In essence, a vacuum tube furnace contributes to product sintering by creating a chemically pure, oxygen-free environment. This allows for the precise application of heat to bond material particles together without the risk of oxidation or other unwanted reactions that would otherwise occur in open air, compromising the final product's integrity.

The true value of a vacuum furnace in sintering is not just the heat it applies, but the pristine environment it creates. By eliminating atmospheric variables, it allows materials to achieve a level of purity, density, and structural integrity that is simply not possible with conventional heating methods.

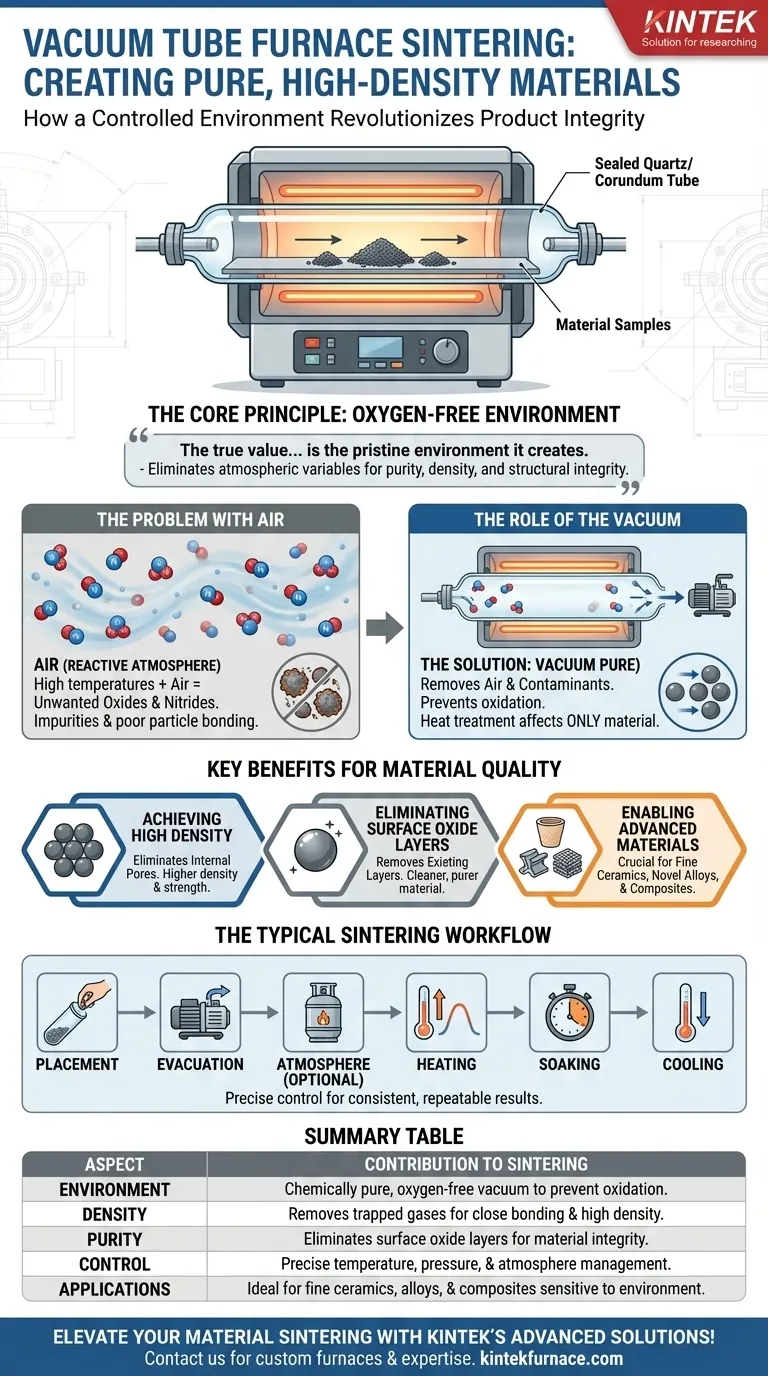

The Core Principle: Sintering in a Controlled Environment

Sintering is a thermal process for compacting and forming a solid mass of material by heat, but without melting it to the point of liquefaction. A vacuum tube furnace perfects this process by controlling the chemical environment in which it happens.

The Problem with Air

Most sintering processes fail in open air because of a simple fact: air, particularly its oxygen and nitrogen content, is highly reactive at high temperatures. This causes the formation of unwanted oxides and nitrides on the material's surface, preventing particles from bonding effectively and introducing impurities.

The Role of the Vacuum

A vacuum tube furnace solves this by first removing the air. The process involves placing the material inside a sealed tube, typically made of quartz or corundum, which is then evacuated by a vacuum pump.

By removing the atmosphere, the furnace eliminates the risk of contamination and oxidation. This creates a clean slate, ensuring the heat treatment affects only the material itself.

The Importance of a Sealed System

The entire process relies on an airtight system. This is achieved using a high-purity tube sealed at the ends with stainless steel flanges. This sealed container ensures that once the vacuum is established, no external contaminants can enter the chamber during the sensitive heating and cooling phases.

Key Benefits for Material Quality

Using a vacuum environment is not just about prevention; it enables the creation of superior materials with specific, desirable properties.

Achieving High Density

In a vacuum, any gases trapped between the material particles are pulled out. This allows the particles to move closer together and bond more efficiently during heating, eliminating internal pores and resulting in a final product with significantly higher density and strength.

Eliminating Surface Oxide Layers

Many materials, especially metals, naturally have a thin oxide layer on their surface. The vacuum environment, combined with high heat, can help remove these existing layers while preventing new ones from forming. This leads to a cleaner, more pure material with better performance characteristics.

Enabling Advanced Materials

This technology is crucial for the production of advanced materials that are highly sensitive to their environment. This includes fine ceramics (like aluminum nitride and silicon nitride), novel metal alloys, and specialized composites that would be impossible to synthesize in the presence of oxygen.

Understanding the Process and Its Control

The effectiveness of vacuum sintering comes from its high degree of process control. It is not a simple "heat and cool" operation.

Precise Temperature and Pressure Control

These furnaces offer exceptionally precise control over the heating rate, holding temperature, and cooling rate. This ensures that the sintering process is consistent and repeatable, which is critical for both research experiments and high-quality industrial production. Some furnaces also apply high pressure to further aid densification.

The Option for Controlled Atmospheres

Creating a vacuum is often just the first step. After evacuation, a specific gas, such as hydrogen or argon, can be introduced into the chamber. This allows for a reactive sintering process, where the controlled atmosphere actively participates in the material's chemical transformation in a predictable way.

The Typical Sintering Workflow

- Placement: The sample material is placed inside the sealed tube.

- Evacuation: A vacuum pump removes the air from the tube.

- Atmosphere: Optionally, a specific process gas is introduced to a set pressure.

- Heating: The heating elements are activated, following a programmed temperature profile.

- Soaking: The furnace holds the material at the peak sintering temperature for a set duration.

- Cooling: The furnace is allowed to cool down, often in a controlled manner, before the sample is removed.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace for sintering is driven by the desired outcome for the material.

- If your primary focus is maximum material purity and density: A vacuum furnace is essential for removing trapped gases and preventing the introduction of atmospheric contaminants.

- If your primary focus is processing oxygen-sensitive metals or ceramics: The oxygen-free environment is non-negotiable to prevent a destructive oxidation reaction that would ruin the material.

- If your primary focus is developing novel alloys or composites: The precise control over both temperature and atmosphere provides the unique conditions required for synthesizing advanced materials.

Ultimately, the vacuum tube furnace is an indispensable tool for moving beyond simple heating and into the realm of true material science.

Summary Table:

| Aspect | Contribution to Sintering |

|---|---|

| Environment | Creates a chemically pure, oxygen-free vacuum to prevent oxidation and contamination. |

| Density | Removes trapped gases, allowing particles to bond closely for high-density products. |

| Purity | Eliminates surface oxide layers, ensuring material integrity and advanced properties. |

| Control | Offers precise temperature, pressure, and atmosphere management for repeatable results. |

| Applications | Ideal for fine ceramics, metal alloys, and composites sensitive to environmental factors. |

Elevate your material sintering with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Vacuum Tube Furnaces tailored for your unique needs. Whether you're working with ceramics, alloys, or composites, our deep customization ensures precise control for pure, dense outcomes. Contact us today to discuss how our expertise can enhance your lab's efficiency and product quality!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity