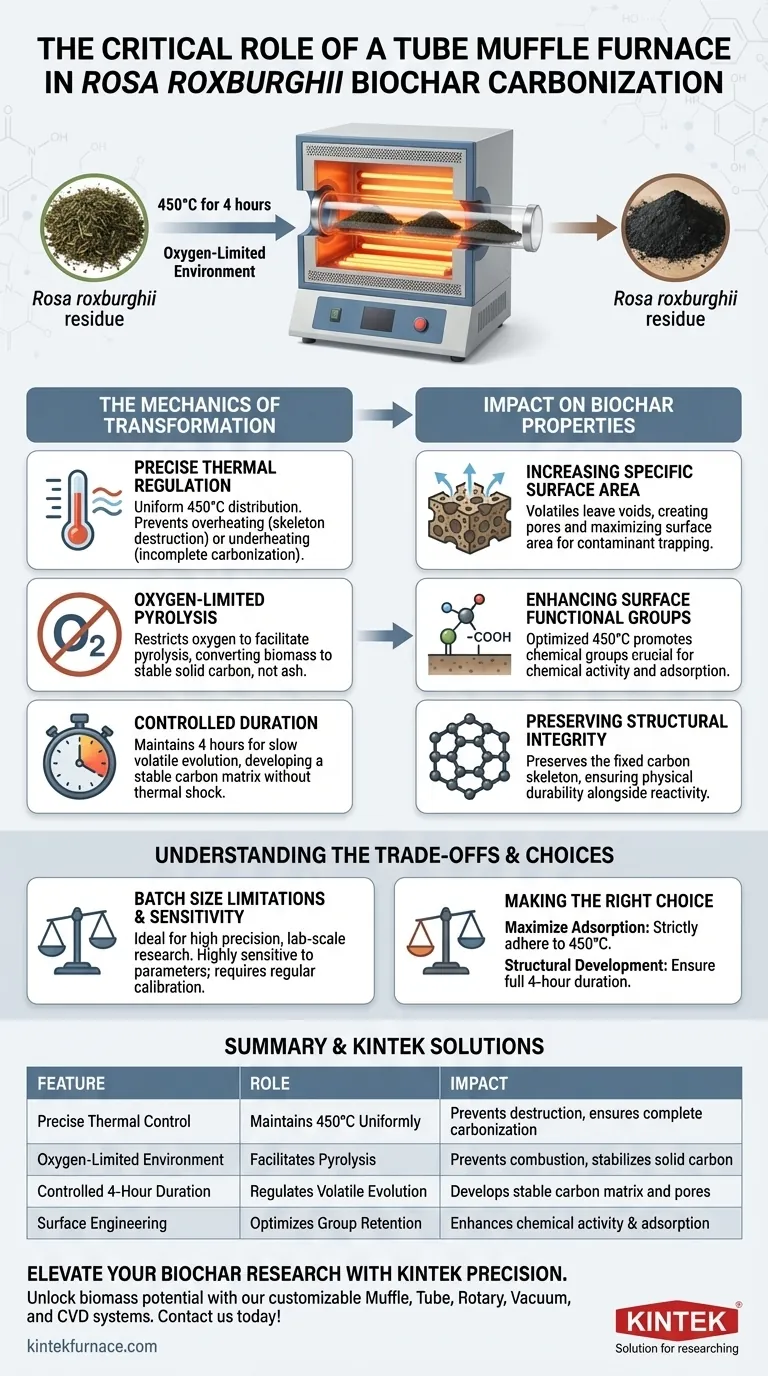

A tube muffle furnace serves as the critical precision instrument for transforming raw Rosa roxburghii residue into high-performance biochar. Specifically, it provides a strictly controlled environment at 450°C for 4 hours, enabling pyrolysis to occur under oxygen-limited conditions.

By stabilizing the thermal environment, the furnace drives the removal of volatiles while preserving the biomass's structural integrity. This balance is essential for maximizing specific surface area and generating the surface functional groups that determine the biochar's adsorption capabilities.

The Mechanics of Transformation

Precise Thermal Regulation

The core contribution of the tube muffle furnace is its ability to maintain a static temperature of 450°C.

Unlike standard ovens, a tube furnace ensures a uniform temperature distribution across the sample.

This consistency prevents localized overheating, which could destroy the desired carbon skeleton, or underheating, which would leave the carbonization incomplete.

Oxygen-Limited Pyrolysis

The furnace design allows for operation in an oxygen-limited environment.

