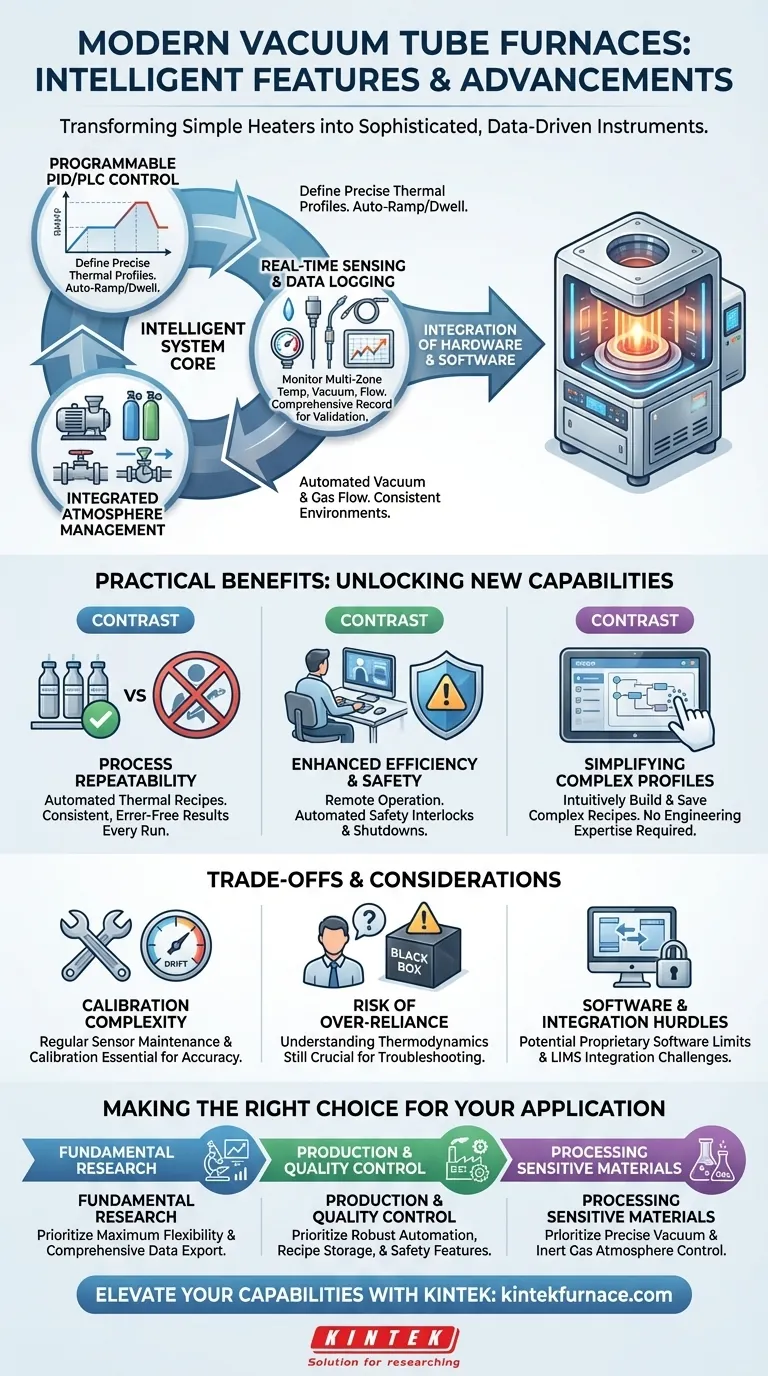

At their core, modern vacuum tube furnaces have evolved from simple heating elements into sophisticated, software-driven instruments. Their intelligent features are centered on programmable PID/PLC controllers for creating complex thermal profiles, integrated sensors for real-time process monitoring, and automation systems that enable remote operation and ensure repeatable, safe execution of tasks.

The most significant advancement is not just the addition of features, but the integration of hardware and software. This transforms the furnace from a manually operated heater into an automated system capable of precise, data-driven process control, fundamentally improving reliability and repeatability.

Beyond Heating: The Core of Furnace Intelligence

The "intelligence" of a modern vacuum furnace lies in a tightly integrated system of control logic, sensors, and user interfaces that work together to manage the entire thermal process, not just the temperature.

Programmable PID/PLC Control

The brain of the modern furnace is its programmable controller, often using a PID (Proportional-Integral-Derivative) or PLC (Programmable Logic Controller) system.

This allows you to define precise, multi-segment heating and cooling profiles. You can program specific ramp rates (e.g., heat at 10°C/minute), dwell times (e.g., hold at 800°C for 2 hours), and cooling sequences automatically.

Real-Time Sensing and Data Logging

Intelligence is impossible without data. Modern furnaces are equipped with an array of embedded sensors that monitor key parameters in real time.

These go beyond a single thermocouple, often tracking temperature in multiple zones for uniformity, as well as vacuum pressure and gas flow rates. This data is logged and can be exported, providing a complete record for process validation and quality control.

Integrated Atmosphere Management

A key intelligent function is the automated control over the furnace's internal atmosphere.

The controller doesn't just manage heat; it orchestrates the vacuum pump and gas flow systems. This ensures that a specific vacuum level is reached before heating begins or that a protective gas atmosphere is maintained consistently throughout the process.

The Practical Benefits of an Intelligent System

These integrated features deliver tangible benefits in laboratory and production environments, moving beyond convenience to unlock new capabilities.

Unlocking Process Repeatability

By automating the entire thermal recipe, from pump-down to cool-down, the furnace eliminates the variability and human error of manual operation.

Every run executes the exact same profile, ensuring that results are consistent and repeatable—a non-negotiable requirement for both scientific research and industrial quality control.

Enhancing Operational Efficiency and Safety

Remote monitoring and control allow operators to manage and check the status of a long process from their office PC, freeing them from needing to be physically present.

Crucially, intelligent systems incorporate automated safety interlocks. Features like over-temperature protection and automatic shutdown in case of a vacuum leak or other anomaly protect the equipment, the sample, and personnel.

Simplifying Complex Thermal Profiles

What would be an impossibly complex or tedious manual task becomes simple. Through modern touchscreen interfaces, operators can easily build, save, and recall intricate multi-step recipes.

This accessibility empowers users to execute sophisticated material processing protocols without needing to be an expert in control systems engineering.

Understanding the Trade-offs and Considerations

While powerful, these intelligent systems are not without their own set of challenges and require a mindful approach.

The Complexity of Calibration

An intelligent furnace is only as accurate as its sensors. Thermocouples can drift, and pressure gauges can lose accuracy over time.

Regular calibration and maintenance are critical to ensure the data driving the automated processes is correct. An uncalibrated system provides a false sense of precision.

The Risk of Over-Reliance

Automation can sometimes distance the operator from the fundamental process. It's easy to treat the furnace as a "black box," but a true understanding of the underlying thermodynamics is still essential for troubleshooting.

When a process fails, operators must be able to diagnose whether the issue lies with the material, the recipe logic, or the furnace hardware itself.

Software and Integration Hurdles

While PC integration is a key feature, it is not always a seamless, plug-and-play experience.

Proprietary software can sometimes limit data export options or create challenges when integrating the furnace into a centralized lab information management system (LIMS).

Making the Right Choice for Your Application

The specific features you prioritize should align directly with your primary goal.

- If your primary focus is fundamental research: You need maximum flexibility with multi-segment programming and comprehensive, easily exportable data logging to validate experimental conditions.

- If your primary focus is production or quality control: You need robust automation, the ability to store and lock proven recipes, and integrated safety features to ensure consistent output and operator safety.

- If your primary focus is processing sensitive materials: You need precise, integrated, and automated control over the vacuum level and inert gas atmosphere in addition to the temperature profile.

Ultimately, the intelligence in a modern furnace empowers you to move from simply heating a sample to precisely engineering a complete thermal process.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Programmable PID/PLC Control | Enables multi-segment heating/cooling profiles with precise ramp rates and dwell times. | Ensures accurate and repeatable thermal processes. |

| Real-Time Sensing and Data Logging | Uses embedded sensors for temperature, vacuum pressure, and gas flow monitoring with data export. | Provides validation and quality control through detailed process records. |

| Integrated Atmosphere Management | Automates control of vacuum pumps and gas flow systems for consistent internal environments. | Protects sensitive materials and maintains process integrity. |

| Remote Monitoring and Control | Allows operation and status checks from remote devices via user-friendly interfaces. | Increases efficiency and safety by reducing physical presence needs. |

| Automated Safety Interlocks | Includes over-temperature protection and shutdown features for anomalies like vacuum leaks. | Safeguards equipment, samples, and personnel from hazards. |

Ready to elevate your laboratory's capabilities with intelligent vacuum tube furnaces? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored for diverse labs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Unlock precise, repeatable, and safe thermal processes—contact us today to discuss how we can support your research or production goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision