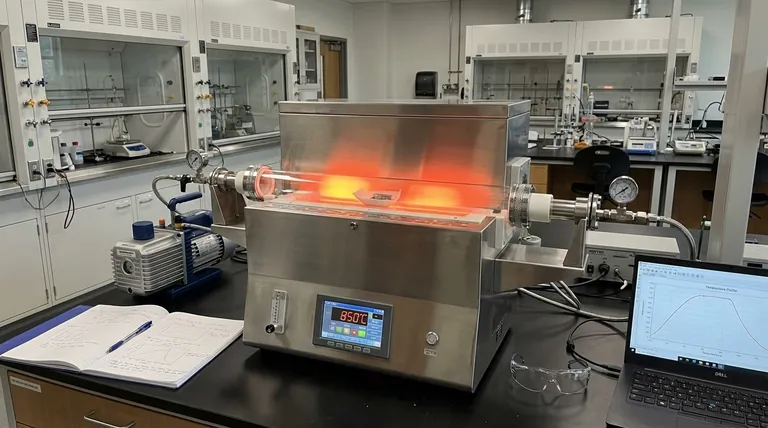

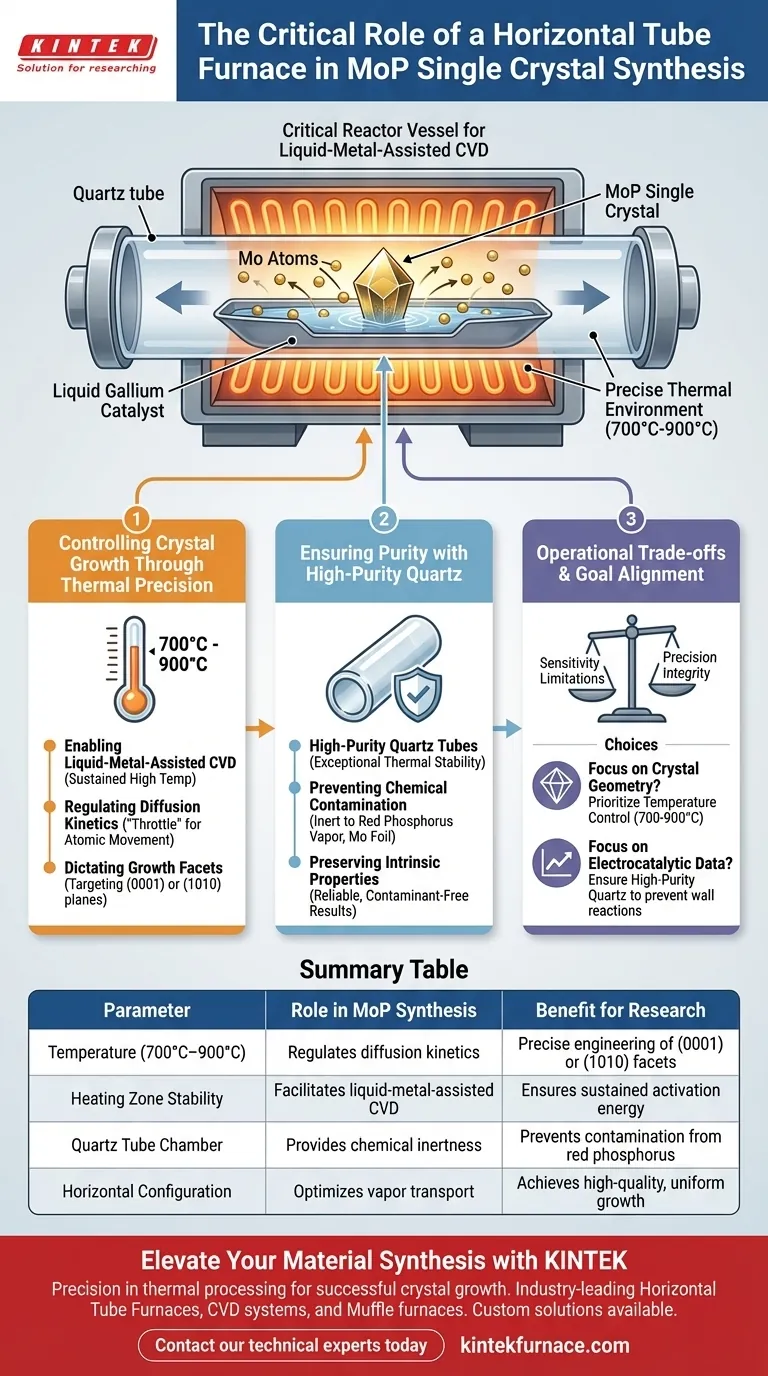

A Horizontal Tube Furnace acts as the critical reactor vessel for the synthesis of Molybdenum Phosphide (MoP) single crystals. It provides the precise thermal environment necessary to drive liquid-metal-assisted Chemical Vapor Deposition (CVD), ensuring controlled atomic diffusion and crystal formation.

The furnace is not merely a heat source; it is a tool for kinetic control. By maintaining precise temperatures between 700°C and 900°C, it regulates how molybdenum atoms diffuse across liquid gallium, allowing researchers to dictate the specific geometric growth facets of the final crystal.

