At its core, a tubular furnace works by passing electricity through heating elements that surround a central, cylindrical tube. A sample placed inside this tube is heated in a highly uniform and controlled environment. This entire process is governed by a precise temperature controller that dictates the heating rate, target temperature, and duration of the thermal cycle.

The true value of a tubular furnace isn't just its ability to get hot, but its design, which creates an exceptionally uniform and controllable thermal processing zone. This makes it indispensable for applications where temperature consistency is critical.

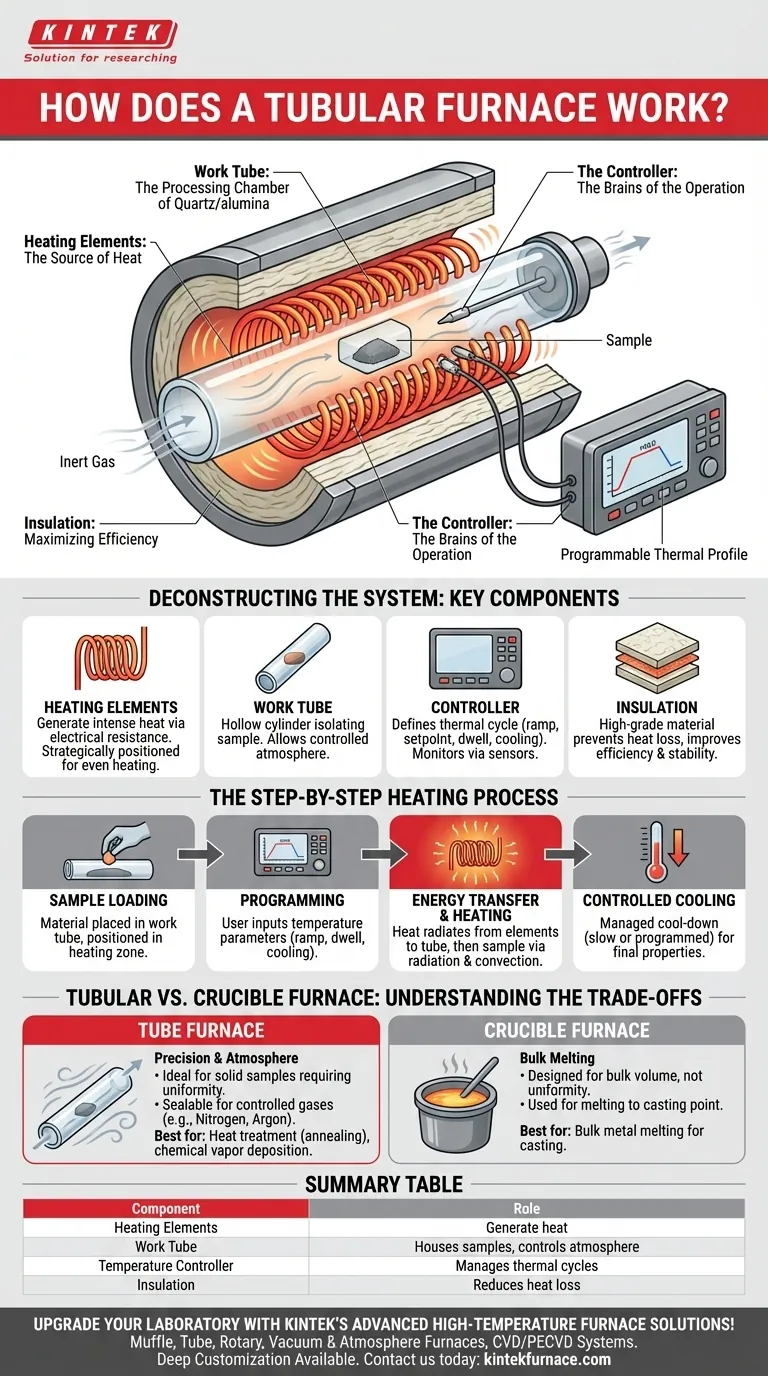

Deconstructing the System: Key Components and Their Roles

To understand how a tubular furnace achieves such precision, we must look at its core components. Each part is engineered to contribute to a stable and predictable heating environment.

The Heating Elements: The Source of Heat

The engine of the furnace is its set of electrical heating elements. When current passes through these elements, their natural resistance generates intense heat. They are strategically positioned to encircle the work tube, ensuring heat is applied evenly from all directions.

The Work Tube: The Processing Chamber

This is the central, hollow cylinder—often made of quartz, alumina, or mullite—that houses the material to be heated. The tube isolates the sample, protecting it from direct contact with the heating elements and containing any required atmospheric gases.

The Controller: The Brains of the Operation

The temperature controller is the command center. Here, a user defines the entire thermal profile: the rate of temperature increase (ramp rate), the final temperature (setpoint), how long to hold it (dwell time), and the cooling sequence. It uses a sensor, like a thermocouple, to constantly monitor the temperature and adjust power to the elements.

The Insulation: Maximizing Efficiency

High-grade thermal insulation material encases the heating elements and tube assembly. Its purpose is to prevent heat from escaping into the laboratory, which improves energy efficiency, protects the user, and contributes to a more stable internal temperature.

The Step-by-Step Heating Process

The operation of a tubular furnace follows a logical and repeatable sequence, designed for precision and safety.

Step 1: Sample Loading

First, the material or sample is carefully placed inside the work tube. The tube is then positioned correctly within the furnace's heating zone.

Step 2: Programming the Thermal Cycle

The user inputs the desired temperature parameters into the controller. For sensitive processes like sintering or annealing, this involves programming multiple heating, holding, and cooling steps.

Step 3: Energy Transfer and Heating

Once initiated, the controller sends power to the heating elements. Heat is transferred from the elements to the outer wall of the work tube, primarily through radiation. The tube wall then heats the sample inside through a combination of radiation and convection within the gas-filled tube.

Step 4: Controlled Cooling

Just as important as heating, the cooling phase is also managed by the controller. This can be a slow, natural cool-down or a programmed ramp-down, which is critical for controlling the final properties and microstructure of many materials.

Understanding the Trade-offs: Tube vs. Other Furnaces

The tubular furnace is a specialized tool. Its design makes it ideal for some tasks but less suitable for others. A common point of comparison is the crucible furnace.

When to Use a Tube Furnace: Precision and Atmosphere

The long, enclosed chamber of a tube furnace is perfect for processing solid samples that require exceptional temperature uniformity. Its key advantage is the ability to seal the ends and flow a specific gas (like nitrogen or argon) through the tube, creating a controlled, non-oxidizing, or reactive atmosphere.

When to Use a Crucible Furnace: Bulk Melting

A crucible furnace, by contrast, is designed to hold a pot (the crucible) in a heated chamber. Its purpose is not uniformity along a length, but simply to heat a bulk volume of material, usually to its melting point for casting. It is a tool for bulk processing, not precision treatment.

Making the Right Choice for Your Application

Selecting the correct heating equipment is fundamental to achieving your desired outcome. Use your primary goal to guide your decision.

- If your primary focus is precise heat treatment of a solid sample (e.g., annealing, tempering): The tube furnace's superior temperature uniformity is essential for repeatable results.

- If your primary focus is synthesizing materials in a controlled atmosphere (e.g., chemical vapor deposition): The sealable design of a tube furnace makes it the standard and necessary tool.

- If your primary focus is melting a bulk quantity of metal for casting into a mold: A crucible furnace is the simpler, more effective, and purpose-built choice.

Ultimately, understanding the fundamental design of your tools empowers you to select the right one for the job, ensuring both efficiency and success.

Summary Table:

| Component | Role |

|---|---|

| Heating Elements | Generate heat through electrical resistance, surrounding the tube for even distribution |

| Work Tube | Houses samples, made of materials like quartz or alumina, and allows for atmosphere control |

| Temperature Controller | Manages heating rates, setpoints, and cooling cycles using sensors for precision |

| Insulation | Reduces heat loss, improves efficiency, and maintains stable internal temperatures |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior performance and reliability. Contact us today to discuss how our tailored solutions can optimize your thermal processes and drive success in your research or production.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents