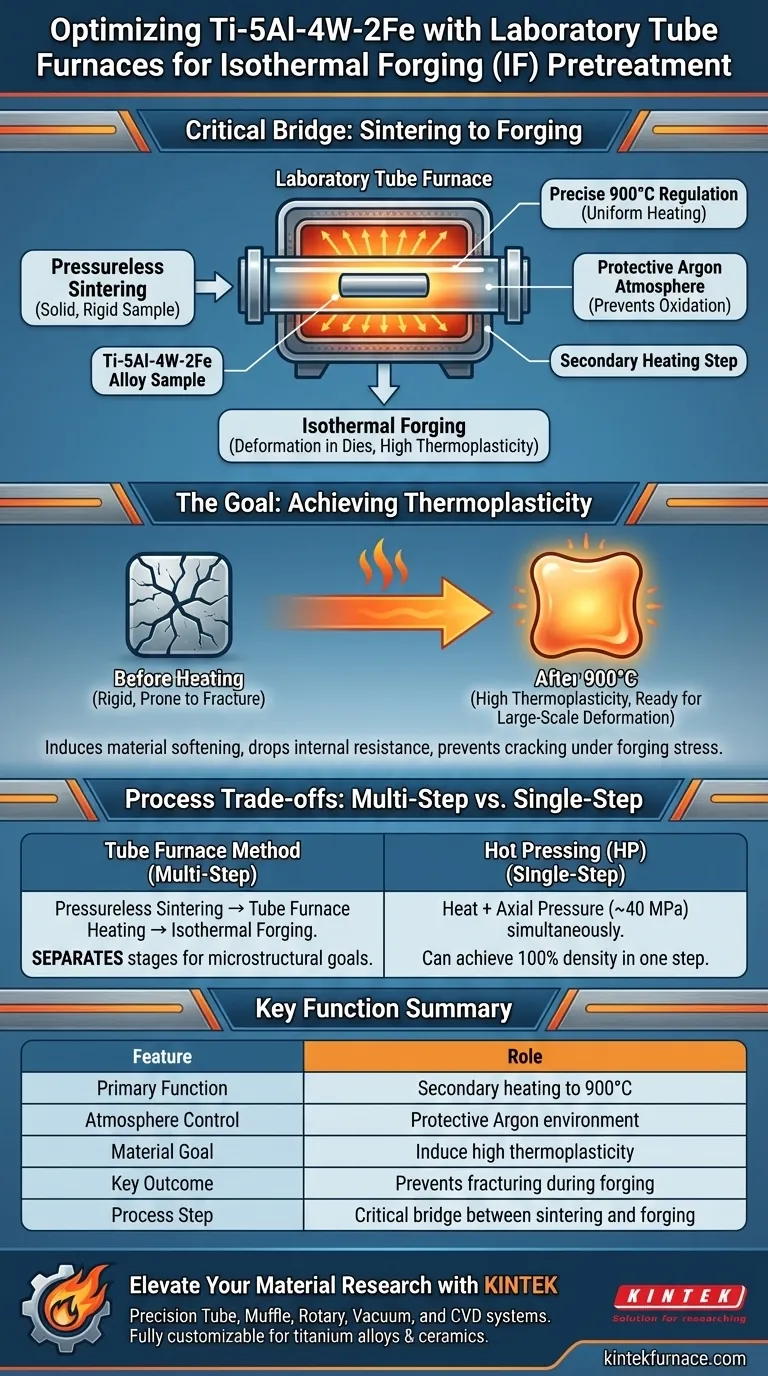

The primary function of a laboratory tube furnace in this context is to perform secondary heating. This unit processes Ti-5Al-4W-2Fe alloy samples that have previously undergone pressureless sintering. Specifically, it heats these samples to exactly 900°C under a protective argon atmosphere to prepare them for physical deformation.

The tube furnace acts as the bridge between sintering and forging. By stabilizing the alloy at 900°C, it ensures the material achieves the high thermoplasticity required to withstand large-scale deformation in specialized forging dies without fracturing.

The Objective: Achieving Thermoplasticity

Inducing Material Softening

The core purpose of this heating stage is to bring the Ti-5Al-4W-2Fe alloy into a state of high thermoplasticity.

After pressureless sintering, the material is solid but may be too rigid for complex shaping.

The tube furnace heats the alloy to a point where its internal resistance to deformation drops significantly.

Preparation for Large-Scale Deformation

This pretreatment is not the final forming step; it is a pre-requisite for isothermal forging.

The furnace ensures the sample is thermally conditioned so that when it enters the forging dies, it flows correctly.

Without this specific thermal preparation, the alloy would likely crack or fail under the mechanical stress of forging.

Operational Environment and Control

Precise Temperature Regulation

The furnace must maintain a precise temperature of 900°C.

While other titanium alloys may require different solution or aging temperatures (e.g., 750°C or 510°C), this specific alloy requires 900°C for optimal forging readiness.

This precision ensures uniform heating, which is critical for consistent behavior during the subsequent forging process.

Oxidation Prevention

The process is conducted under a protective argon atmosphere.

Titanium alloys are highly reactive to oxygen at elevated temperatures.

The tube furnace's sealed environment prevents surface oxidation, preserving the chemical integrity of the alloy before it undergoes mechanical work.

Understanding the Process Trade-offs

Multi-Step vs. Single-Step Processing

Using a tube furnace implies a multi-step approach: Pressureless Sintering $\rightarrow$ Tube Furnace Heating $\rightarrow$ Isothermal Forging.

This differs from Hot Pressing (HP), where heat and axial pressure (approx. 40 MPa) are applied simultaneously to powder.

While HP can achieve 100% theoretical density in a single step, the tube furnace method is necessary when separating the sintering and forging stages is required for specific microstructural goals.

Density Limitations

The tube furnace itself does not significantly densify the material; it only heats it.

Pressureless sintering often leaves residual internal pores.

The tube furnace merely prepares the material for the forging step, which is the mechanism responsible for closing these pores and achieving final density.

Making the Right Choice for Your Goal

To optimize the processing of Ti-5Al-4W-2Fe, consider the following based on your specific objectives:

- If your primary focus is preventing material failure during forging: Ensure the tube furnace maintains a strict 900°C profile to guarantee maximum thermoplasticity.

- If your primary focus is surface integrity: Verify the argon flow rate within the tube furnace is sufficient to prevent the formation of a brittle alpha-case layer caused by oxidation.

- If your primary focus is maximum densification: Recognize that the tube furnace is only a preparatory step; the subsequent isothermal forging pressure is what effectively closes internal voids.

The tube furnace is not just a heater; it is the critical control point that safeguards the alloy's plasticity and purity immediately before deformation.

Summary Table:

| Feature | Role in Ti-5Al-4W-2Fe Pretreatment |

|---|---|

| Primary Function | Secondary heating of sintered samples to 900°C |

| Atmosphere Control | Protective Argon environment to prevent oxidation |

| Material Goal | Inducing high thermoplasticity for deformation |

| Key Outcome | Prevents fracturing during subsequent isothermal forging |

| Process Step | Critical bridge between sintering and physical forging |

Elevate Your Material Research with KINTEK

Ready to achieve perfect thermoplasticity in your advanced alloys? Backed by expert R&D and manufacturing, KINTEK offers precision Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific temperature and atmospheric requirements. Whether you are processing titanium alloys or developing new ceramics, our lab high-temperature furnaces provide the uniform control you need to ensure consistent results.

Contact KINTEK Today to Find Your Custom Heating Solution

Visual Guide

References

- Mai Essam, Nabil Fatahalla. Processing of Ti–5Al–4W–2Fe Alloy Using Different Powder Metallurgy Routes to Improve Its Implementation in Structural Applications. DOI: 10.1007/s13369-024-09834-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a tubular furnace work? Achieve Precise, Uniform Heat for Your Lab

- What is the purpose of using a high-temperature tube furnace with a steam generator for LOCA simulation?

- How do tube furnaces contribute to transport reactions and crystal production? Master High-Purity Synthesis with Precision Control

- What is the function of a double-temperature zone tube furnace in CVD synthesis of 2D epsilon-Fe2O3 nanosheets?

- What role does a high-temperature tube furnace play in biomass carbon skeletons? Master Structural Integrity.

- What is the function of a tube reactor during the reduction process of Siderite Ore? Optimize Your Metallization Process

- In what settings are both tube and box furnaces commonly used? Optimize Your Thermal Processes with the Right Choice

- What physical conditions does a high-temperature tube furnace provide? Optimize Lignin Carbonization Success