This is the fundamental requirement for pyrolysis; if oxygen were freely available at these temperatures, the biomass would simply combust into ash.

By restricting oxygen, the furnace forces the Rosa roxburghii residue to undergo thermal decomposition rather than burning, converting organic matter into a stable solid carbon form.

Controlled Duration

The specific protocol requires a holding time of 4 hours.

The furnace maintains this duration with precision, allowing sufficient time for the slow evolution of volatiles.

This gradual process is necessary to develop a stable carbon matrix without causing the structural collapse often associated with rapid thermal shocks.

Impact on Biochar Properties

Increasing Specific Surface Area

The thermal treatment facilitates the removal of volatile components from the plant residue.

As these volatiles escape the biomass matrix, they leave behind voids, effectively creating a preliminary porous structure.

This process significantly increases the specific surface area of the material, which is a primary factor in the biochar's ability to trap contaminants.

Enhancing Surface Functional Groups

The specific temperature of 450°C is optimized to promote the formation of surface functional groups.

These chemical groups are critical for the biochar's "chemical activity."

They dictate how well the biochar can interact with and bind to specific molecules, directly influencing its adsorption activity.

Preserving Structural Integrity

While heat is necessary to remove volatiles, excessive heat or uncontrolled fluctuations can destroy the biomass's physical framework.

The tube muffle furnace preserves the integrity of the biomass structure during carbonization.

This results in a biochar that retains a fixed carbon skeleton, providing physical durability alongside chemical reactivity.

Understanding the Trade-offs

Batch Size Limitations

Tube muffle furnaces are typically designed for high precision rather than high volume.

They are ideal for laboratory-scale research or small-batch production where quality control is paramount.

However, they may not be suitable for large-scale industrial production without significant modification or parallel processing.

Sensitivity to Parameters

The quality of Rosa roxburghii biochar is highly sensitive to the specific parameters set on the furnace.

Deviating from the 450°C target or the 4-hour duration can alter the balance between pore development and functional group retention.

Users must ensure their equipment is calibrated regularly to maintain the "oxygen-limited" conditions, as leaks can ruin the sample.

Making the Right Choice for Your Goal

To maximize the utility of Rosa roxburghii residue biochar, consider your specific end-goal when configuring your thermal treatment:

- If your primary focus is maximum adsorption capacity: Strictly adhere to the 450°C limit to preserve surface functional groups, as higher temperatures may destroy them.

- If your primary focus is structural development: Ensure the 4-hour duration is met to allow complete devolatilization and the formation of a stable carbon skeleton.

Precise thermal control is not just a procedural step; it is the defining factor that turns agricultural waste into a functional chemical resource.

Summary Table:

| Feature | Role in Carbonization | Impact on Biochar |

|---|---|---|

| Precise Thermal Control | Maintains 450°C uniformly | Prevents skeleton destruction; ensures complete carbonization |

| Oxygen-Limited Environment | Facilitates true pyrolysis | Prevents combustion/ash formation; stabilizes solid carbon |

| Controlled 4-Hour Duration | Regulates slow evolution of volatiles | Develops stable carbon matrix and preliminary porous structure |

| Surface Engineering | Optimizes functional group retention | Enhances chemical activity and pollutant adsorption capacity |

Elevate Your Biochar Research with KINTEK Precision

Unlock the full potential of biomass transformation with KINTEK’s high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of your lab.

Whether you are optimizing Rosa roxburghii residue or developing next-generation adsorbents, our furnaces provide the temperature uniformity and oxygen-limited control essential for superior specific surface area and structural integrity.

Ready to achieve laboratory-grade excellence? Contact us today to find the perfect furnace for your unique needs!

Visual Guide

References

- Yong Dai, Ruyi Zheng. Adsorption and removal of pentavalent antimony from water by biochar prepared from modified rosa roxburghii residue. DOI: 10.3389/fenvs.2024.1540638

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a laboratory high-temperature tube furnace? Driving Topotactic Reduction of Nickelate Films

- How does a tube furnace facilitate the activation of xylan-derived carbon spheres? Precision Surface Engineering

- What is the specific purpose of using a laboratory tube furnace with a wet argon environment? Optimize Siloxane Curing

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- What is a tube furnace and where is it commonly used? Discover Precision Heating for Advanced Materials

- How do tube furnaces work? Achieve Precise Thermal Processing for Your Materials

- How does the temperature curve control in a quartz tube sintering furnace affect Ag-P electrode in-situ doping?

- How do sealed flanges improve oxygen annealing for superconducting joints? Enhance Purity and Precision