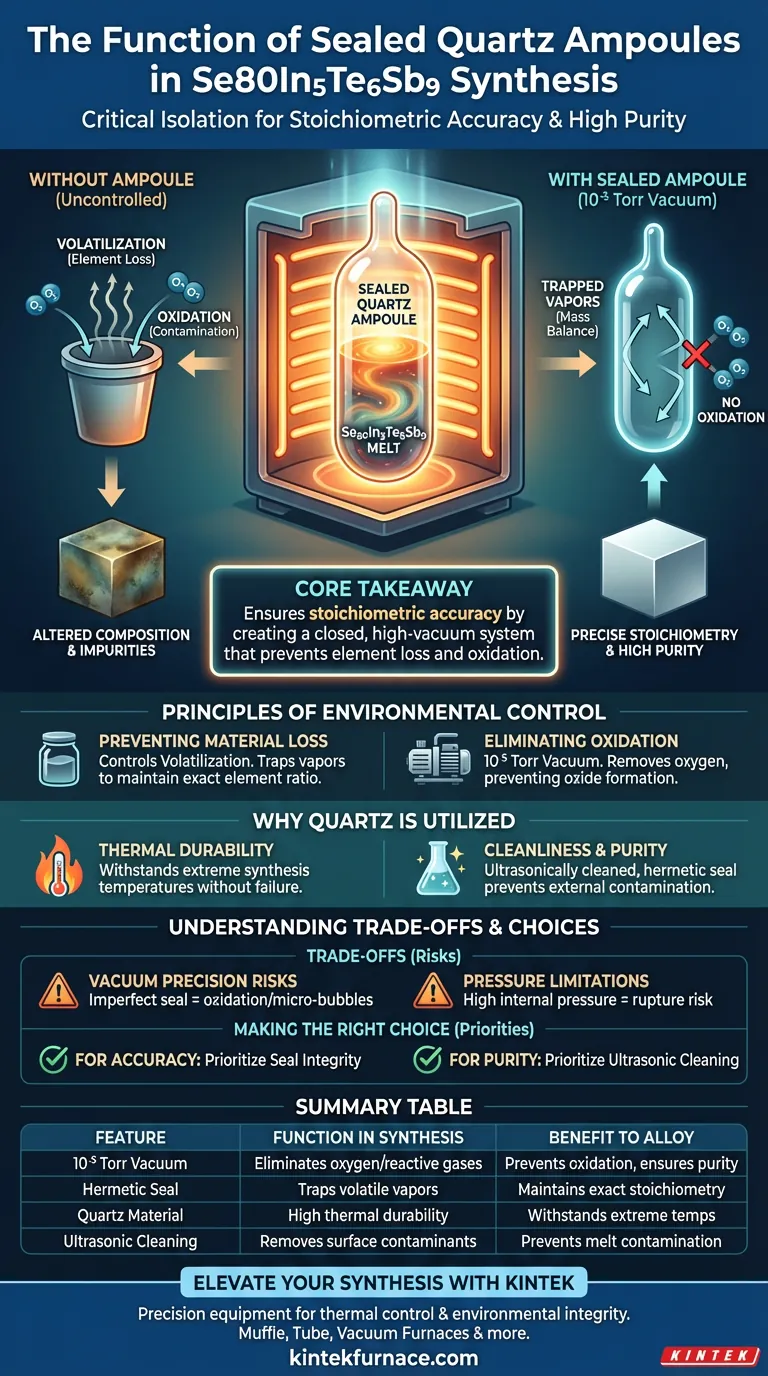

Sealed quartz ampoules serve as a critical isolation chamber during the high-temperature synthesis of Se80In5Te6Sb9. Their primary function is to maintain a high-vacuum environment (specifically at 10⁻⁵ Torr) that withstands extreme heat while physically isolating the raw materials. This setup is essential for preventing chemical alteration of the alloy through oxidation or loss of material.

Core Takeaway: The sealed quartz ampoule guarantees the stoichiometric accuracy of the final alloy. It acts as a closed system that prevents volatile elements from escaping and blocks oxygen from contaminating the melt, ensuring the material remains pure and chemically precise.

The Principles of Environmental Control

Preventing Material Loss

In alloy synthesis, particularly with complex compositions like Se80In5Te6Sb9, maintaining the exact ratio of elements is vital.

Controlling Volatilization

High processing temperatures can cause specific constituent elements to vaporize or volatilize.

Without a sealed environment, these vapors would escape, altering the final chemical composition (stoichiometry) of the alloy. The ampoule traps these vapors, keeping the mass balance intact.

Eliminating Oxidation

At elevated temperatures, raw materials are highly susceptible to reacting with oxygen in the air.

By vacuum-sealing the ampoule at 10⁻⁵ Torr, the process removes potential oxidizers. This effectively prevents the formation of oxides which would degrade the purity and performance of the final alloy.

Why Quartz is Utilized

Thermal Durability

The synthesis process requires melting materials at high temperatures.

Quartz is selected because it acts as a robust vessel designed to withstand these high temperatures without structural failure.

Cleanliness and Purity

Before use, these ampoules are ultrasonically cleaned to remove microscopic contaminants.

This cleaning, combined with the material properties of quartz, provides a hermetically sealed micro-environment. This barrier ensures that no external contaminants can enter the melt during the heating phase.

Understanding the Trade-offs

Vacuum Precision Risks

Achieving a vacuum of 10⁻⁵ Torr requires precise equipment and technique.

If the seal is imperfect or the vacuum is insufficient, trace amounts of gas may remain. This can lead to minor oxidation or "micro-bubbles" in the alloy, compromising its structural integrity.

Pressure Limitations

While quartz handles heat well, it is a brittle material.

If the internal pressure from volatilized elements becomes too high during the melt, the ampoule risks rupturing. The wall thickness and quartz quality must be carefully matched to the expected vapor pressure of the specific elements involved.

Making the Right Choice for Your Goal

To ensure the successful synthesis of Se80In5Te6Sb9, consider your specific priorities:

- If your primary focus is compositional accuracy: Prioritize the integrity of the vacuum seal to prevent the volatilization of lighter elements, ensuring the final ratio matches the initial weight.

- If your primary focus is material purity: Ensure the quartz ampoules are ultrasonically cleaned and handled in a controlled environment before loading to eliminate surface contaminants.

The sealed quartz ampoule is the fundamental tool for converting raw elements into a precise, high-purity alloy without environmental interference.

Summary Table:

| Feature | Function in Synthesis | Benefit to Se80In5Te6Sb9 Alloy |

|---|---|---|

| 10⁻⁵ Torr Vacuum | Eliminates oxygen and reactive gases | Prevents oxidation and ensures material purity |

| Hermetic Seal | Traps volatile constituent vapors | Maintains exact stoichiometric accuracy |

| Quartz Material | Provides high thermal durability | Withstands extreme synthesis temperatures without failure |

| Ultrasonic Cleaning | Removes microscopic surface contaminants | Prevents external contamination of the melt |

Elevate Your Material Synthesis with KINTEK

Precision in alloy development like Se80In5Te6Sb9 requires uncompromising thermal control and environmental integrity. KINTEK provides the specialized equipment needed to master these variables. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique research requirements.

Ready to ensure the stoichiometric accuracy and purity of your next project? Contact our experts today to find the perfect high-temperature solution for your laboratory.

Visual Guide

References

- Studies on phase change Se80In5Te6Sb9 thin films by -irradiation for optoelectronic devices. DOI: 10.56975/jetir.v12i1.563335

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What are the main operational considerations when using a lab tube furnace? Ensure Precision and Safety in Your Experiments

- Is it safe to use a quartz tube furnace at high temperatures? Ensure Safety with the Right Tube Material

- What safety protection mechanisms are typically included in tube furnaces? Ensure Operator and Equipment Safety

- What is the function of a double-zoned tube furnace in CVD of 2DP-F films? Unlock Precise Thin-Film Growth Control

- What is the primary function of a tube furnace in the pyrolysis of biomass? Achieve Precision in Material Research

- What is the function of a laboratory tube furnace in Ti-5Al-4W-2Fe alloy forging? Enhance Thermoplasticity & Purity

- Why is it necessary to use a tube furnace with an inert atmosphere for the thermal debinding of ceramic green bodies?

- What are the key factors to consider when choosing a vertical tube furnace? Ensure Optimal Performance for Your Lab