Fluidized bed vertical tube furnaces are specialized tools applied across materials science, chemical engineering, energy production, and environmental management. Their unique design makes them indispensable for processes requiring uniform heating of granular materials, such as powder metallurgy, catalytic cracking, and high-efficiency incineration.

The defining advantage of a fluidized bed vertical tube furnace is its ability to achieve exceptionally uniform and efficient heat transfer to granular or powdered materials. This makes it the ideal choice for processes where precise temperature control and consistent treatment of fine particles are non-negotiable.

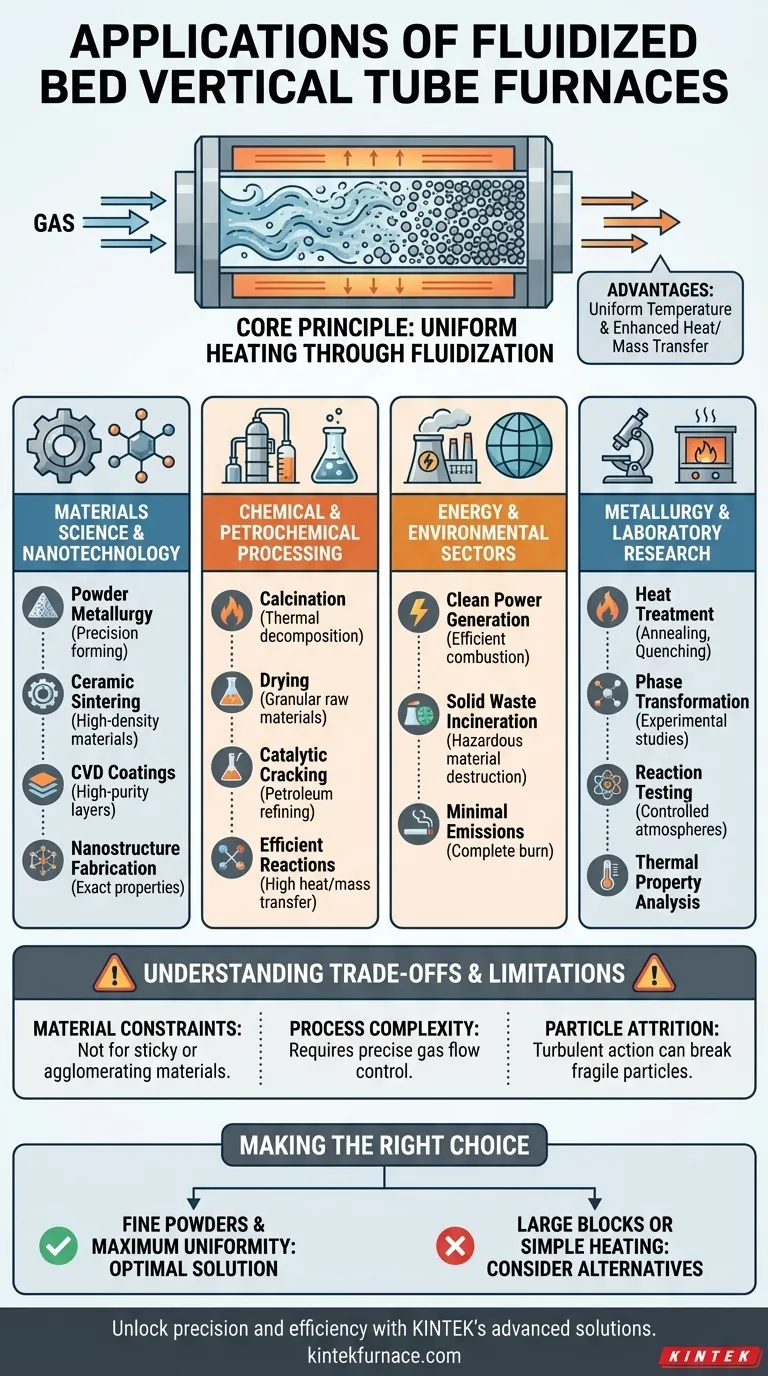

The Core Principle: Why Fluidization Matters

To understand the applications of this furnace, you must first understand its core mechanism. It's not just a vertical tube that gets hot; it's an active system that transforms the material inside it.

What Is a Fluidized Bed?

A fluidized bed is created when a flow of gas is passed upward through a bed of solid particles. At a specific gas velocity, the particles become suspended, separating them and causing them to behave with the properties of a liquid.

