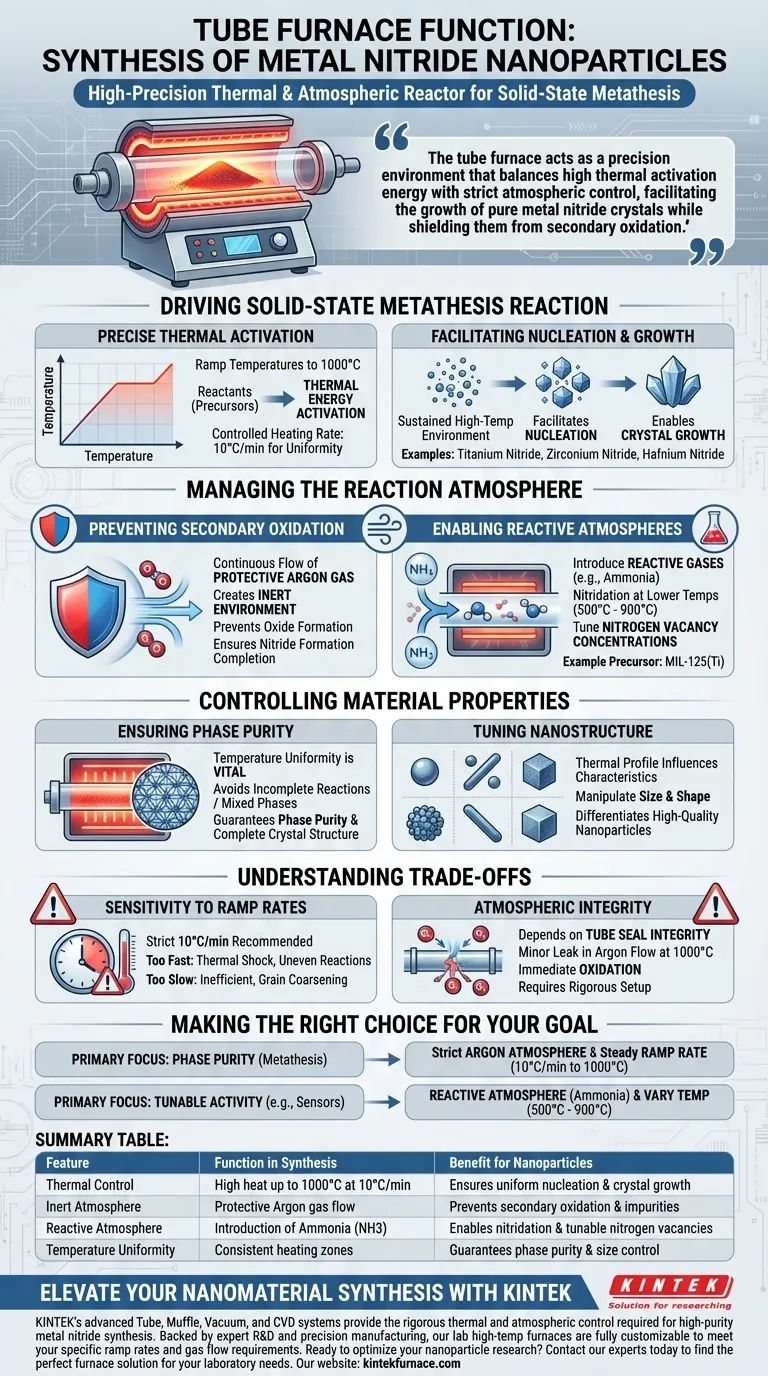

The primary function of a tube furnace in the synthesis of metal nitride nanoparticles is to provide a highly controlled thermal reactor for solid-state metathesis. By heating reactants to 1000°C at a precise rate of 10°C per minute under a flow of protective argon gas, the furnace ensures the complete nucleation and growth of crystals while strictly preventing oxidation.

The tube furnace acts as a precision environment that balances high thermal activation energy with strict atmospheric control, facilitating the growth of pure metal nitride crystals while shielding them from secondary oxidation.

Driving the Solid-State Metathesis Reaction

Precise Thermal Activation

For solid-state metathesis to occur, reactants require significant thermal energy to overcome activation barriers. A tube furnace provides this by ramping temperatures to 1000°C.

This high heat is not applied abruptly. The furnace utilizes a controlled heating rate, typically 10°C per minute, to ensure the reaction proceeds uniformly throughout the sample volume.

Facilitating Nucleation and Growth

The sustained high-temperature environment facilitates the nucleation of the metal nitride phase.

As the reaction progresses, the furnace maintains the necessary thermal conditions for these nuclei to grow into distinct crystals. This process is essential for synthesizing specific compounds such as titanium nitride, zirconium nitride, and hafnium nitride.

