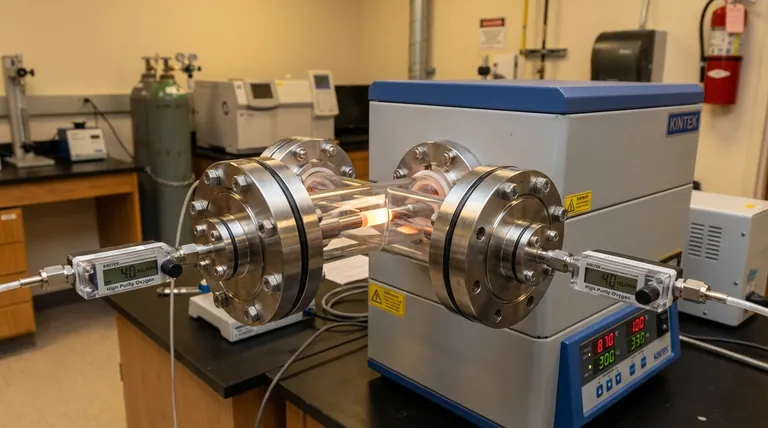

Sealed flanges act as critical isolation barriers that allow a tube furnace to maintain a 100 percent high-purity oxygen atmosphere while utilizing extremely low gas flow rates. By closing the system, these flanges eliminate the need for high-velocity gas purging, directly influencing both the thermal stability of the furnace and the chemical integrity of the annealing process.

By enabling a sealed environment, flanges reduce the required oxygen flow rate to as low as 40 mL/min, minimizing convective cooling and oxygen waste. This creates a stable thermal profile and a pure chemical environment, ensuring the complete and uniform oxygenation required for high-performance superconducting joints.

Optimizing the Thermal and Chemical Environment

Achieving Atmosphere Purity with Minimal Flow

In an open or semi-open furnace design, maintaining a pure atmosphere requires a high volume of gas to constantly flush out ambient air. Sealed flanges eliminate this requirement by creating a closed system.

This allows operators to maintain a 100 percent high-purity oxygen atmosphere with a significantly reduced flow rate. In practical applications, the flow rate can be lowered to levels as precise as 40 mL/min while still preventing external contamination.

Stabilizing Temperature Distribution

High gas flow rates introduce a secondary problem: additional convective heat transfer. When a large volume of gas moves through the tube, it actively strips heat away from the heating zone, creating temperature gradients.

By enabling a low-flow environment, sealed flanges minimize this convective cooling effect. This ensures a stable temperature distribution throughout the furnace, which is critical for uniform material processing.

Ensuring Thorough Chemical Reactions

The quality of a superconducting joint relies heavily on the thoroughness of the oxygen annealing reaction. Variations in temperature or oxygen concentration can lead to incomplete processing.

The combination of a consistent high-purity atmosphere and a thermally stable environment ensures the thoroughness of the annealing reaction. This results in superior superconducting properties compared to joints processed in fluctuating conditions.

Understanding the Operational Trade-offs

The Cost of Open Systems

While open systems may appear simpler to operate initially, they are inefficient regarding resource consumption. Without sealed flanges, the system consumes significantly higher quantities of high-purity oxygen to combat atmospheric diffusion.

Managing Convective Instability

If you choose a semi-open design, you must accept the risk of thermal instability. The high flow rates required to maintain purity will inevitably cause temperature fluctuations due to convection.

This instability makes it difficult to replicate precise annealing curves, potentially compromising the reliability of the final superconducting joint.

Making the Right Choice for Your Goal

To maximize the performance of your superconducting joints, you must match your furnace configuration to your process requirements.

- If your primary focus is process consistency: Use sealed flanges to minimize convective heat transfer and maintain a strictly uniform temperature profile.

- If your primary focus is operational efficiency: Implement a sealed design to drastically reduce the consumption of expensive high-purity oxygen by enabling low-flow operation.

Sealed flanges transform a standard tube furnace into a precision reactor capable of delivering the exact thermal and chemical conditions required for high-quality superconductivity.

Summary Table:

| Feature | Open/Semi-Open System | Sealed Flange System |

|---|---|---|

| Atmosphere Purity | Requires high flow to flush air | 100% High-purity O2 (isolated) |

| Oxygen Flow Rate | High (Inefficient) | Low (as low as 40 mL/min) |

| Thermal Stability | Convective cooling gradients | Stable, uniform temperature |

| Process Quality | Risk of incomplete reaction | Thorough, consistent annealing |

| Operational Cost | High gas consumption | Economical gas usage |

Elevate Your Superconducting Research with KINTEK Precision

Precise control over your thermal and chemical environment is the difference between a failed experiment and a high-performance superconducting joint. KINTEK provides industry-leading Tube, Muffle, Rotary, Vacuum, and CVD systems, all backed by expert R&D and manufacturing. Our systems are fully customizable to meet your specific oxygen annealing requirements, ensuring uniform heat distribution and high-purity atmosphere management.

Ready to optimize your lab's high-temperature processes? Contact KINTEK today to discuss our customizable furnace solutions and discover how we can enhance your material processing quality.

Visual Guide

References

- Zili Zhang, Qiuliang Wang. A Tube Furnace Design for the Oxygen Annealing of a REBCO Superconducting Joint. DOI: 10.3390/ma18133053

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is an alumina tube furnace? Essential for High-Temp, Contamination-Free Material Processing

- What is the core role of a tube furnace in synthesizing magnetic carbon-based composites? Expert Insights

- What role does a Horizontal Tube Furnace play in MoP single crystal preparation? Master Thermal Kinetic Control

- What are the advantages of a tube furnace? Achieve Precise, Controlled Thermal Processing

- What are the maintenance requirements for a horizontal electric furnace? Ensure Peak Performance and Longevity

- How does a vacuum tube furnace contribute to product sintering? Achieve Pure, High-Density Materials

- What are the maximum temperature capabilities for each zone in a three-zone split tube furnace? Explore Key Ranges and Control

- How does a laboratory high-temperature tube resistance furnace contribute to the aging treatment of Ni-W-Co-Ta alloys?