This "fluid-like" state is the key to the furnace's performance. The material is no longer a static pile but a turbulent, constantly mixing volume.

The Advantage of Uniform Temperature

In a standard furnace, heating a pile of powder is inefficient. The particles on the outside get hotter than those in the center, creating a significant temperature gradient that leads to inconsistent results.

In a fluidized bed, the constant motion of the particles ensures that heat is distributed almost instantaneously throughout the entire volume. This eliminates hot spots and guarantees that every particle experiences the same temperature profile.

Enhanced Heat and Mass Transfer

The turbulent mixing dramatically increases the surface area of the particles exposed to the process gas and heat. This massively accelerates the rate of heat transfer into the particles and enhances the efficiency of chemical reactions, drying, or phase changes.

Key Applications by Industry

The unique benefits of fluidization make these furnaces the superior choice for specific, high-value processes in several key industries.

In Materials Science and Nanotechnology

This field demands precision. The furnace's uniform temperature is critical for creating advanced materials with predictable properties.

Applications include powder metallurgy, ceramic sintering, and producing high-purity coatings via Chemical Vapor Deposition (CVD). It is also essential for fabricating nanostructures and other electronic components where even minor temperature deviations can cause defects.

In Chemical and Petrochemical Processing

The chemical industry relies on this technology for reactions involving solid catalysts or reactants. The high heat and mass transfer rates lead to greater efficiency and yield.

Key uses are the calcination (thermal decomposition) and drying of granular raw materials, as well as large-scale processes like catalytic cracking in petroleum refining to produce gasoline.

In Energy and Environmental Sectors

Efficient combustion is the primary goal in these applications. The fluidized bed ensures that fuel particles are completely and efficiently burned.

These furnaces are used in coal-fired power plants for clean and efficient power generation. They are also highly effective for the incineration of solid waste, ensuring complete destruction of hazardous materials with minimal harmful emissions.

In Metallurgy and Laboratory Research

In metallurgy, these furnaces are used for precise heat treatment processes like annealing and quenching of metal powders.

In the laboratory, they provide researchers with a highly controlled environment to study material thermal properties, conduct phase transformation experiments, and test reactions under specific atmospheres, such as inert gas or air.

Understanding the Trade-offs and Limitations

While powerful, this technology is not universally applicable. Understanding its limitations is critical for making an informed decision.

Material Constraints

The furnace is only suitable for materials that can be successfully fluidized. Materials that are very sticky, have a tendency to agglomerate, or have an extremely wide particle size distribution may not perform well.

Process Complexity

Maintaining a stable fluidized bed requires precise control over gas flow rates. The system is mechanically more complex than a simple static furnace, which can translate to higher initial and maintenance costs.

Particle Attrition and Elutriation

The turbulent action can cause fragile particles to break down (attrition). Furthermore, very fine particles can be carried out of the furnace by the fluidizing gas (elutriation), often requiring downstream equipment like cyclones for capture and recovery.

Making the Right Choice for Your Process

Deciding if this technology is appropriate depends entirely on the nature of your material and your processing goals.

- If your primary focus is processing fine powders or granules with maximum temperature uniformity: This technology is the optimal solution for achieving consistent, high-quality results.

- If your primary focus is high-efficiency combustion or catalytic reactions: The enhanced heat and mass transfer of a fluidized bed offers significant performance advantages over static systems.

- If you are working with large solid blocks, sticky materials, or require the simplest heating method: You should first evaluate alternatives like a conventional muffle or static tube furnace.

By understanding its core principle of fluidization, you can confidently determine where this powerful technology fits within your technical roadmap.

Summary Table:

| Field | Key Applications |

|---|---|

| Materials Science & Nanotechnology | Powder metallurgy, ceramic sintering, Chemical Vapor Deposition (CVD), nanostructure fabrication |

| Chemical & Petrochemical Processing | Calcination, drying, catalytic cracking in petroleum refining |

| Energy & Environmental Sectors | Coal-fired power generation, incineration of solid waste |

| Metallurgy & Laboratory Research | Heat treatment (e.g., annealing, quenching), phase transformation experiments, reaction testing |

Unlock precision and efficiency in your processes with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs. Contact us today to discuss how our fluidized bed vertical tube furnaces can enhance your material processing and achieve superior results!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Why is uniform heating important in tubular furnaces? Ensure Process Reliability and Predictable Results

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What materials are used for the tube chamber in tubular furnaces? Choose the Right Tube for Your Lab's High-Temp Needs