Managing the Reaction Atmosphere

Preventing Secondary Oxidation

One of the most critical roles of the tube furnace is the isolation of the reaction from ambient oxygen. Metal nitrides are susceptible to secondary oxidation at elevated temperatures, which would degrade the material into an unwanted oxide.

To prevent this, the furnace operates under a continuous flow of protective argon gas. This creates an inert environment that allows the nitride formation to reach completion without chemical interference.

Enabling Reactive Atmospheres

While the primary reference highlights inert argon for metathesis, the tube furnace offers versatility for other synthesis routes.

For example, when converting precursors like MIL-125(Ti), the furnace can introduce reactive gases like ammonia. This allows for nitridation at lower temperatures (500°C to 900°C) and enables researchers to tune nitrogen vacancy concentrations.

Controlling Material Properties

Ensuring Phase Purity

The temperature uniformity within the tube furnace is vital for the quality of the final nanoparticles.

Uneven heating can lead to incomplete reactions or mixed phases. By maintaining a consistent thermal zone, the furnace ensures the phase purity and complete crystal structure of the synthesized product.

Tuning Nanostructure

The specific thermal profile—including the ramp rate and maximum temperature—directly influences the physical characteristics of the nanoparticles.

By manipulating these parameters, researchers can control the size and shape of the resulting particles. This precise regulation is what differentiates high-quality engineered nanoparticles from inconsistent bulk materials.

Understanding the Trade-offs

Sensitivity to Ramp Rates

While high temperatures are necessary, the rate of heating is a critical variable. Deviating from the recommended 10°C per minute can lead to issues.

Too fast, and you risk thermal shock or uneven reaction fronts; too slow, and the process becomes inefficient or allows unwanted grain coarsening.

Atmospheric Integrity

The success of the synthesis is entirely dependent on the integrity of the tube's seal.

Even a minor leak in the argon flow system at 1000°C will result in immediate oxidation. The equipment demands rigorous setup to ensure the "protective" aspect of the atmosphere is not compromised.

Making the Right Choice for Your Goal

To maximize the effectiveness of a tube furnace for your specific synthesis, consider your primary objective:

- If your primary focus is Phase Purity (Metathesis): Prioritize a strict argon atmosphere and a steady ramp rate (10°C/min) to 1000°C to ensure complete conversion without oxidation.

- If your primary focus is Tunable Activity (e.g., Sensors): Utilize a reactive atmosphere (Ammonia) and vary the temperature between 500°C and 900°C to manipulate nitrogen vacancies.

Success in metal nitride synthesis relies not just on reaching the target temperature, but on the precise control of the atmospheric and thermal gradient throughout the entire cycle.

Summary Table:

| Feature | Function in Synthesis | Benefit for Nanoparticles |

|---|---|---|

| Thermal Control | High heat up to 1000°C at 10°C/min | Ensures uniform nucleation & crystal growth |

| Inert Atmosphere | Protective Argon gas flow | Prevents secondary oxidation & impurities |

| Reactive Atmosphere | Introduction of Ammonia (NH3) | Enables nitridation & tunable nitrogen vacancies |

| Temperature Uniformity | Consistent heating zones | Guarantees phase purity & size control |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is the difference between a successful reaction and a failed batch. KINTEK’s advanced Tube, Muffle, Vacuum, and CVD systems provide the rigorous thermal and atmospheric control required for high-purity metal nitride synthesis. Backed by expert R&D and precision manufacturing, our lab high-temp furnaces are fully customizable to meet your specific ramp rates and gas flow requirements.

Ready to optimize your nanoparticle research? Contact our experts today to find the perfect furnace solution for your laboratory needs.

Visual Guide

References

- Dreenan Shea, Mita Dasog. Decoding Plasmonic Enhancement Pathways in Group 4 Metal Nitride‐TiO<sub>2</sub> Composites: Rhodamine B Dye Degradation Case Study. DOI: 10.1002/nano.70059

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the applications of a laboratory tube furnace in chemical research? Unlock Precise High-Temperature Synthesis

- What kind of reaction environment does a laboratory tube furnace provide? Optimize Na4Fe3(PO4)2(P2O7) Synthesis

- What is the design advantage of a split tube furnace? Unlock Easy Access for Complex Lab Setups

- What is the specific role of a tube furnace in the pre-treatment of activated carbon catalysts? Precision Modification

- Why is a tube furnace with precise temperature control required for CuSbSe2 thin films? Achieve High Phase Purity

- What role does a tube furnace play in tantalum capacitor recycling? Enhancing Metal Recovery Through Pyrolysis

- How does a vertical tube gas mixing furnace function in controlling oxygen fugacity? Achieve Precise Magma Simulations

- What advanced materials research applications involve tube furnaces? Unlock Precision for Next-Gen Materials