Controlling Crystal Growth Through Thermal Precision

Enabling Liquid-Metal-Assisted CVD

The primary function of the furnace is to facilitate liquid-metal-assisted Chemical Vapor Deposition (CVD).

This synthesis method requires a sustained, high-temperature environment to activate the reaction. The furnace provides the stable heating zone necessary to maintain the metal catalyst in a liquid state.

Regulating Diffusion Kinetics

The furnace plays a decisive role in managing the diffusion kinetics of the reaction.

By operating within a specific window of 700°C to 900°C, the system controls the speed at which molybdenum atoms move across the liquid gallium surface. This thermal regulation is the "throttle" for atomic movement.

Dictating Growth Facets

Precise temperature control allows for the selective engineering of the crystal's physical structure.

By adjusting the heat within the specified range, researchers can preferentially grow specific crystal planes. This capability is essential for targeting the (0001) or (1010) facets in MoP crystals.

Ensuring Purity with the Right Chamber Material

The Importance of High-Purity Quartz

The horizontal configuration utilizes high-purity quartz tubes as the reaction chamber.

These tubes provide exceptional thermal stability, allowing the system to withstand the rigorous heating cycles required for synthesis without structural failure.

Preventing Chemical Contamination

The chemical inertness of the quartz tube is vital for protecting the reactants.

It prevents chemical reactions between the chamber walls and volatile components like red phosphorus vapor or the molybdenum foil itself. This isolation is critical for maintaining the integrity of the chemical precursors.

Preserving Intrinsic Properties

A contaminant-free environment ensures the reliability of the final material.

By eliminating impurities derived from the reactor walls, the resulting MoP single crystals accurately reflect their intrinsic electrocatalytic properties.

Understanding the Operational Trade-offs

Sensitivity to Temperature Fluctuations

While the furnace allows for precision, the process is highly sensitive to thermal instability.

Deviating even slightly from the 700°C to 900°C range can disrupt the diffusion kinetics. This can result in uncontrolled growth or the formation of incorrect crystal facets.

Material Limitations

The reliance on high-purity quartz imposes strict limits on the chemical environment.

While quartz is inert to phosphorus and molybdenum, it may degrade if exposed to incompatible agents or temperatures exceeding its softening point. The purity of the crystal is entirely dependent on the integrity of the tube.

Making the Right Choice for Your Goal

To maximize the quality of your Molybdenum Phosphide synthesis, you must align your furnace parameters with your specific research objectives.

- If your primary focus is Crystal Geometry: Prioritize the precision of your temperature controller to target the specific 700°C–900°C range required for (0001) or (1010) facet growth.

- If your primary focus is Electrocatalytic Data: Ensure you are using high-purity quartz tubes to prevent wall reactions and guarantee the measured properties are intrinsic to the material.

Ultimately, the Horizontal Tube Furnace converts raw thermal energy into a precise instrument for atomic engineering.

Summary Table:

| Parameter | Role in MoP Synthesis | Benefit for Research |

|---|---|---|

| Temperature (700°C–900°C) | Regulates diffusion kinetics across liquid gallium | Precise engineering of (0001) or (1010) facets |

| Heating Zone Stability | Facilitates liquid-metal-assisted CVD | Ensures sustained activation energy for reaction |

| Quartz Tube Chamber | Provides chemical inertness and thermal stability | Prevents contamination from red phosphorus vapor |

| Horizontal Configuration | Optimizes vapor transport of precursors | Achieves high-quality, uniform single crystal growth |

Elevate Your Material Synthesis with KINTEK

Precision in thermal processing is the difference between a successful crystal growth and a failed experiment. KINTEK provides industry-leading Horizontal Tube Furnaces, CVD systems, and Muffle furnaces designed to meet the rigorous demands of advanced material research.

Backed by expert R&D and manufacturing, our systems offer the thermal stability and atmospheric control necessary for targeting specific crystal facets and ensuring high-purity results. Whether you require standard lab high-temp furnaces or fully customizable solutions for unique MoP synthesis needs, KINTEK is your partner in laboratory excellence.

Ready to optimize your CVD process? Contact our technical experts today to discuss your specific requirements.

Visual Guide

References

- Seo Hyun Kim, Hyeuk Jin Han. Facet‐Controlled Growth of Molybdenum Phosphide Single Crystals for Efficient Hydrogen Peroxide Synthesis. DOI: 10.1002/adma.202500250

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Why is a high-temperature tube furnace required for Ti3AuC2 annealing? Achieve Perfect Atomic Exchange

- What is the function of sealed quartz ampoules in Se80In5Te6Sb9 synthesis? Ensure Purity and Precision

- Why is an atmosphere-controlled tube furnace used for La-CoTe2 synthesis? Master Your Tellurization Process Today

- In which fields are fluidized bed vertical tube furnaces commonly applied? Explore Key Uses in Materials Science and Energy

- What environmental parameters must high-temperature furnaces maintain for YIG thin film annealing? Expert Guide

- What technical requirements must a laboratory tube furnace meet for SOFC testing? Ensure Precise Fuel Cell Analysis

- Why is a tube furnace considered essential for metal-zeolite catalysts? Unlock Porosity and Active Sites

- How are rotary tube furnaces used in the mining and metallurgy industry? Boost Efficiency in Metal Processing