioning | Key Component | Primary Advantage |

|---|---|---|---|

| Suspension Method | Above the furnace | Thermally insulated bracket | Maximum heat protection from rising air |

| Scissor Lift Method | Below the furnace | Adjustable lift platform | Superior height adjustability and access |

| Mechanical Link | Connecting sample to balance | Rigid loading rod | Instant mass change transmission with zero signal loss |

Elevate Your Thermal Analysis with KINTEK Precision

Don't let thermal interference compromise your critical research data. At KINTEK, we specialize in high-performance laboratory solutions backed by expert R&D and manufacturing. Whether you require standard or fully customizable Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature furnaces are engineered to integrate seamlessly with precision monitoring tools.

Why choose KINTEK?

- Expert Engineering: Optimized mechanical and thermal decoupling solutions.

- Versatile Systems: Tailored to your unique lab requirements and sample needs.

- Reliable Performance: High-stiffness components ensure no signal loss during processing.

Ready to optimize your gravimetric setup? Contact us today to discuss your specific application with our technical experts!

Visual Guide

References

- Beata Brzychczyk, L. J. Sikora. Modernization of a Tube Furnace as Part of Zero-Waste Practice. DOI: 10.3390/su17198940

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What intelligent features are available in modern vacuum tube furnaces? Boost Precision and Efficiency in Your Lab

- How does a laboratory tube furnace contribute to the sintering process of Cu-Al2O3? Enhance Composite Density & Strength

- Why Use a High-Precision Weighing System with a Tube Furnace for Magnetite Oxidation Kinetics? Achieve Real-Time Data.

- What is the function of a tube reduction furnace in PtLaOx@S-1 catalysts? Achieve Precise Chemical Restructuring

- How does a laboratory tube diffusion furnace facilitate pre-deposition? Precision Doping for Silicon Wafer Processing

- What function does a tube furnace serve in metal nitride synthesis? Achieve High-Purity Nanoparticle Growth

- How does a programmable temperature control tube furnace contribute to the formation of pore structures in biochar?

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab